Different-diameter guiding combined cutting tap or combined cutting cone

A compound cutting and tap technology, which is applied in thread cutting tools, thread cutting devices, metal processing equipment, etc., can solve the problems of scrapped workpieces, easy breakage of thread blades, and failure to play a guiding role.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

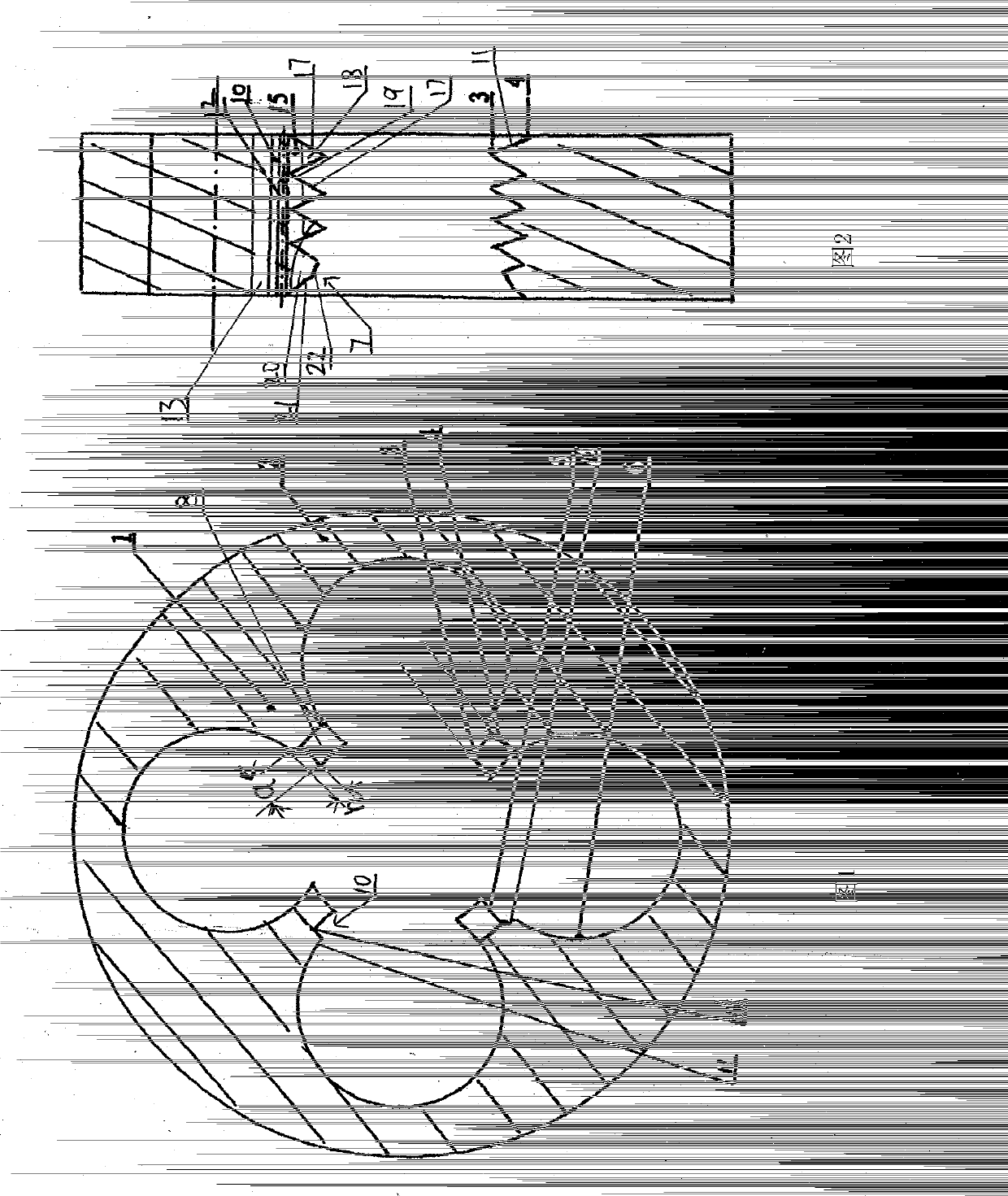

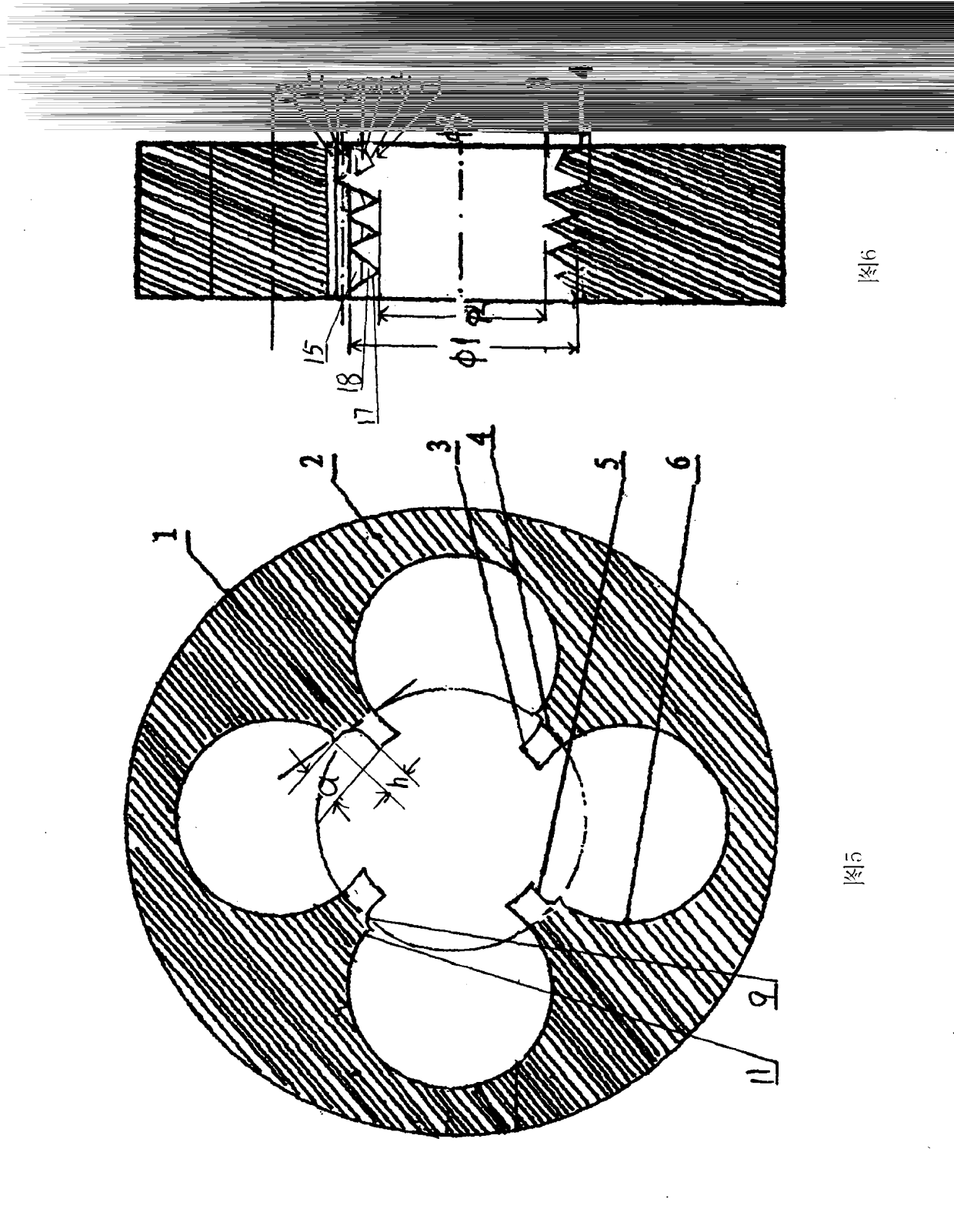

[0044] Such as figure 1 , figure 2 As shown, the split-diameter-guided compound cutting tap or compound cutting cone of the first embodiment includes a tap body 1 and a shell 2 connected or formed as one, and at least one thread body 1 is connected or integrated on the cone, or At least one spiral thread body 1, or at least one taper thread body 1, each thread body has a cutting edge surface 6 at the front of the split-diameter guide compound cutting tap or the axial front end of the compound cutting cone. The side chamfering 8 on the back side of the cutting edge surface 6 is the rear cutting surface 7, the outer surface of the cutting edge surface 6 is the side cutting surface 8, and the cutting edge surface 6 intersects with the rear cutting surface 7 to form a chamfering thread edge 9 , or the cutting edge surface 6 intersects with the side cutting surface 8 to form a cutting wire edge 11, and the diameter of the wire base 3 is The diameter of wire top 4 is It is char...

Embodiment approach 2

[0046] Such as image 3 , Figure 4 As shown, the split-diameter guiding compound cutting tap or compound cutting cone of the second embodiment, on the basis of the technical effect of the first embodiment, the present invention includes a tap body 1 and a casing 2, and the tap body 1 and the casing 2 connected or formed as one, or the taper body 1 and the shell 2, the taper body 1 and the shell 2 are connected or formed as one, at least one thread body 1 is connected or integrated on the tap or the cone, or at least A helical thread cutting body 1, or at least one tapered thread cutting body 1, each thread cutting body has a cutting edge surface 6 at the front end of the split-diameter-guided compound cutting tap or compound cutting cone, at the cutting entry point The surface of the cutting edge surface 6 back side chamfering 8 is the rear cutting surface 7, the surface on the outer side of the cutting edge surface 6 is the side cutting surface 8, and the cutting edge surfa...

Embodiment approach 3

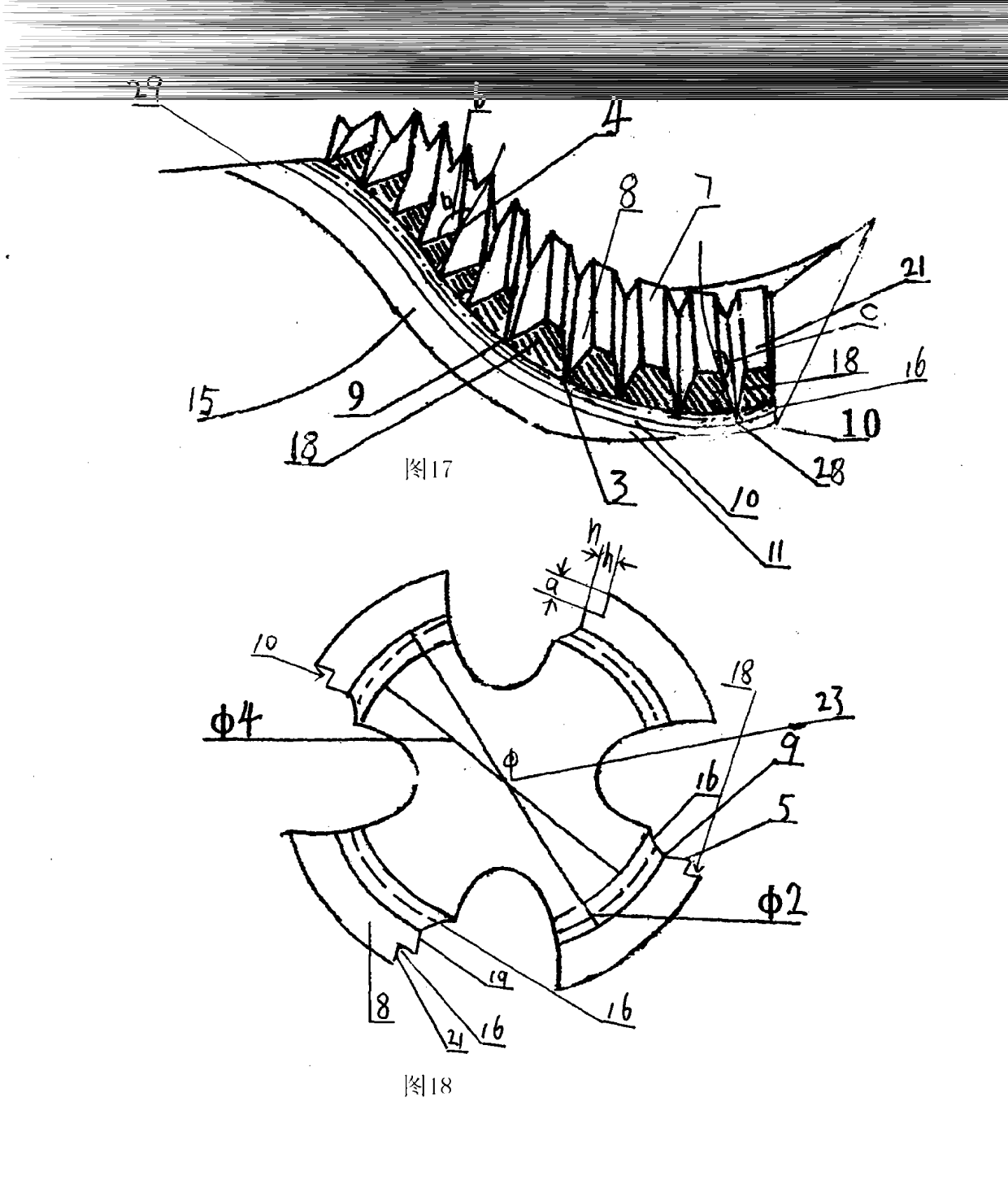

[0048] Such as Figure 5 , Figure 6 As shown, the split-diameter-guided compound cutting tap or compound cutting cone of the third embodiment, on the basis of the technical effects of the first and second embodiments, the present invention includes a tap body 1 and a shell 2, and the tap body 1 is connected or formed as one with the housing 2, or the taper body 1 and the housing 2, the taper body 1 and the housing 2 are connected or formed as one, and at least one thread body 1 is connected or integrated on the tap or the cone , or at least one spiral thread body 1, or at least one taper thread body 1, each thread body has a cutting edge surface 6 at the front of the split-diameter guide compound cutting tap or the axial front end of the compound cutting cone, cutting The side chamfering 8 on the back side of the cutting edge surface 6 at the entry point is the rear cutting surface 7, the outer surface of the cutting edge surface 6 is the side cutting surface 8, and the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com