Thermomagnetic engine and thermomagnetic engine system

An engine, thermo-magnetic technology, applied in electrical components, machines/engines, mechanical equipment, etc., can solve problems such as reducing the amount of energy conversion, ignoring kinetic energy or potential energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

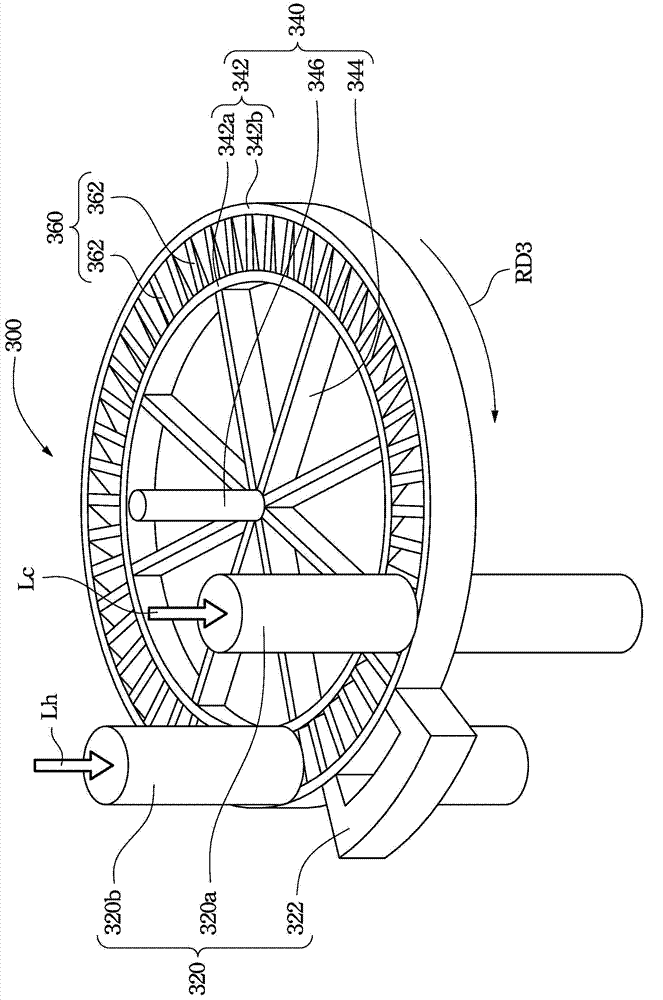

[0080] In the present invention, the rotating part of the thermomagnetic engine is provided with a fin structure. When the working fluid flows through the rotating part, the fin structure drives the rotating part to rotate in the direction of rotation based on the kinetic energy or potential energy of the working fluid flowing. In this way, the temperature difference and kinetic energy or potential energy of the working fluid can be more fully utilized to increase the overall energy conversion efficiency.

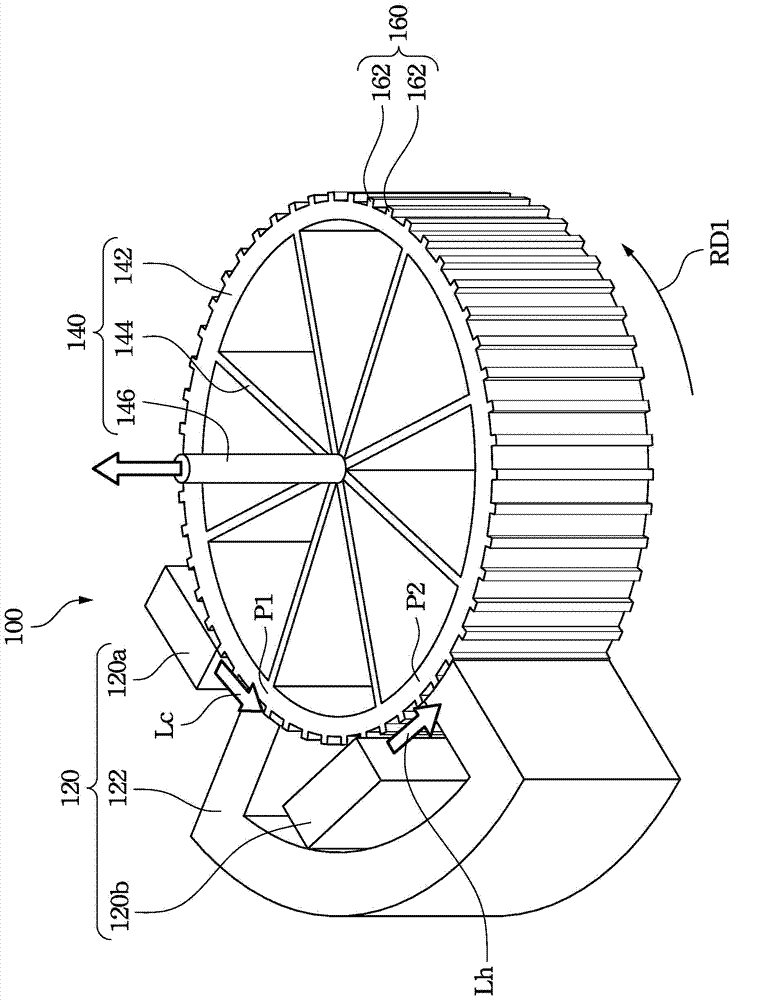

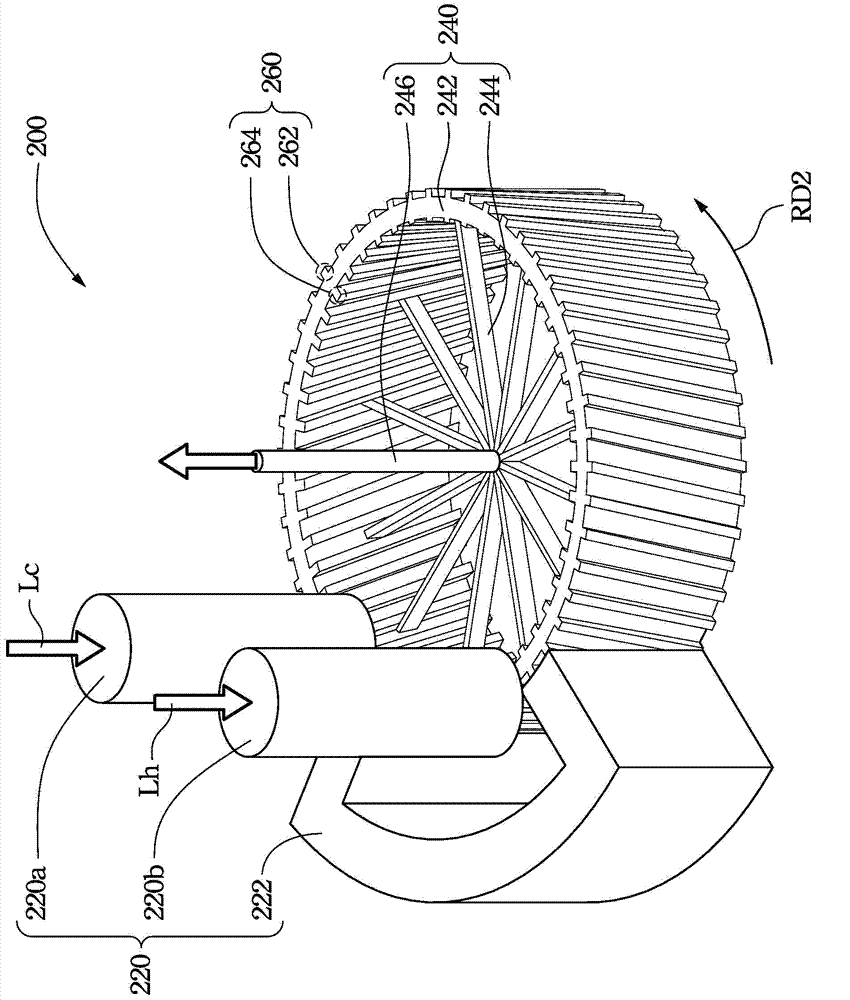

[0081] see figure 1 , figure 1 It is a schematic side view showing the internal main structure of a thermomagnetic engine 100 according to the first embodiment of the present invention. As shown in the figure, the thermomagnetic engine 100 includes a fixing member 120 (in this example, the fixing member 120 includes a low-temperature working fluid (Lc) feeding end 120a, a high-temperature working fluid (Lh) feeding end 120b, and a magnetic fixed yoke 122), Relatively rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com