Recyclable cylindrical fiber glass gas blaster and manufacturing method thereof

A glass fiber, cylindrical technology, used in chemical instruments and methods, blasting cylinders, glass/slag layered products, etc., can solve problems such as high failure rate, difficult maintenance, air leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

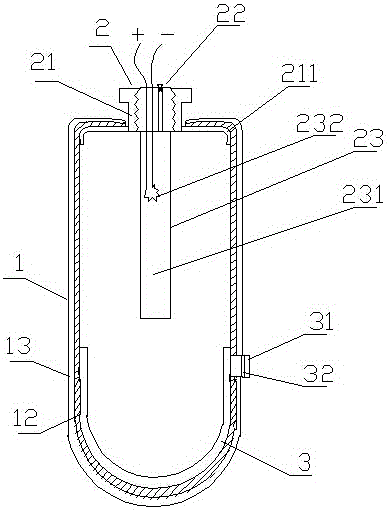

Embodiment 1

[0097] Example 1 as figure 1 As shown, a reusable cylindrical fiberglass gas blaster includes an energy storage device 1 and an inflatable detonation device 2, the energy storage device 1 is equipped with an inflatable detonation device 2 at one end, and the other end is sealed or integrally formed; The energy device 1 is made of solidified glass fiber material. The energy storage device 1 is cylindrical; Window 31, the energy-dissipating window 31 is sealed and installed with a constant-pressure burst disc 32, and the energy-dissipating inner cover 3 is made of metal.

[0098] As a further specific description of the above implementation, the energy storage device 1 has a two-layer structure, and the energy storage device 1 includes a mesh layer 12 and a hardened layer 13 distributed from the inside to the outside.

[0099] As a further specific description of the above implementation, the inflatable detonating device 2 includes a sealing base 21 , and an inflating mechanism...

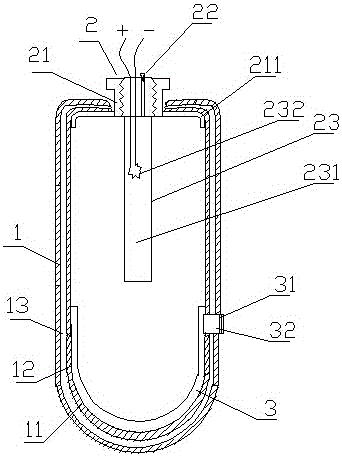

Embodiment 2

[0113] Embodiment two: the difference with embodiment one is: (such as figure 2 As shown) the energy storage device (1) has a three-layer structure, which consists of a base layer (11), a mesh layer (12) and a hardened layer (13) from inside to outside; the mesh layer (12) is glass Fiber material, the hardened layer (13) is made of epoxy resin glue material, and the base layer (11) is made of polyethylene material.

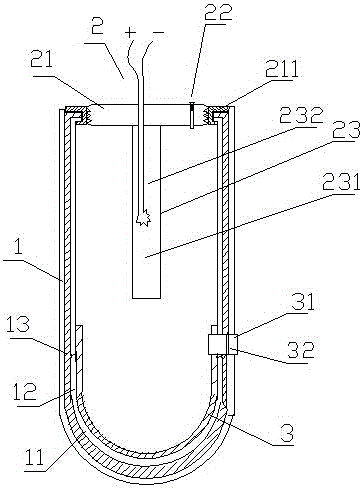

Embodiment 3

[0114] Embodiment three: the difference with embodiment two is: (such as image 3 As shown), the threaded structure in the middle of the sealing base 21 is inwardly recessed; this structure is convenient for transportation and saves the overall volume, and at the same time, it is convenient for protecting the inflatable detonator 2 from being hit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com