Filament POY (Pre-Oriented Yarn) drafting and winding device

A winding device, filament technology, applied in rayon filament physiotherapy, bundling of newly ejected filaments, textiles and papermaking, etc. The effect of reducing yarn breakage, improving yarn quality and reducing occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention and are not intended to limit the scope of the invention.

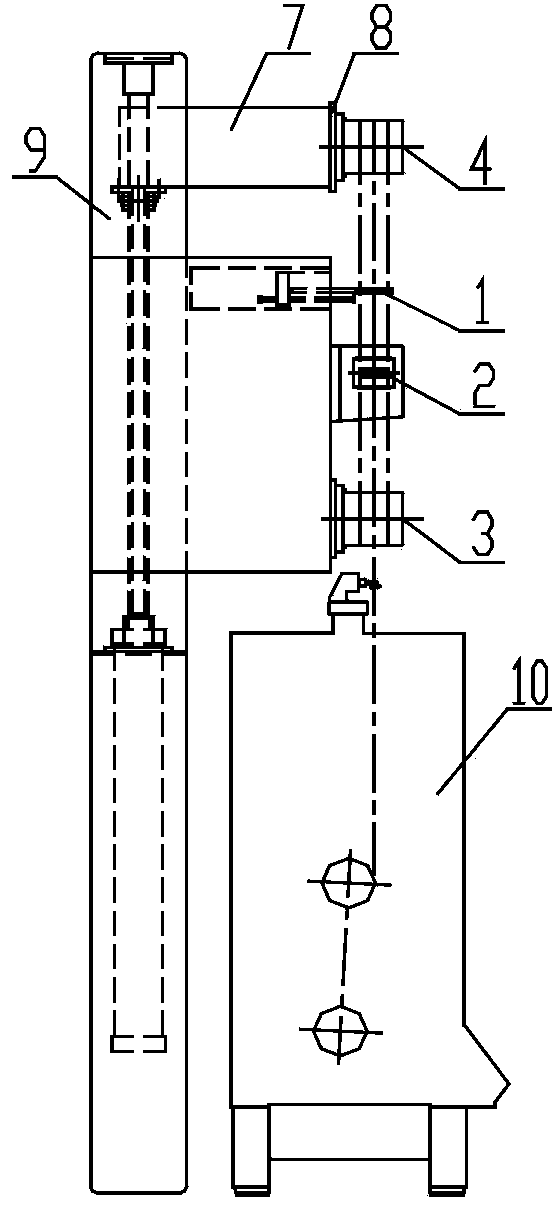

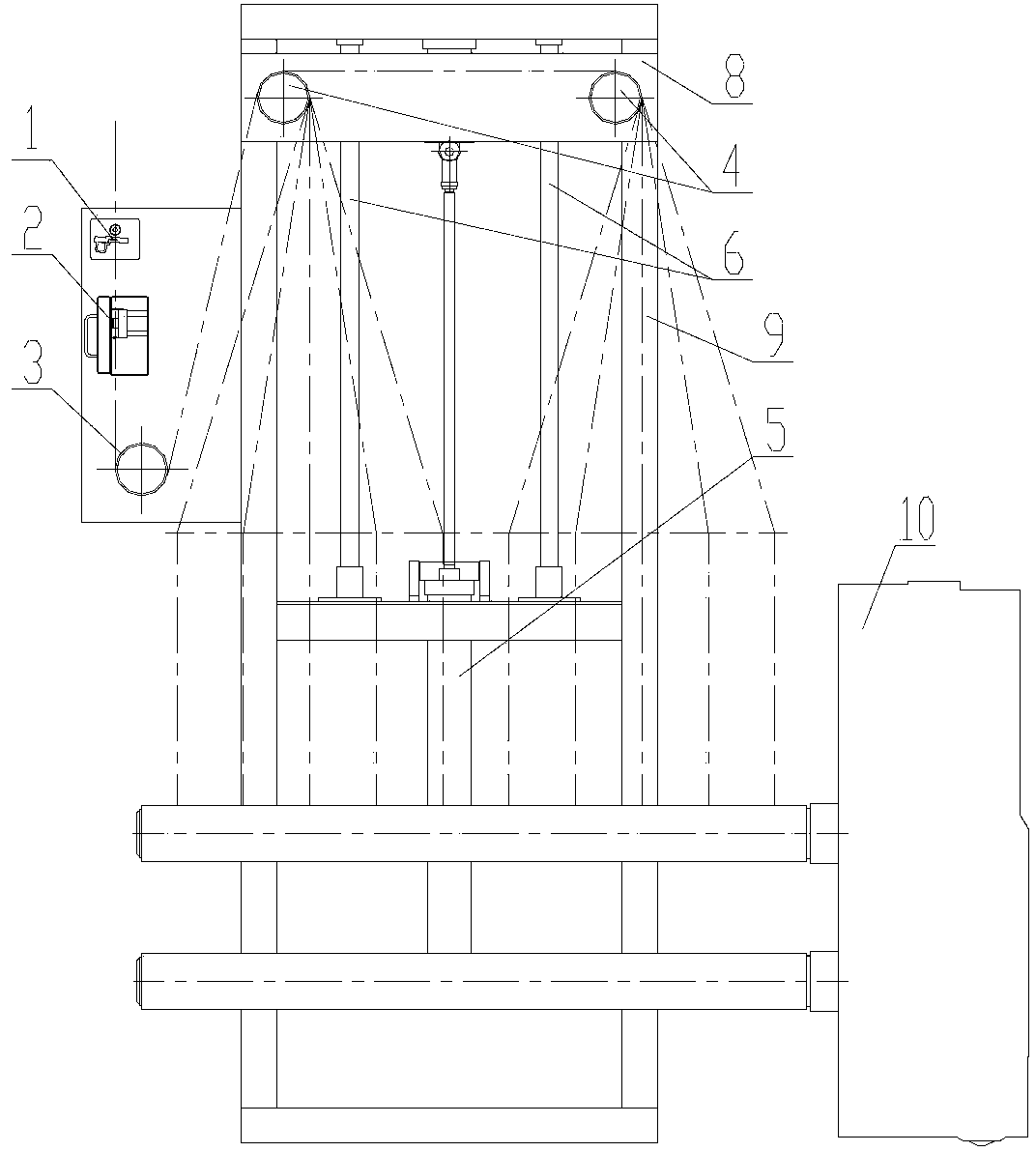

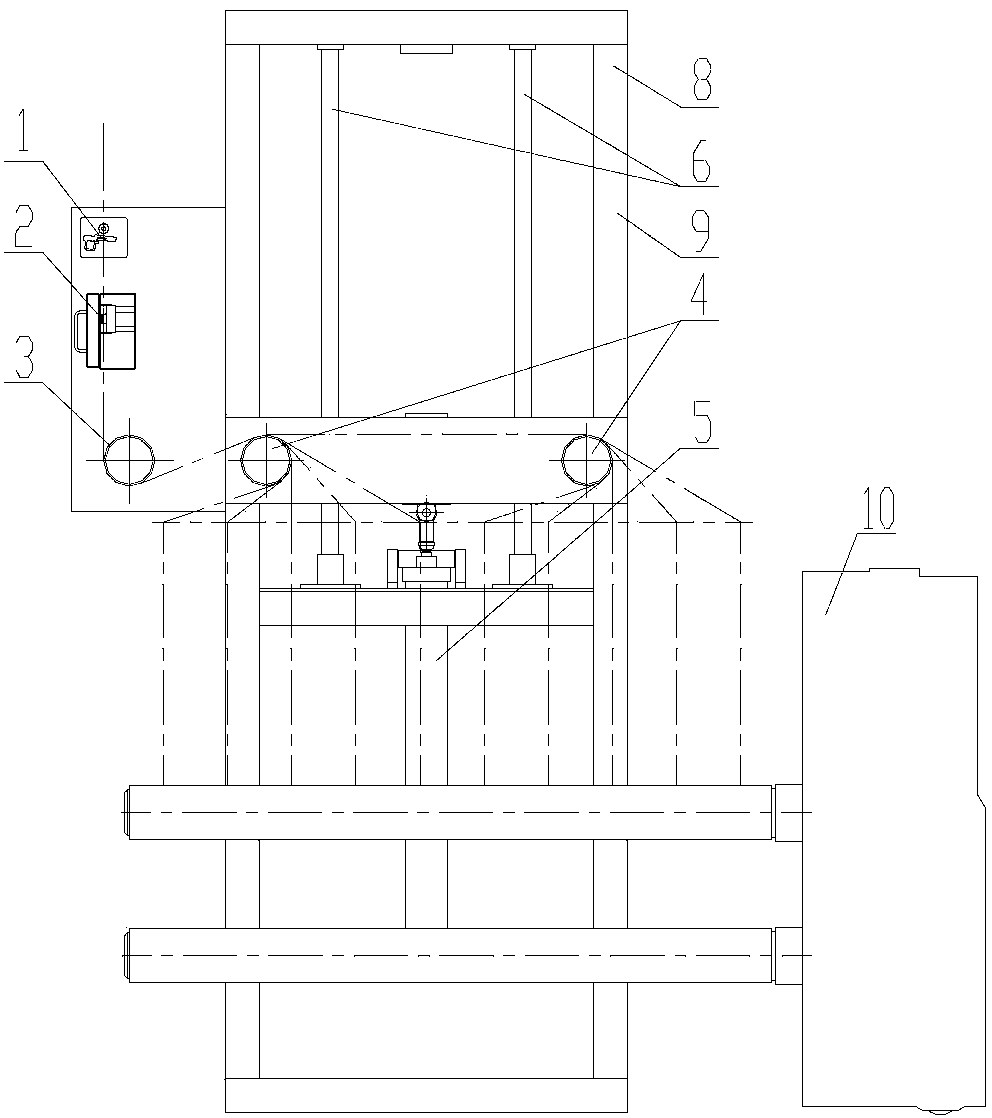

[0026] see figure 1 , figure 2 and image 3 , the present invention provides a POY filament drafting and winding device, comprising a cutting and suction device 1, a pre-netting device 2, a first godet 3, a second godet 4, a lifting mechanism, a lifting seat 7, a frame 9 and winding head 10. The lifting mechanism can be a mechanism capable of lifting such as a cylinder or a lead screw. In this embodiment, preferably, the lifting mechanism adopts the cylinder 5, which can quickly and stably realize lifting.

[0027] The yarn cutting and aspirating device 1 , the pre-netting device 2 , and the first wire godet 3 are installed on the left side of the frame 9 parallel to the operation surface in sequence accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com