Material mechanical property in-situ three-point bending test platform with adjustable test environment temperature

A technology of material mechanics and testing environment, applied in the direction of applying stable bending force to test the strength of materials, analyzing materials, strength characteristics, etc., can solve the problem of not considering the influence of temperature field on material properties, and not involving the in-situ microscopic imaging system Observation, not involved in the study of mechanical properties and other issues, to achieve the effect of compact structure, simple structure and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

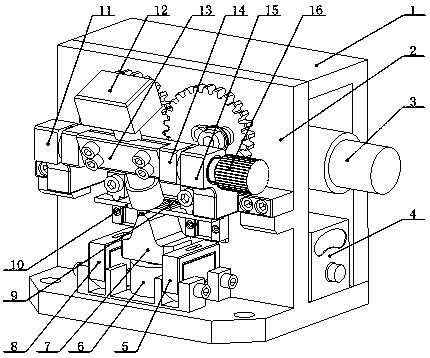

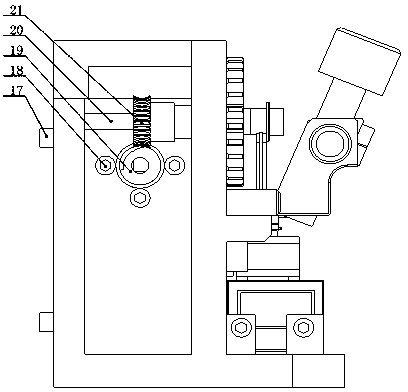

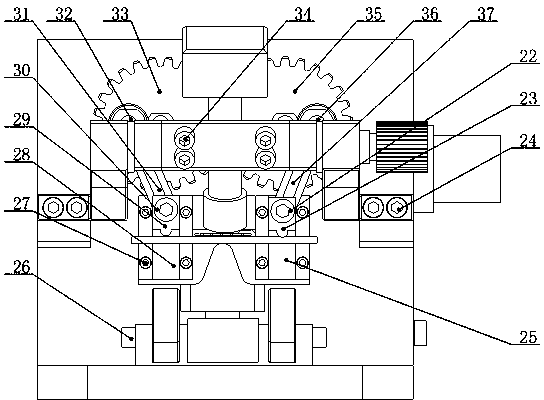

[0026] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0027] see Figure 1 to Figure 4 As shown, the in-situ three-point bending test platform for material mechanical properties with adjustable test environment temperature of the present invention includes a precision drive transmission unit, a detection unit, an imaging system unit, a temperature field control unit, and an auxiliary support unit. In-situ real-time dynamic observation of microstructure morphology, lattice changes, crack initiation and expansion under the action of electric field;

[0028] The precision drive transmission unit is composed of a DC motor 3, a shaft 20, a worm 19 and a worm wheel 21, wherein the DC motor 3 is fastened on the frame 2 by screws II 18, the output shaft of the motor 3 is fixedly connected with the worm 19, and the worm wheel 21 decelerates and outputs the power to the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com