Method for adjusting the position of a supporting element in a particle beam device

A technology of support components and particle beams, which is applied to electrical components, irradiation devices, discharge tubes, etc., and can solve problems such as undesired movement of test benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

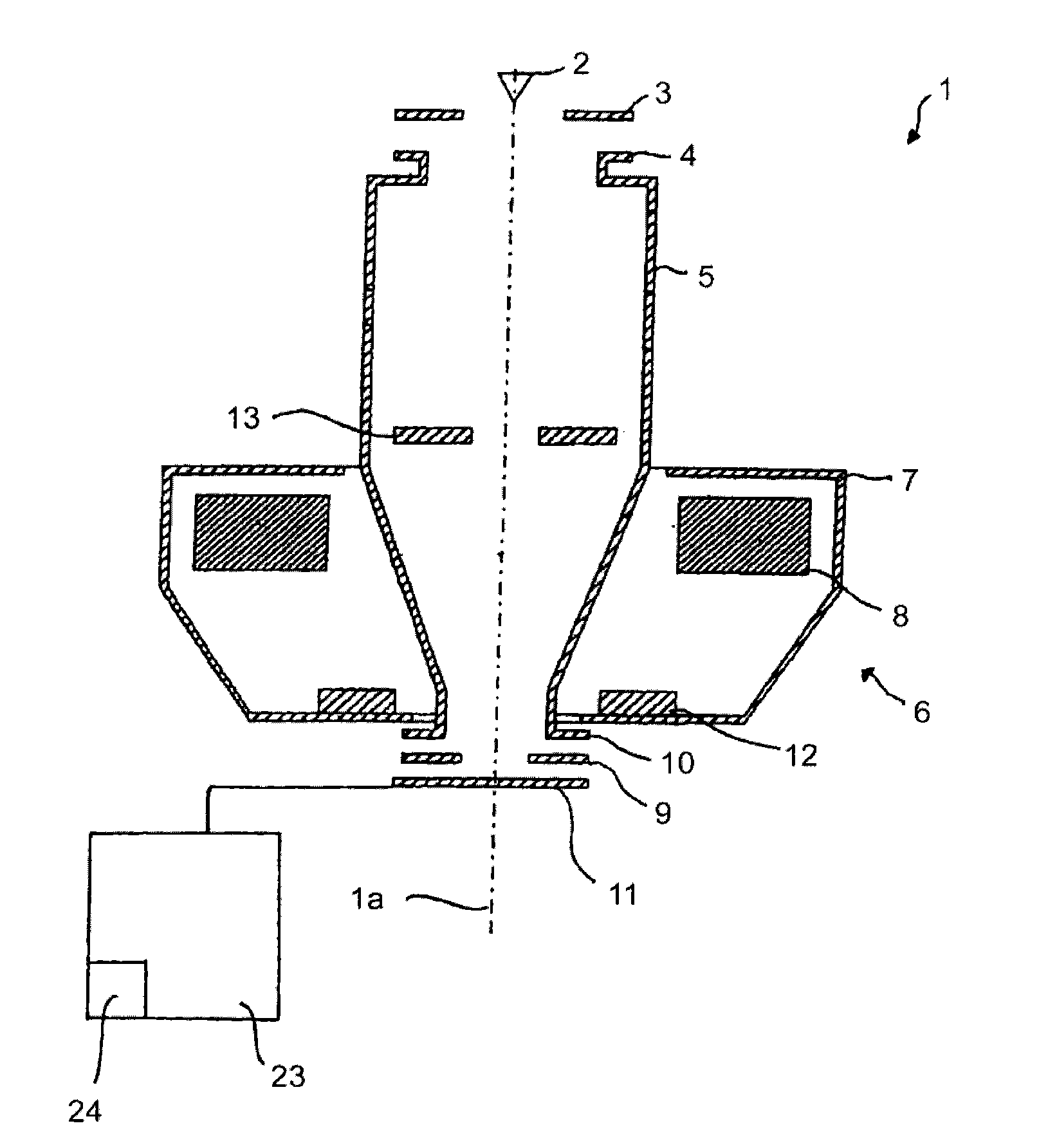

[0047] figure 1 A schematic diagram of a particle beam column 1 of a particle beam device is shown, which is designed as an electron beam column and essentially corresponds to an electron beam column of a scanning electron microscope. However, it is expressly pointed out here that the invention is not limited to scanning electron microscopes. Rather, the present invention can be used in various particle ray devices, particularly in ion beam devices.

[0048] The particle beam column 1 has an optical axis 1 a, a beam generator in the form of an electron source 2 (cathode), a extraction electrode 3 and an anode, which simultaneously form the end of a beam guide 5 . For example the electron source 2 is a thermal field emitter. Electrons emitted from the electron source 2 are accelerated towards the anode potential due to the potential difference between the electron source 2 and the anode 4 . This provides a particle beam in the form of an electron beam.

[0049]Furthermore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com