A kind of waste water treatment agent and its preparation method and application

A wastewater treatment agent and flocculant technology, which is applied in the process of wastewater treatment, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of increased treatment cost, high suspended solids content, and difficulty in wastewater treatment, and achieves purification. Outstanding effect, enhanced flocculation, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

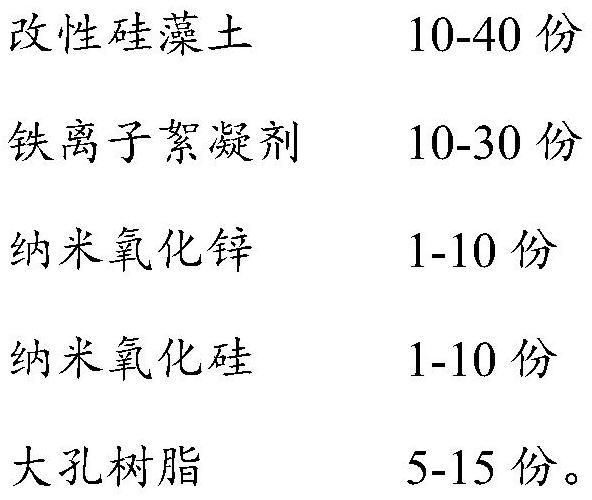

[0040] A wastewater treatment agent consisting of the following components:

[0041]

[0042]

[0043] The macroporous resin model is YKHCN-2 (purchased from Tianjin Yunkai Resin Technology Co., Ltd.), with a diameter of 0.3-1.25mm, and the iron ion flocculant is polyferric sulfate.

[0044] A preparation method for waste water treatment agent, comprising the following steps:

[0045] (1) Weigh 50g of graphene and 500g of diatomite, stir for 3h at a stirring rate of 250 rpm to make it fully mixed; then roast at a temperature of 650°C for 3h, and carry out crushing after cooling, and then Grinding and passing through an 80-mesh sieve to obtain graphene-modified diatomite;

[0046] (2) Then disperse 80g of polyacrylamide in water, add the graphene-modified diatomite prepared in step (1), stir for 3h at a stirring rate of 300 rpm, make it fully mixed; then stand 5h, dried at 60°C for 3 hours to obtain modified diatomite.

[0047] (3) Take 200g modified diatomite, 30g nan...

Embodiment 2

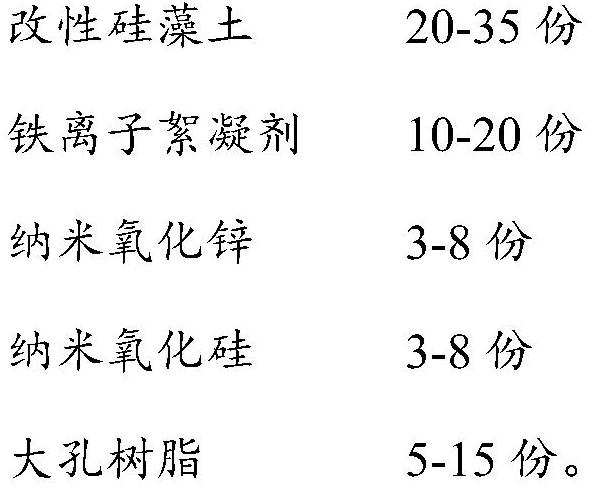

[0049] A wastewater treatment agent consisting of the following components:

[0050]

[0051] The type of macroporous resin is YKHCN-2, the diameter is 0.3-1.25mm, and the iron ion flocculant is polysilicate ferric chloride.

[0052] A preparation method for waste water treatment agent, comprising the following steps:

[0053] (1) Weigh 50g of graphene and 500g of diatomite, stir for 3h at a stirring rate of 250 rpm to make it fully mixed; then roast at a temperature of 650°C for 3h, and carry out crushing after cooling, and then Grinding and passing through an 80-mesh sieve to obtain graphene-modified diatomite;

[0054] (2) Then disperse 80g of polyacrylamide in water, add the graphene-modified diatomite prepared in step (1), stir for 3h at a stirring rate of 300 rpm, make it fully mixed; then stand 5h, dried at 60°C for 3 hours to obtain modified diatomite.

[0055] (3) Get 280g of modified diatomite, 60g of nano-zinc oxide, 60g of nano-silicon oxide, stir for 2h at a s...

Embodiment 3

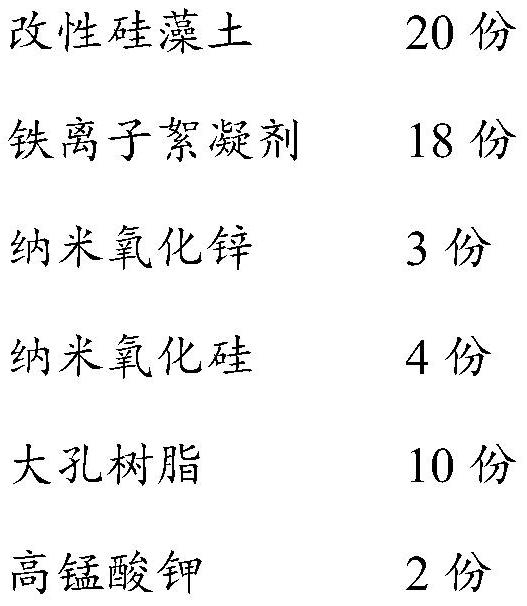

[0057] A wastewater treatment agent consisting of the following components:

[0058]

[0059] The type of macroporous resin is YKHCN-2, the diameter is 0.3-1.25mm, and the iron ion flocculant is polyferric sulfate.

[0060] A preparation method for waste water treatment agent, comprising the following steps:

[0061] (1) Weigh 50g of graphene and 500g of diatomite, stir for 3h at a stirring rate of 250 rpm to make it fully mixed; then roast at a temperature of 650°C for 3h, and carry out crushing after cooling, and then Grinding and passing through an 80-mesh sieve to obtain graphene-modified diatomite;

[0062] (2) Then disperse 80g of polyacrylamide in water, add the graphene-modified diatomite prepared in step (1), stir for 3h at a stirring rate of 300 rpm, make it fully mixed; then stand 5h, dried at 60°C for 3 hours to obtain modified diatomite.

[0063] (3) Get 350g of modified diatomite, 60g of nano-zinc oxide, 40g of nano-silicon oxide, stir for 2h at a stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com