Noise reduction damping paste and preparation method thereof

A damping paste and noise reduction technology, applied in the field of damping paste, can solve problems such as noise pollution, machine wear, low toxicity, etc., and achieve excellent damping, vibration reduction, noise reduction, structural vibration suppression, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

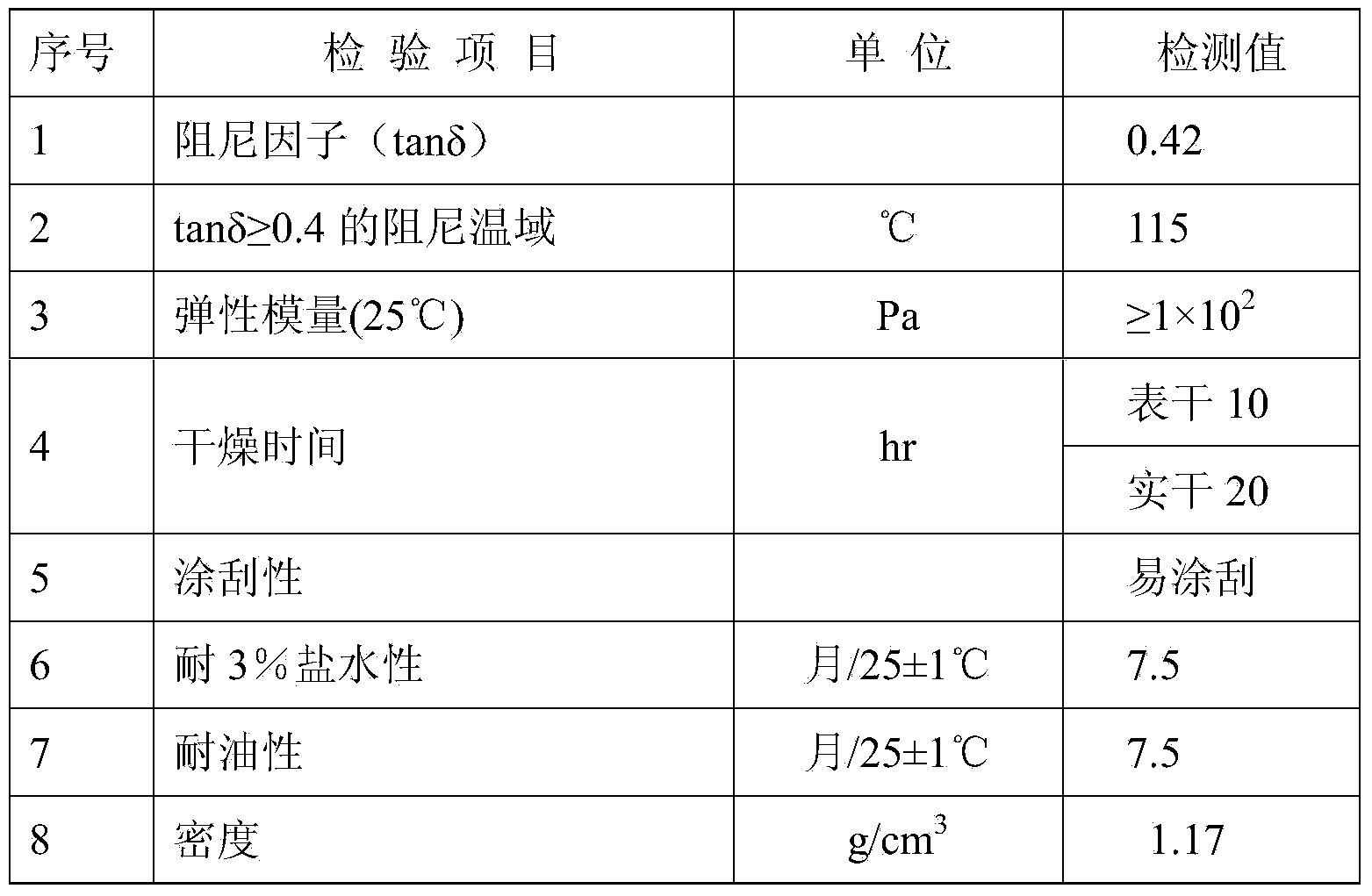

Examples

Embodiment 1

[0028] The damping paste provided in this example is prepared by mixing component A and component B, wherein the preparation method of component A is as follows: weigh polyether 2000, polyether 3050 and TDI, each material and its composition in the component The mass percentage in A is: polyether 2000 41.2% polyether 3050 41.2% TDI 17.6%, add polyether 2000, polyether 3050 and TDI in a clean water-bath reactor, raise the temperature in the reactor to 60°C, Then heat-retain and react at this temperature for 3 hours until the NCO value in the reactor is less than or equal to 5.7%, and discharge to obtain component A;

[0029] The preparation method of component B is as follows: (1), first weigh each component according to the mass percentage of each component, and each substance and its mass percentage in component B are:

[0030] Hydrated alumina 37.5% Mica powder 37.5%

[0031] Silica 5% Carbon Black 5% Silicone Oil 1%

[0032] Ethylene Glycol 1% Dibutyl Ester 10% Moka 4%. ...

Embodiment 2

[0041] The damping paste provided in this example is prepared by mixing component A and component B, wherein the preparation method of component A is as follows: weigh polyether 2000, polyether 3050 and TDI, each material and its composition in the component The mass percent in A is: polyether 2000 40% polyether 3050 40% TDI 20%, add polyether 2000, polyether 3050 and TDI in a clean water bath reactor, the temperature in the reactor is raised to 60 ° C, Then heat-retain and react at this temperature for 3 hours until the NCO value in the reactor is less than or equal to 5.7%, and discharge to obtain component A;

[0042] The preparation method of component B is as follows: (1), first weigh each component according to the mass percentage of each component, and each substance and its mass percentage in component B are:

[0043] Hydrated alumina 35% Mica powder 45%

[0044] Silica 4% Carbon Black 4% Silicone Oil 0.5%

[0045] Ethylene Glycol 0.5% Dibutyl Ester 8% Moka 3%.

[0...

Embodiment 3

[0051]The damping paste provided in this example is made by mixing and stirring component A and component B, wherein the preparation method of component A is as follows: weigh polyether 2000, polyether 3050 and TDI, each material and its component The mass percent in A is: polyether 2000 45% polyether 3050 40% TDI 15%, add polyether 2000, polyether 3050 and TDI in a clean water bath reactor, the temperature in the reactor is raised to 60 ° C, Then heat-retain and react at this temperature for 3 hours until the NCO value in the reactor is less than or equal to 5.7%, and discharge to obtain component A;

[0052] The preparation method of component B is as follows: (1), first weigh each component according to the mass percentage of each component, and each substance and its mass percentage in component B are:

[0053] Hydrated alumina 36% Mica powder 36%

[0054] Silica 6% Carbon Black 6% Silicone Oil 1%

[0055] Ethylene Glycol 1% Dibutyl Ester 9% Moka 5%.

[0056] After preh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com