Vehicle body assembly welding fixture

A welding fixture and assembly technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low personnel safety, difficulty in ensuring production rhythm, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

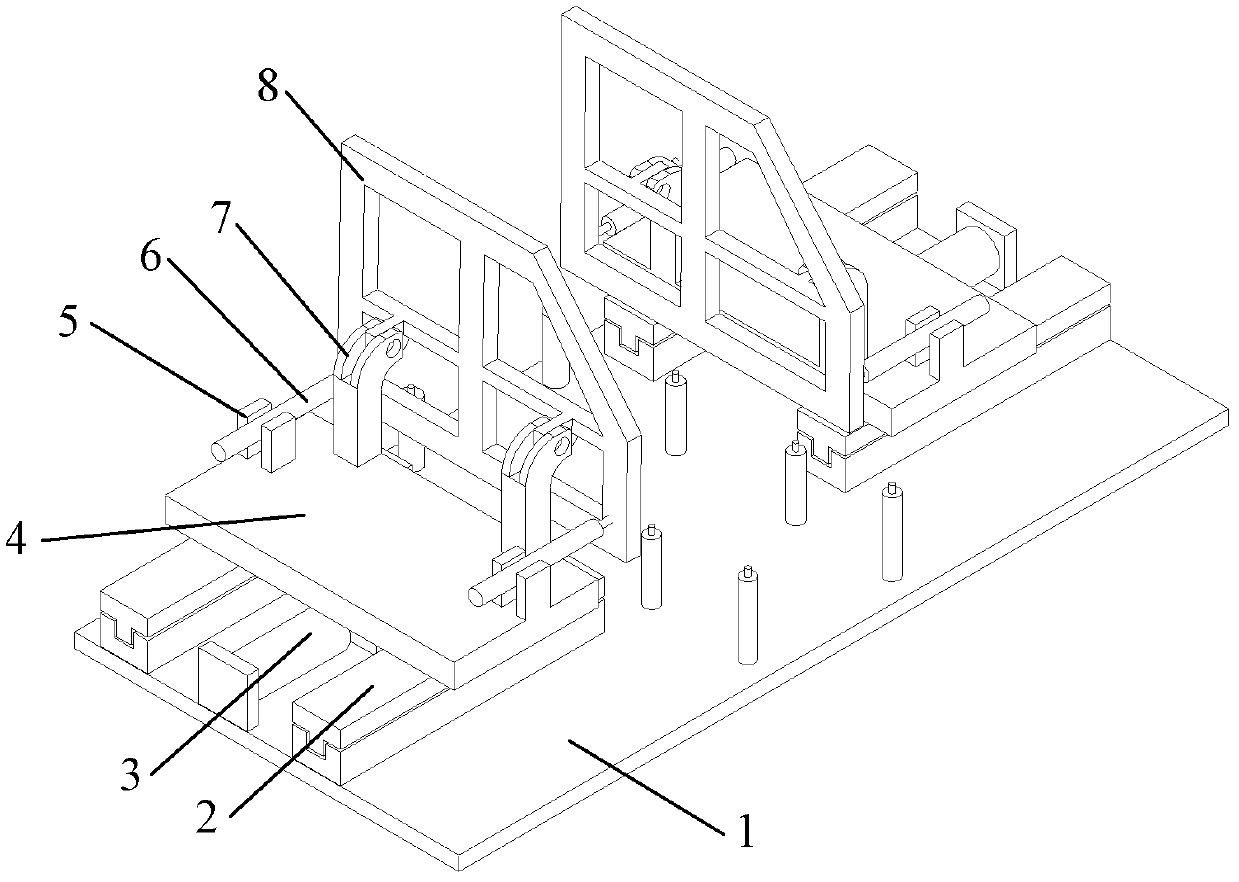

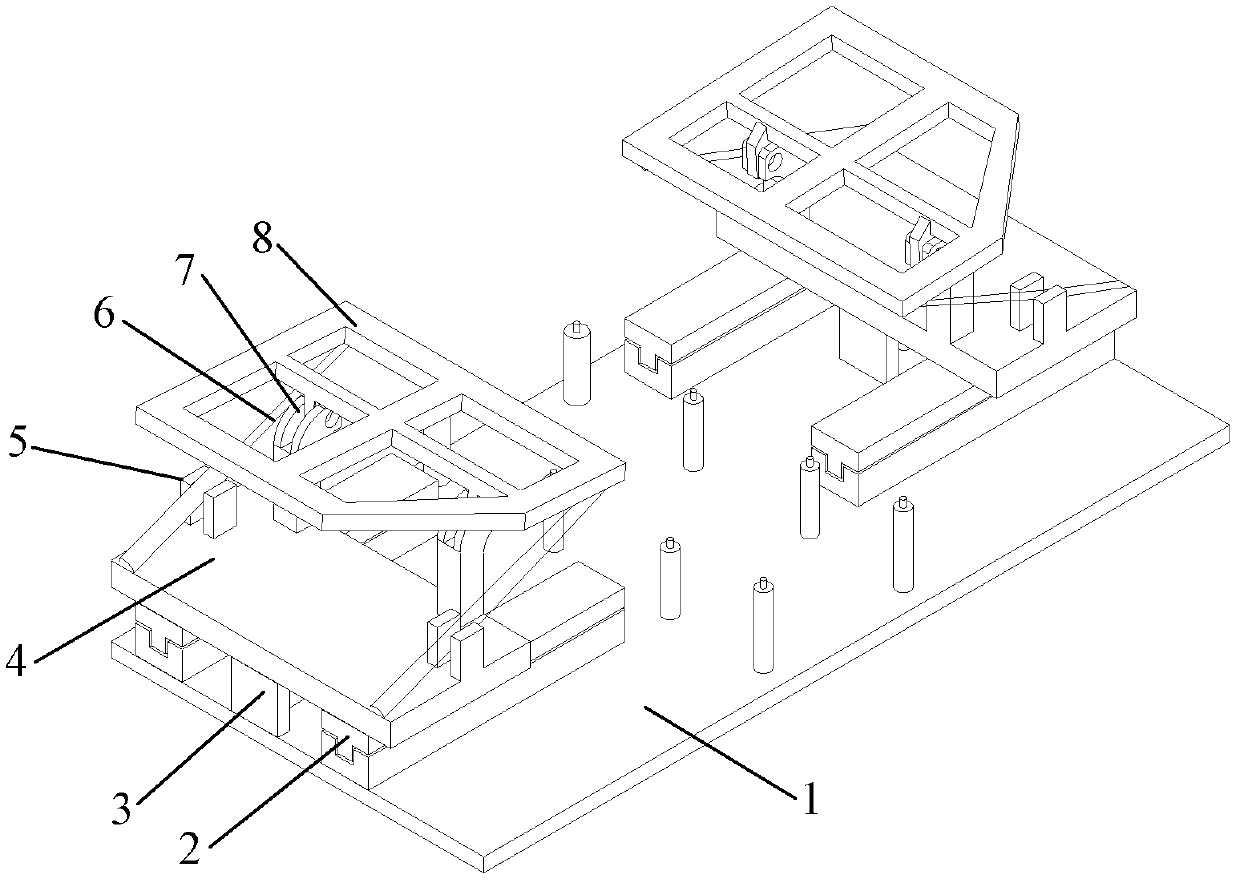

[0019] figure 1 It shows the structural diagram of the body assembly welding jig of this embodiment when it is not opened. As shown in the figure, it includes a base 1 and a vehicle body that is movable on the base 1 and whose angle with the base 1 can be adjusted. Side wall clamp bracket unit. The body side wall clamping bracket unit includes a left side wall clamping bracket module and a right side wall clamping bracket module with the same structure and arranged symmetrically. Since the structures of the clamping bracket modules on both sides are exactly the same, the detailed description of its structure will be described below only by taking the left side clamping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com