Curable composition and cured substance thereof

A curable composition and compound technology, applied in the direction of instruments, optical components, optics, etc., can solve the problems of coloring, loss of transparency, deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

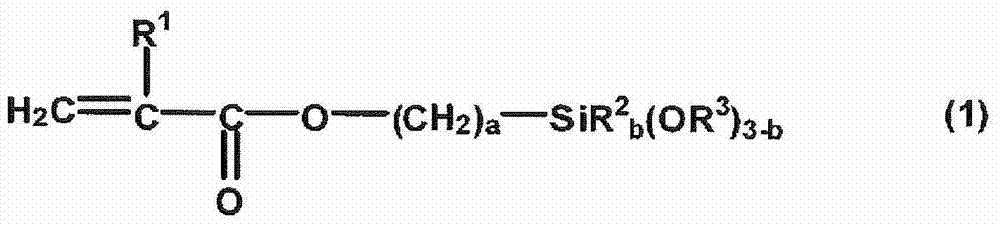

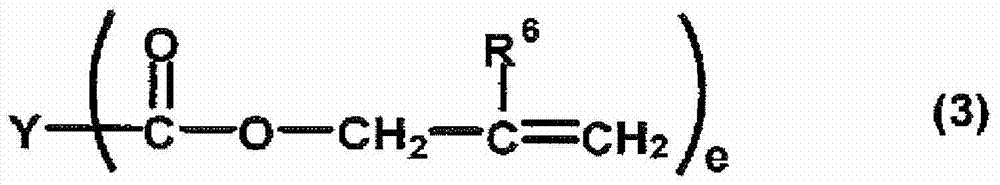

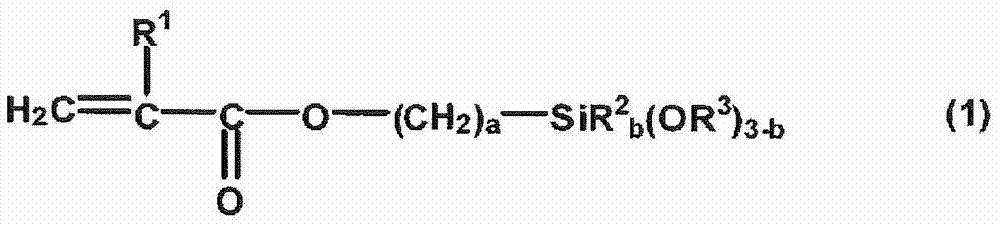

Method used

Image

Examples

Embodiment 1

[0255] (Example 1) Curable composition (A-1)

[0256] Isopropanol-dispersed colloidal silica (silica content: 30% by mass, average particle diameter: 10 to 20 nm, trade name Snowtec IPA-ST; manufactured by Nissan Chemical Industry Co., Ltd.) 100 Parts by mass, add 6.0 parts by mass of γ-methacryloxypropyltrimethoxysilane and 9.0 parts by mass of phenyltrimethoxysilane to the detachable flask, stir and mix, and then add 0.1825% by mass of 4.8 parts by mass of the HCl solution was stirred at 20° C. for 24 hours to surface-treat the silica fine particles.

[0257] Disappearance by hydrolysis of γ-methacryloxypropyltrimethoxysilane and phenyltrimethoxysilane was confirmed by gas chromatography (Agilent Co., Ltd. model 6850). Use a non-polar column DB-1 (manufactured by J&W Co., Ltd.), set the temperature at 50 to 300°C, heat up at a rate of 10°C / min, use helium as a carrier gas, and set the flow rate at 1.2cc / min. The chemical detector was determined by the internal standard met...

Embodiment 2

[0260] (Example 2) Curable composition (A-2)

[0261] Except that the amount of DAND used in Example 1 is changed to 10 parts by mass, the amount of A-BPEF used is changed to 21 parts by mass, and the amount of EA-F5503 used is changed to 19 parts by mass, the same operation is carried out as in Example 1, and A curable composition (A-2) was obtained.

Embodiment 3

[0262] (Example 3) Curable composition (A-3)

[0263] Except that the amount of DAND used in Example 1 was changed to 11 parts by mass, the amount of A-BPEF used was changed to 21 parts by mass, and EA-F5503 was not used, a curable composition was obtained in the same manner as in Example 1. (A-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com