Dispensing technology

A dispensing process and dispensing technology, applied in mechanical equipment, connecting components, etc., can solve the problems of inapplicable plane and curved surface or curved surface and curved surface, cumbersome measurement, error, accuracy, and strength, etc., to achieve easy operation and process. Convenient, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

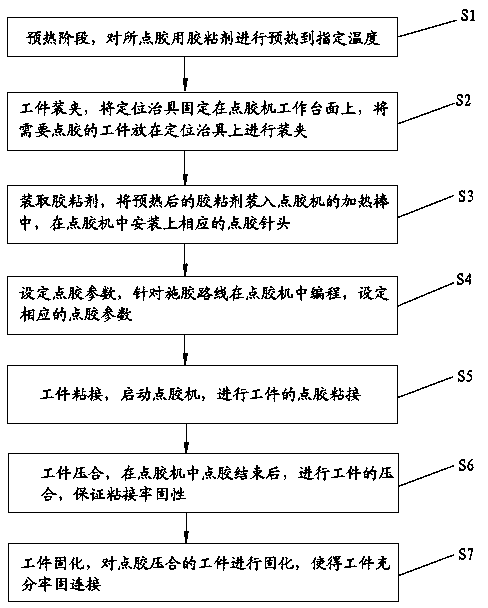

[0036] see figure 1 , a block diagram of the dispensing process flow provided by the present invention, including the following steps:

[0037] S1. In the preheating stage, the adhesive used for dispensing is preheated to the specified temperature;

[0038] S2, workpiece clamping, fix the positioning fixture on the working table of the glue dispenser, place the workpiece to be dispensed on the positioning fixture for clamping;

[0039] S3, load and take the adhesive, put the preheated adhesive into the heating rod of the dispenser, and install the corresponding dispensing needle in the dispenser;

[0040] S4. Set the dispensing parameters, program in the dispensing machine according to the glue sizing route, and set the corresponding dispensing parameters;

[0041] S5, workpiece bonding, start the dispensing machine, and carry out the dispensing and bonding of the workpiece;

[0042] S6, workpiece pressing, after dispensing in the glue dispenser, carry out the pressing of t...

Embodiment 2

[0053] S1. In the preheating stage, the adhesive used for dispensing is preheated to the specified temperature;

[0054] S2, workpiece clamping, fix the positioning fixture on the working table of the glue dispenser, place the workpiece to be dispensed on the positioning fixture for clamping;

[0055] S3, load and take the adhesive, put the preheated adhesive into the heating rod of the dispenser, and install the corresponding dispensing needle in the dispenser;

[0056] S4. Set the dispensing parameters, program in the dispensing machine according to the glue sizing route, and set the corresponding dispensing parameters;

[0057] S5, workpiece bonding, start the dispensing machine, and carry out the dispensing and bonding of the workpiece;

[0058] S6, workpiece pressing, after dispensing in the glue dispenser, carry out the pressing of the workpiece to ensure the firmness of the bonding;

[0059] S7. The workpiece is solidified, and the glued and pressed workpiece is solid...

Embodiment 3

[0069] S1. In the preheating stage, the adhesive used for dispensing is preheated to the specified temperature;

[0070] S2, workpiece clamping, fix the positioning fixture on the working table of the glue dispenser, place the workpiece to be dispensed on the positioning fixture for clamping;

[0071] S3, load and take the adhesive, put the preheated adhesive into the heating rod of the dispenser, and install the corresponding dispensing needle in the dispenser;

[0072] S4. Set the dispensing parameters, program in the dispensing machine according to the glue sizing route, and set the corresponding dispensing parameters;

[0073] S5, workpiece bonding, start the dispensing machine, and carry out the dispensing and bonding of the workpiece;

[0074] S6, workpiece pressing, after dispensing in the glue dispenser, carry out the pressing of the workpiece to ensure the firmness of the bonding;

[0075] S7. The workpiece is solidified, and the glued and pressed workpiece is solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com