A curved bottom electrode thin film solar cell

An electrode film and solar cell technology, applied in the field of solar cells, can solve the problem of limited improvement in cell performance, and achieve the effects of improving collection capacity, improving conversion efficiency, and increasing light-receiving surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

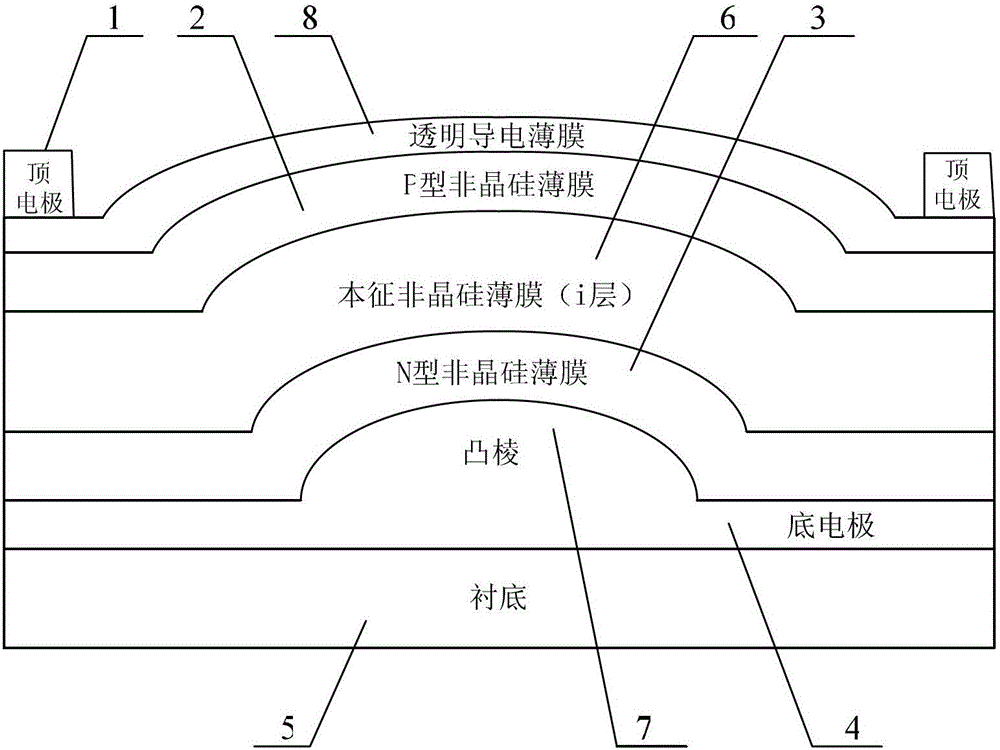

[0033] Product Example

[0034] Such as figure 2 Shown is the arc-shaped bottom electrode thin film solar cell of this embodiment, which includes a metal top electrode 1, a transparent conductive film 8, a P-type amorphous silicon film 2, an intrinsic amorphous silicon film 6, and an N-type thin film connected in sequence from top to bottom Amorphous silicon film 3, metal bottom electrode 4, substrate 5, the upper surface of metal bottom electrode 4 has a number of metal conductive ribs 7, and the upper surface of ribs 7 has an upward convex arc surface (in addition, the ribs can also use lower In this example, only one convex rib is drawn for illustration, but in fact there are many, such as N-type amorphous silicon film 3, intrinsic amorphous silicon film 6, The P-type amorphous silicon film 2 and the transparent conductive film 8 have s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com