Elevated net box based on composite drum-type foundation of offshore wind turbine

A technology of cylindrical foundation and offshore wind turbine, which is applied to the installation/support of wind turbine configuration, wind power generation, engine components, etc. It can solve the problems of breeding loss, large cost, and damage to cages, so as to increase income and reduce infrastructure costs. , the effect of stabilizing the swimming space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

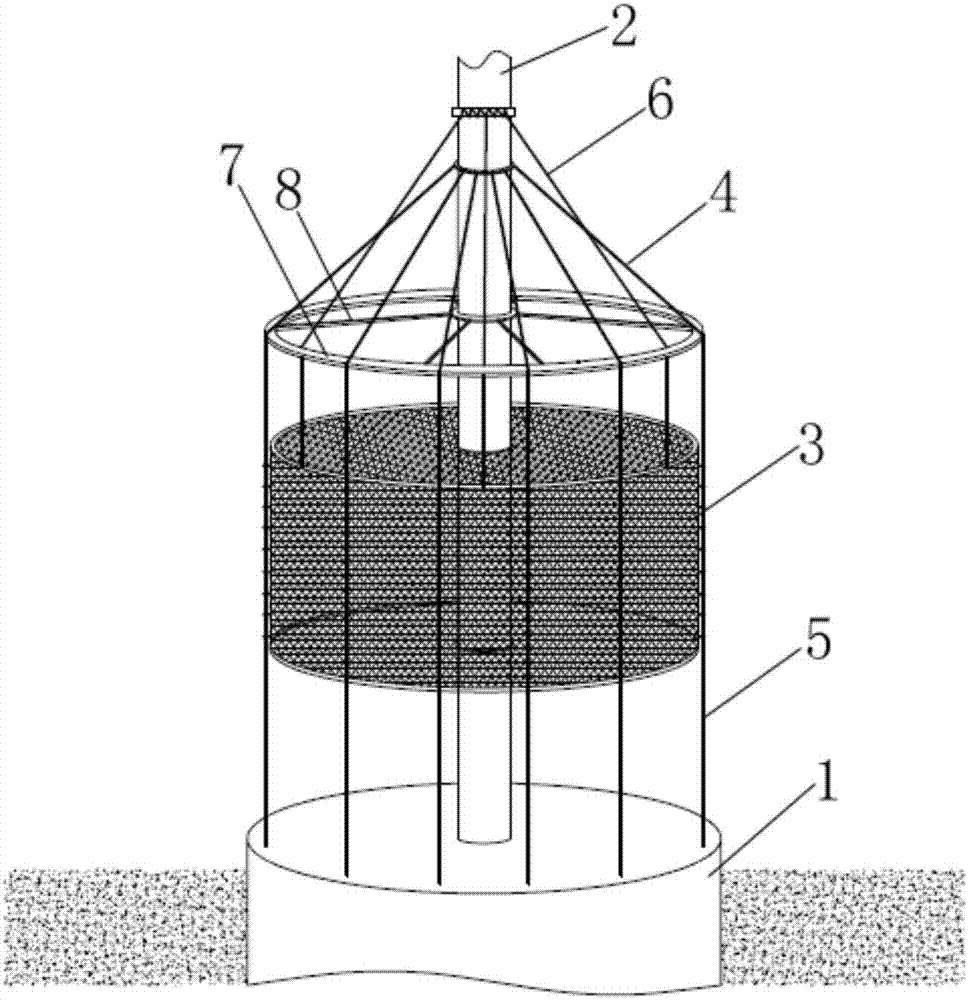

[0021] Such as figure 1 The shown lifting net cage based on the composite cylindrical foundation of offshore wind turbines includes a cylindrical composite cylindrical foundation abutment 1 , a wind turbine base column 2 , a breeding cage 3 and a support frame 7 .

[0022] The cylindrical composite cylindrical foundation abutment 1 is built on the seabed, and the wind power generator base column 2 is built on the cylindrical composite cylindrical foundation abutment 1 .

[0023] The supporting frame 7 is fixedly installed on the base column 2 of the wind power generator through the supporting fixture 8 . The support fixture 8 includes a fixed ring in the middle and support rods uniformly arranged along the circumferential direction. The fixed ring is fixed on the base column 2 of the wind power generator. The support rods are radial as a whole. fixed. The gravity of the support frame 7 is carried by 10 drag cables 4 above the support frame 7 , the lower ends of the drag cabl...

Embodiment 2

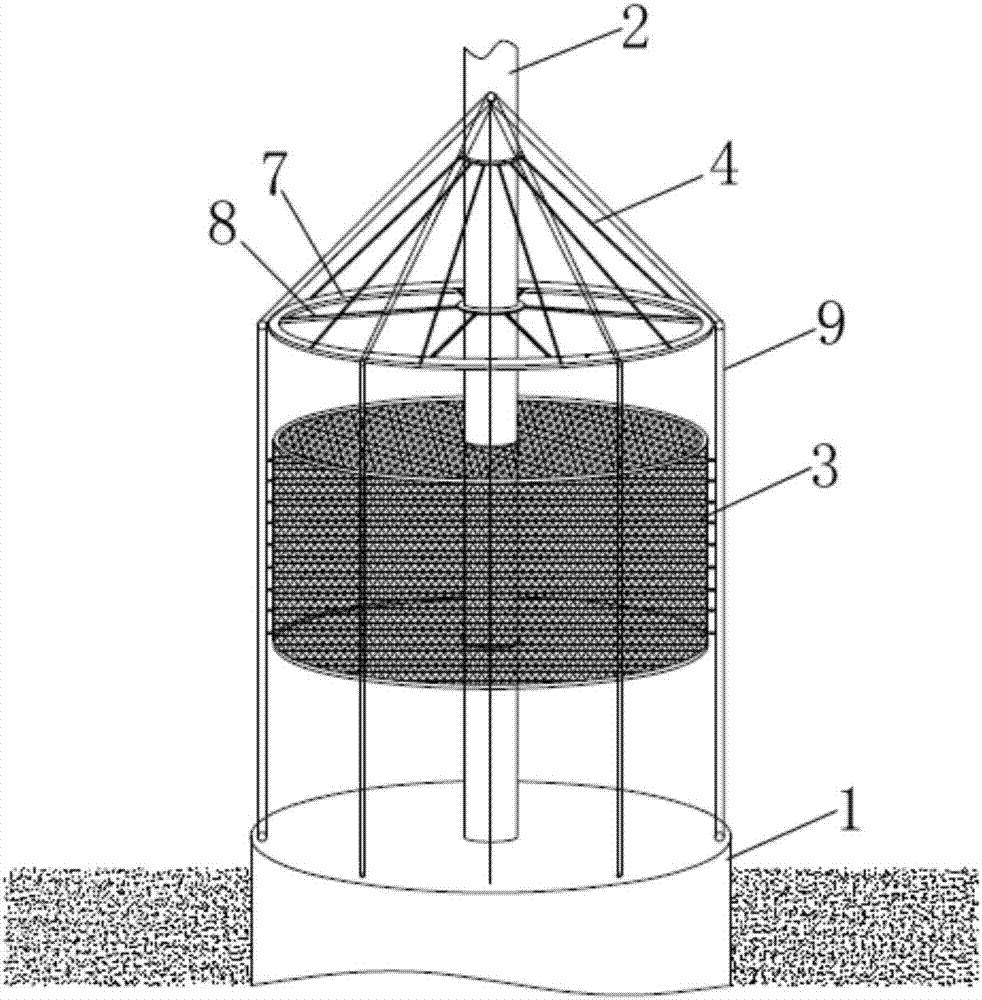

[0028] Such as figure 1 The shown lifting net cage based on the composite cylindrical foundation of offshore wind turbines includes a cylindrical composite cylindrical foundation abutment 1 , a wind turbine base column 2 , a breeding cage 3 and a support frame 7 .

[0029] The cylindrical composite cylindrical foundation abutment 1 is built on the seabed, and the wind power generator base column 2 is built on the cylindrical composite cylindrical foundation abutment 1 .

[0030] The supporting frame 7 is fixedly installed on the base column 2 of the wind power generator through the supporting fixture 8 . The support fixture 8 includes a fixed ring in the middle and support rods uniformly arranged along the circumferential direction. The fixed ring is fixed on the base column 2 of the wind power generator. The support rods are radial as a whole. fixed. The gravity of the support frame 7 is carried by 10 drag cables 4 above the support frame 7 , the lower ends of the drag cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com