Tension type sit-on-bottom net cage

A technology of sitting on the bottom and stretching, which is applied in fish farming, application, climate change adaptation, etc., can solve the problems of unsuitable fish farming, lack of supporting technology and facilities, poor anti-wave and anti-current capabilities, etc., and achieve reduction damage, prolong the service life, and expand the effect of farming operation window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

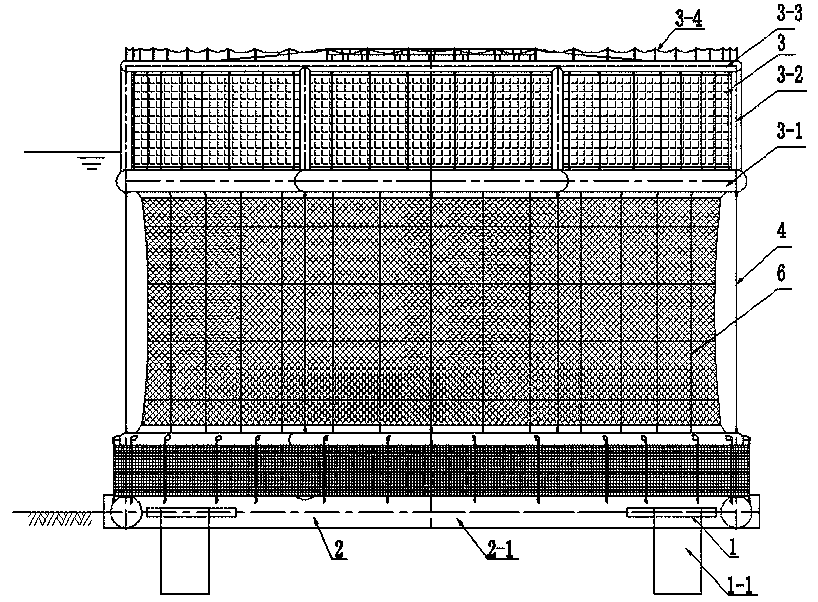

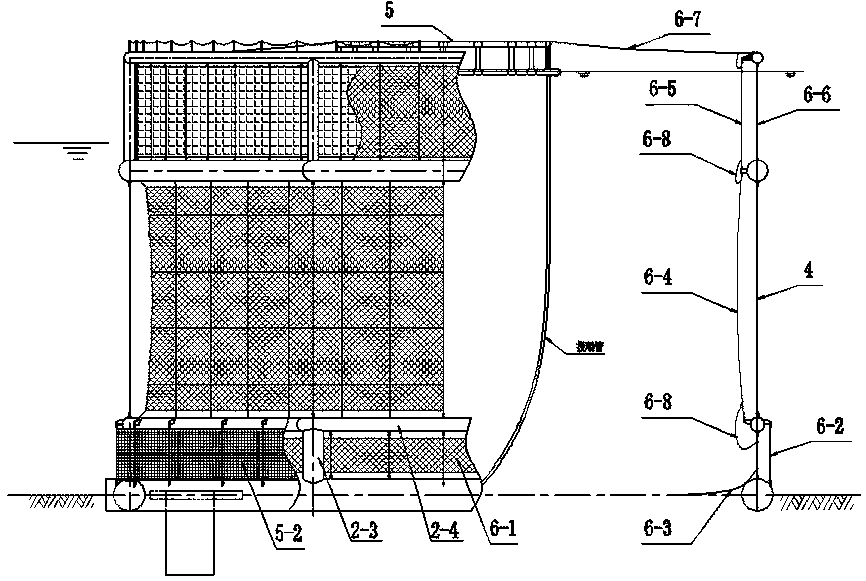

[0033] Attached below Figure 1-5 , the present invention is described in detail.

[0034] The cage system of the present invention is composed of an anti-slip pile foundation 1, a foundation frame 2, a tension floating frame 3, a tension cable system 4, a feeding floating frame 5 and a net body system 6.

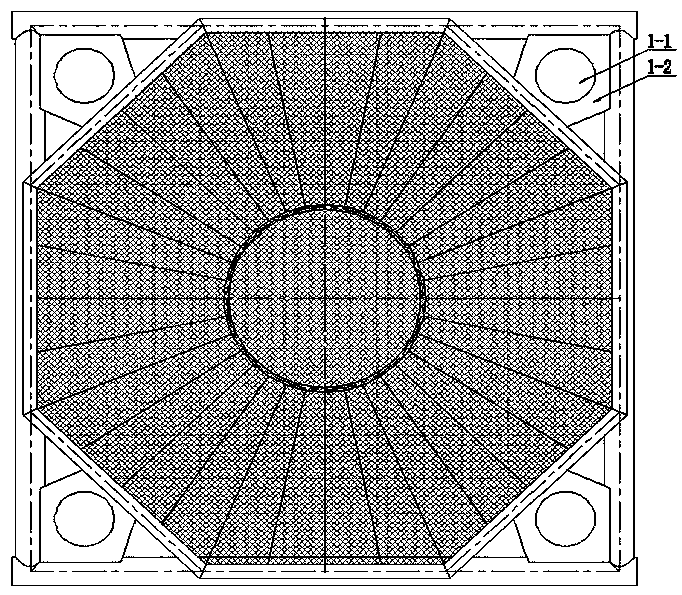

[0035] The anti-skid foundation 1 is a group of cylindrical foundations 1-1, which adopt the cylindrical foundation form as the anti-skid system of the net cage, and have the advantages of high reliability, convenient installation and removal, and reusable utilization of the net cage. The cylindrical foundation 1-1 is installed on the bottom of the basic frame 2 through the limiting structure 1-2, and the cylindrical foundation 1-1 and the limiting structure 1-2 can be arranged at each end corner of the basic frame 2.

[0036] The basic frame 2 is a frame structure with structural steel as the main material that can independently bear the load. The frame structure can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com