Vacuum ion plating three-axis uniform speed continuous rotation coating device

A technology of vacuum ion plating and coating device, which is used in ion implantation plating, vacuum evaporation plating, sputtering plating, etc., can solve the problem that uniform rotation cannot be achieved, and the plated parts cannot be uniformly bombarded by ion beams, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

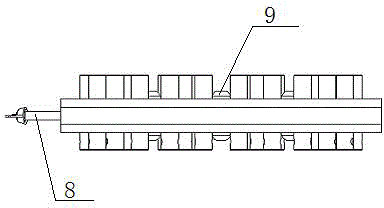

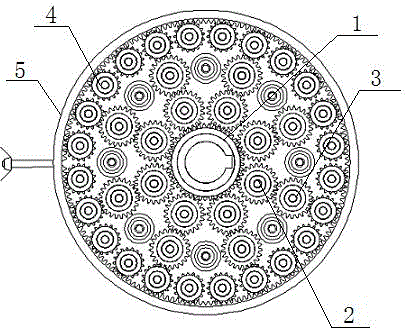

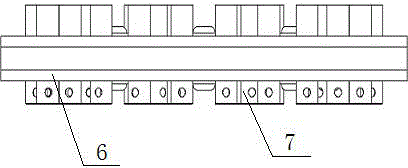

[0015] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the vacuum ion plating three-axis uniform-speed continuous-rotation coating device is a constant-speed continuous-rotation device in which the sun gear and the ring gear jointly output the torque required for rotation and equidistantly multiplies the rotation axis, including the sun gear 1 and the inner planetary gear 2 , Transition planetary gear 3, outer planetary gear 4, ring gear 5, ring gear stop rod 8, planet carrier 6 and planet carrier fixing device 9, sun gear 1 is installed on the center position of planet carrier 6,. The inner planetary gear 2, the transitional planetary gear 3 and the outer planetary gear 4 are radially arranged between the sun gear 1 and the ring gear 5, the ring gear limit rod 8 is fixed on the ring gear 5, and the planet carrier 6 passes through the planet carrier The fixing device 9 is fixed, and the force transmission of the sun gear 1 is driven by the torque transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com