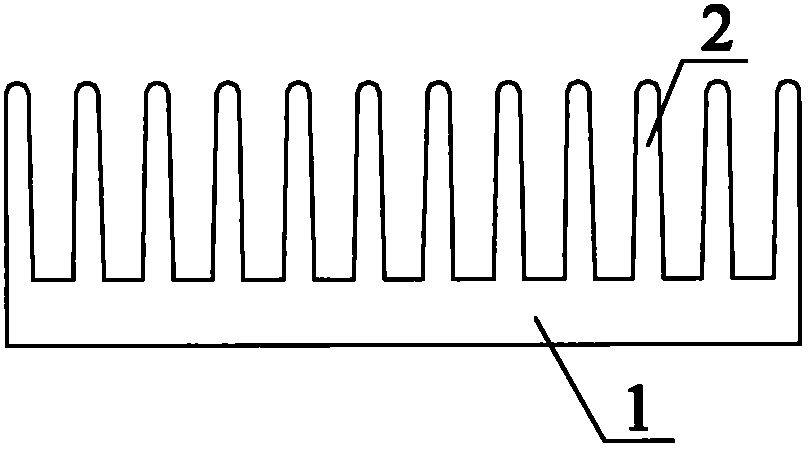

Combined heat dissipation module

A heat dissipation module and combined technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of high production and assembly costs, difficult to avoid position processing, troublesome radiator assembly, etc., to improve the heat dissipation effect, improve heat absorption and heat conduction Efficiency and stability, the effect of effective position avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

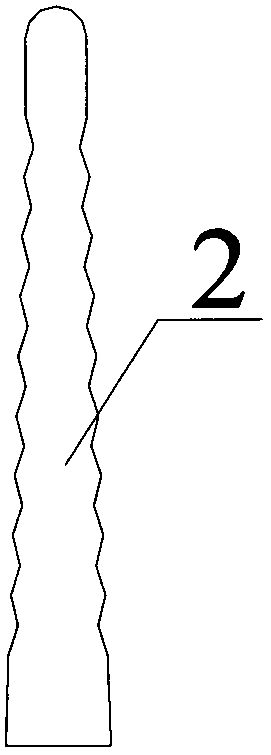

Embodiment 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the length of the main body of the connecting rod 3 is shorter than the side length of the base plate 1 . Therefore, the connecting rod 3 can be randomly inserted between the cooling fins on the substrate 1 shown.

Embodiment 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 2 is that: the surface of the connecting rod 3 is provided with a nickel-plated layer.

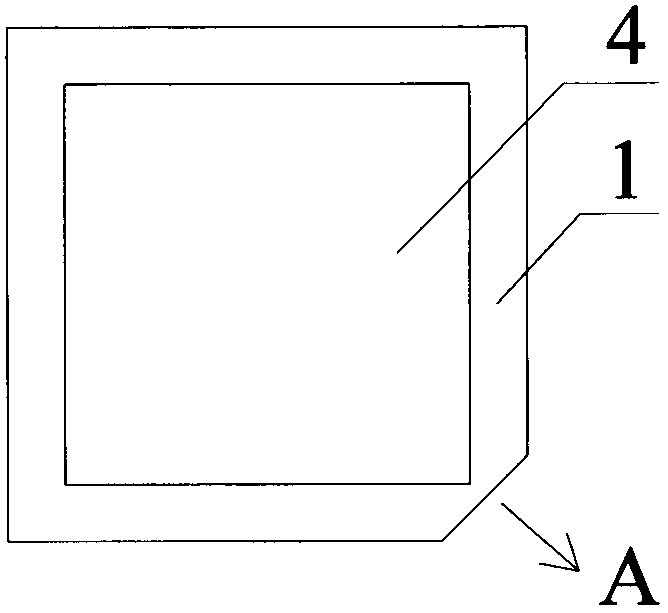

[0026] The invention utilizes a connecting rod to connect the combined heat dissipation module with the main body that needs heat dissipation, and can freely adjust the tightness of the hook according to the size of the main body that needs heat dissipation, which is convenient for use. In the combined heat dissipation module shown in the present invention, since the heat dissipation fins are uniformly arranged in a matrix, the substrate and the heat dissipation fins can be arbitrarily cut off according to actual needs or avoidance needs to meet the avoidance needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com