Method used for increasing desulfuration denitration and demercuration efficiency

A technology for desulfurization, denitrification, mercury removal, and high efficiency, which is applied in the direction of separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of high investment costs for desulfurization, denitrification, and mercury removal devices, and the low efficiency of desulfurization, denitrification, and mercury removal. Reduce investment costs, improve efficiency, and ensure compliance with emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

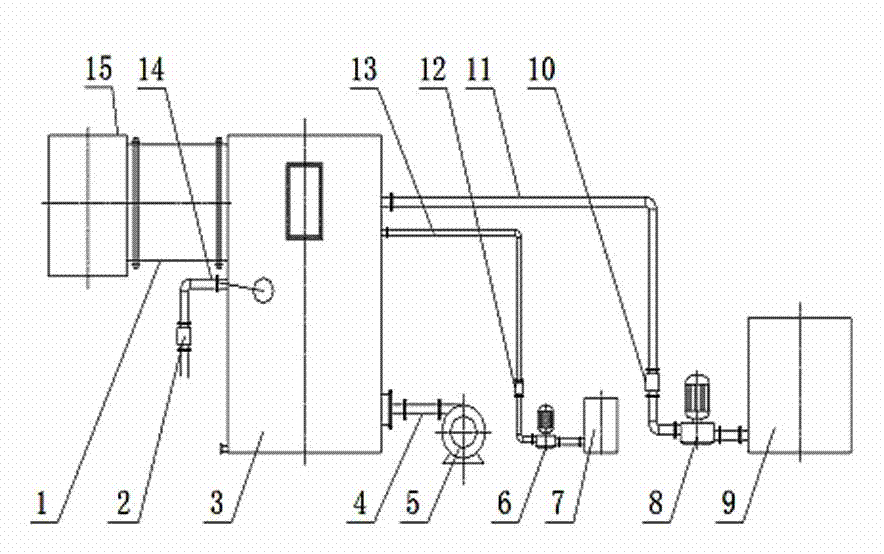

[0009] In the figure, the rear end of the main flue 15 is connected to the original flue gas treatment system 16, one end of the bypass flue 1 is connected to the front end of the main flue 15, and the other end is connected to the bubble generator 3; the slurry pump 8 passes through one end of the slurry pipe 11 It is connected to the slurry tank (pool) 9, and the other end is connected to the bubble generator 3. The slurry flow meter 10 is installed on the slurry pipe 11; the foaming agent pump 6 is connected to the foaming agent tank 7 through the foaming agent pipe 13 at one end, and the other end One end is connected with the bubble generator 3, and the foaming agent flow meter 12 is installed on the foaming agent pipe 13; the tap water flow meter 2 is installed on the tap water pipe 14, and the tap water pipe 12 is connected with the bubble generator 3; Tube 4 is connected to bubble generator 3 . The desulfurization, denitration and demercuration slurry in the slurry tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com