Process for preparing arsenic-removing composite materials from red mud

A composite material and red mud technology, applied in the field of materials engineering, can solve the problems of unfavorable promotion and application in the field of arsenic removal, high cost of preparation of nano-iron particles, and reduction of reaction specific surface area, so as to facilitate large-scale production and improve governance efficiency , Reduce the effect of red mud pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

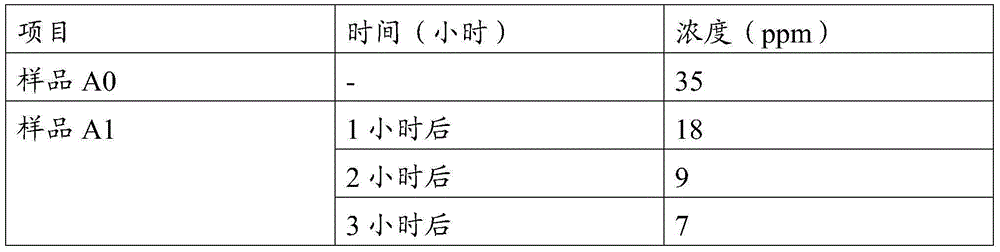

Examples

Embodiment 1

[0023] Pickling: Take out 10ml of 37% hydrochloric acid, add 110ml of distilled water to dilute to a 3% solution (1 mol / L). Take out 10 grams of red mud slurry, add 60 ml of 3% dilute hydrochloric acid solution, add distilled water to 500 ml, heat to 90 degrees, stir thoroughly for 30 minutes and then cool to room temperature. The red mud solids and filtrate were separated by filtration. The separated filtrate was put into a 500 ml container and cooled to room temperature for use. The separated red mud solids were washed three times with distilled water and filtered for later use.

[0024] Reduction: take out 3.8 g of sodium borohydride, add 100 ml of distilled water to dilute to a solution of 38 g / L (1 mol / L). Add 50 milliliters of 1 mol / liter sodium borohydride solution to reduce the iron in the solid to the separated red mud solid for use in the previous step. After filtering, the solid and the liquid were separated, and the separated solid was washed three times with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com