Konjac glucomannan separation method and device

A mannan and separation device technology, applied in the field of konjac glucomannan separation method and its device, can solve the problem of high content of sulfur dioxide and achieve the effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

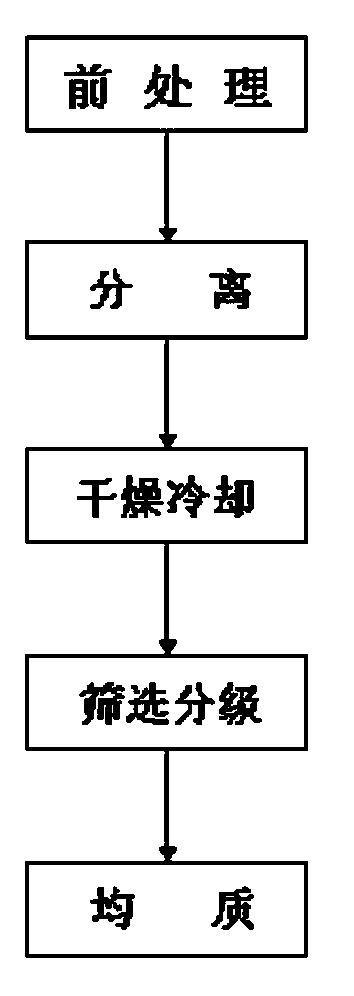

[0038] Put 200 Kg of konjac fine powder in 28% alcohol with a volume ratio of 4 times, stir and soak for 1 hour, enter the cyclone for ladder washing and desulfurization in the forward and reverse directions, and separate through the high-pressure cyclone reverse rolling continuous separation device to obtain 180Kg konjac Glucomannan (including secondary cyclone recovery section). Konjac glucomannan is dried to a moisture content of 8% and then cooled. After screening, grading, mixing and homogenization, the finished product of konjac glucomannan is obtained. The content of glucomannan is 90% after inspection, and the activity of glucomannan ( Viscosity (mpa.s) is 36000, sulfur dioxide content g / kg is 243ppm.

Embodiment 2

[0040] Put 200 Kg of konjac fine powder in 45% alcohol with a concentration of 3 times the volume ratio, stir and soak for 3 hours, enter the cyclone for ladder washing and desulfurization in the forward and reverse directions, and separate through the high-pressure cyclone reverse rolling continuous separation device to obtain 182Kg konjac Glucomannan (including secondary cyclone recovery section). Konjac glucomannan is dried to a moisture content of 10% and then cooled. After screening, grading, mixing and homogenization, the finished product of konjac glucomannan is obtained. The content of glucomannan is 95% after inspection, and the activity of glucomannan ( Viscosity (mpa.s) is 36050, sulfur dioxide content g / kg is 251ppm.

Embodiment 3

[0042] Put 200 Kg of konjac fine powder in 20% alcohol with a volume ratio of 4 times, stir and soak for 2 hours, enter the cyclone for ladder washing and desulfurization in the forward and reverse directions, and separate through the high-pressure cyclone reverse rolling continuous separation device to obtain 177Kg konjac Glucomannan (including secondary cyclone recovery section). Konjac glucomannan is dried to a moisture content of 9% and then cooled. After screening, grading, mixing and homogenization, the finished product of konjac glucomannan is obtained. The content of glucomannan is 93% after inspection, and the activity of glucomannan ( Viscosity (mpa.s) is 36200, sulfur dioxide content g / kg is 285ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com