Tooth orthodontic correction material and preparation and application thereof

A technology for orthodontics and teeth, which is applied in the field of orthodontic materials for braces orthodontic materials with transparent polymer teeth, which can solve the problems of insufficient orthodontic stress, poor orthodontic effect, and insufficient elastic recovery force of polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

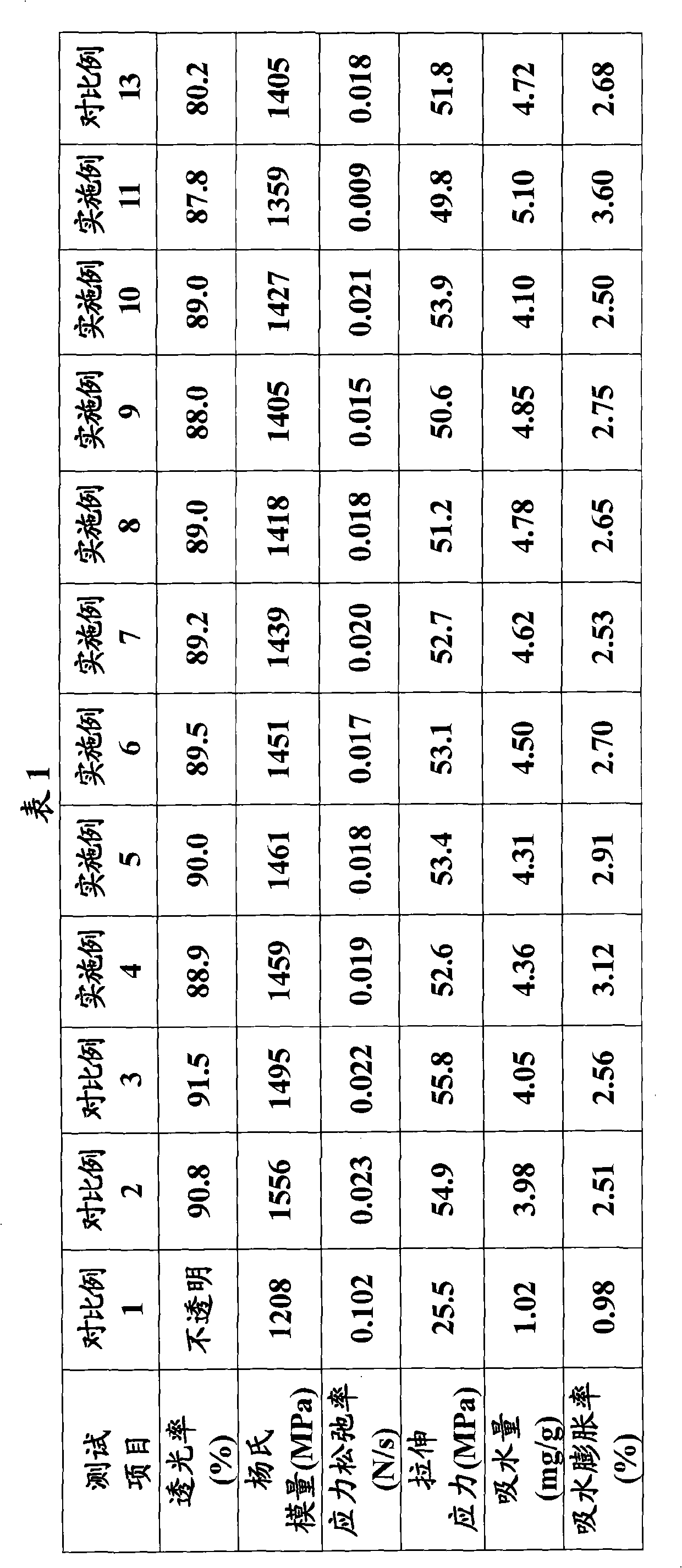

Examples

Embodiment

[0071] In the following comparative examples and examples, unless otherwise specified, all percentages are percentages by weight.

[0072] The raw materials used in each of the following examples and comparative examples are as follows:

[0073] A total of four types of polyethylene terephthalate-1,4-cyclohexanedimethanol are used, namely A-D:

[0074] A: Brand: BR003, American Eastman Chemical Company, 1,4-cyclohexanedimethanol monomer unit accounted for 40% by weight of the entire polymer, the weight average molecular weight was 250,000, and the light transmittance was 91%.

[0075] B: Brand: DN011, American Eastman Chemical Company, 1,4-cyclohexanedimethanol monomer unit accounted for 40% by weight of the entire polymer, the weight average molecular weight was 280,000, and the light transmittance was 90%.

[0076] C: Brand: Z6006, Eastman Chemical Company, USA, 1,4-cyclohexanedimethanol monomer unit accounts for 35% by weight of the entire polymer, the weight average molec...

Embodiment 4

[0095] Polyethylene terephthalate-1,4-cyclohexanedimethanol B (the proportion of 1,4-cyclohexanedimethanol is 40%, the molecular weight is 280,000), polycarbonate A (molecular weight 30000 ) and thermoplastic polyurethane A (hardness 80A), according to the ratio of 70%, 10% and 20% respectively in the mixer, stir and mix evenly, and then add 0.3% (the percentage of all components of the orthodontic material) and the antioxidant 1010 (commercially available) that is 100% by weight), mix uniformly to obtain the mixture, then feed the mixture into the twin-screw extruder, and control the extrusion temperature of each section from the entrance to the exit to be 225°C-235°C , extrusion, granulation. Dry the cast pellets at 80°C for 5 hours, and then perform injection molding in an injection molding machine to obtain samples that meet the national standards GB / T 16421-1996, GB / T1034-1998 and GB / T 2410-80 respectively. Performance tests were carried out in accordance with the aforem...

Embodiment 5

[0097] Polyethylene terephthalate-1,4-cyclohexanedimethanol C (the proportion of 1,4-cyclohexanedimethanol is 35%, the molecular weight is 250,000), polycarbonate B (molecular weight 32000 ) and thermoplastic polyurethane B (hardness 90A), according to the ratio of 70%, 10% and 20% respectively in the mixer, stir and mix evenly, and then add 0.3% (the percentage of all components of the orthodontic material) and the antioxidant 1010 (commercially available) that is 100% by weight), mix uniformly to obtain the mixture, then feed the mixture into the twin-screw extruder, and control the extrusion temperature of each section from the entrance to the exit to be 225°C-235°C , extrusion, granulation. Dry the cast pellets at 80°C for 5 hours, and then perform injection molding in an injection molding machine to obtain samples that meet the national standards GB / T 16421-1996, GB / T1034-1998 and GB / T 2410-80 respectively. Performance tests were carried out in accordance with the aforem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com