Ammonium-nitrate-type explosive explosion method and apparatus based on shock-wave dynamic mixing

A dynamic mixing and shock wave technology, applied in the direction of explosives, material explosiveness, etc., can solve the problems that the reactants cannot fully react and cannot truly simulate the reaction process of new energetic materials, etc., and achieves low price, fast response, and reduces the possibility of coagulation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

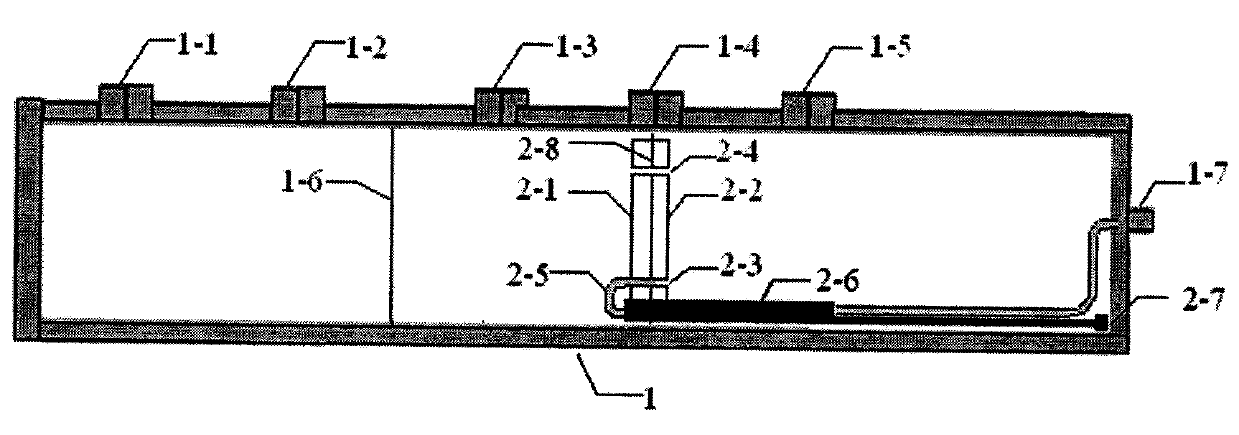

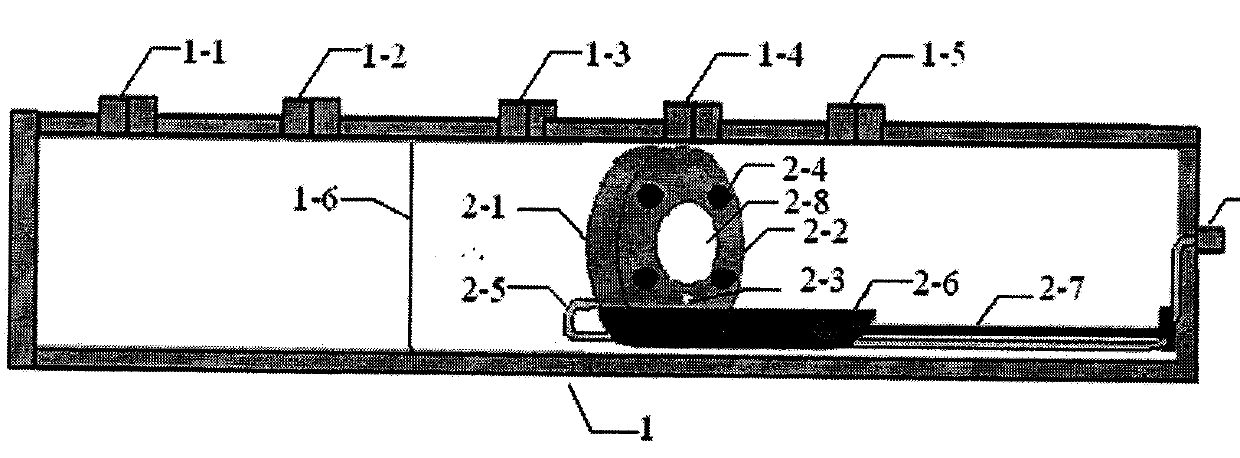

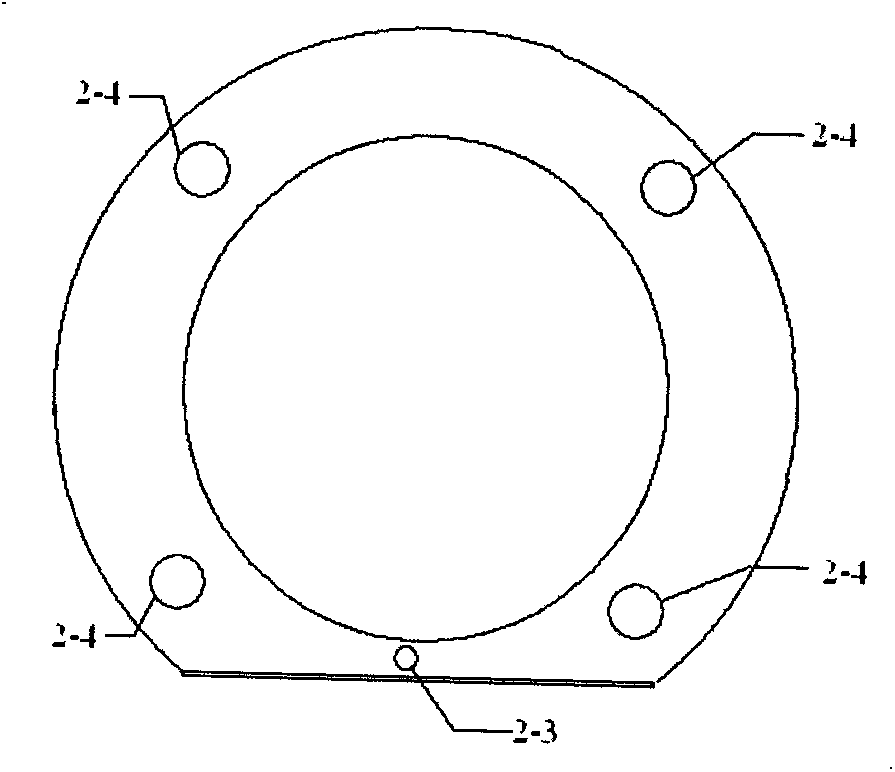

[0026] Such as figure 1 As shown, a new type of ammonium nitrate explosive explosion device based on the shock wave dynamic mixing method, including a shock tube 1 and a sample fixing device 2; wherein the shock tube 1 includes an ignition device 1-1, a driving section gas filling port 1 -2. Inflatable port 1-3 in the experimental section, first pressure sensor 1-4, second pressure sensor 1-5, polyethylene film 1-6, signal optical fiber outlet 1-7; sample fixing device 2 includes a fixed copper circle Ring 2-1, movable copper ring 2-2, optical fiber observation port 2-3, screw port 2-4, signal optical fiber protected by high temperature tube 2-5, ring base 2-6, support rod 2-7, Experimental powder bags 2-8.

[0027] In the sample fixing device, the fixed copper ring 2-1 is fixed on the ring base 2-6; the movable copper ring 2-2 can be removed after each test; two cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com