Pipeline-type photobioreactor for scale culture of microalgae

A photobioreactor and pipeline technology, which is applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., can solve the difficulty of increasing the scale of culture volume, Reduce the light energy utilization rate of pipelines, limit the normal growth of microalgae and other problems, achieve the effect of ensuring uniformity of light, maximizing light energy utilization rate, and solving capacity limitation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

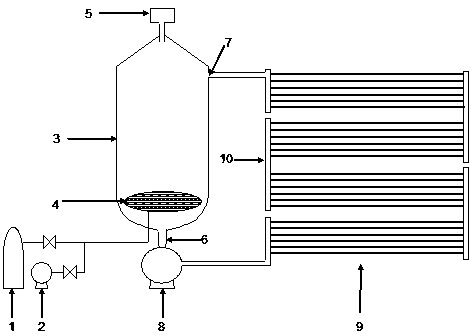

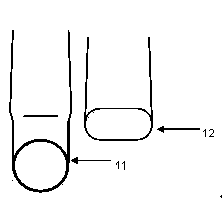

[0020] Such as figure 1 As shown, a pipe-type photobioreactor for large-scale cultivation of microalgae includes a gas exchange tank (3), a process pump (8), a CO2 supply system, and a photosynthesis pipeline array (9); the upper part of the gas exchange tank is equipped with There is an exhaust port (5) and a liquid outlet pipe (7), the lower part is provided with a liquid inlet pipe (6), and the liquid inlet pipe is connected to the photosynthesis pipeline array (9) through the process pump (8); the photosynthesis pipeline array (9) It is composed of 4 pipeline groups connected in series, and the pipeline group is formed by parallel connection of 3 linear pipelines made of high borosilicate glass. One end of the photosynthesis pipeline array (9) is connected to the liquid inlet pipe (6) , the other end is connected with the liquid outlet pipe (7); the CO2 supply system includes a CO2 cylinder (1), an air pump (2) and a CO2 aerator (4), a CO2 cylinder (1) and an air pump (2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com