Automobile differential planet bevel gear spherical surface height detection gauge

A technology for automotive differentials and bevel gears, applied in the field of spherical height gauges for planetary bevel gears of automotive differentials, can solve problems such as inability to detect and correct size out-of-tolerance in time, difficulty in direct measurement, lack of quantitative gauges, etc., to achieve The effect of low detection environment requirements, simple structure, and convenient loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

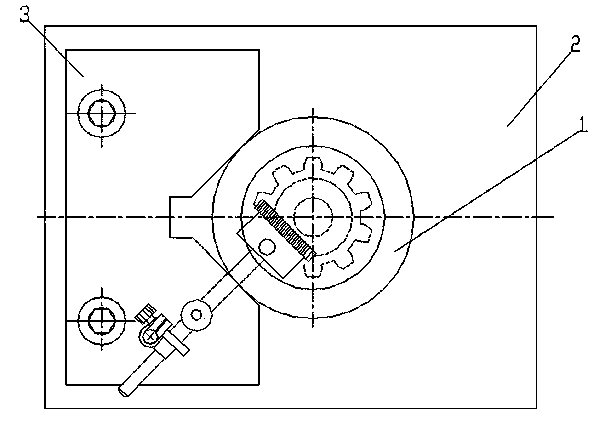

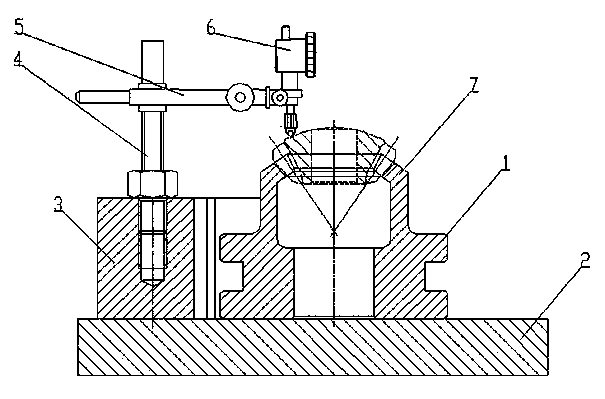

[0015] figure 1 The shown automotive differential planetary bevel gear spherical height gauge consists of a tooth mold 1, a flat plate 2, a base 3, a vertical bar 4, a cross bar 5 and a gauge 6. The base 3 is 90 0 V-shaped block, one side of the flat plate 2 is positioned and connected to the lying base 3, the V-shaped surface of the base 3 is perpendicular to the upper plane of the flat plate 2 to form a measurement datum, the vertical bar 4 is connected to the top side of the base 3, and the cross bar 5 Insert the rod 4 to form a cross-hinge connection structure, the outer end of the cross bar 5 locks the meter 6, and the measuring end of the meter 6 contacts the measuring part of the workpiece 7 downwards, and this structure is a measuring end with an adjustable position. Table tool 6 is a dial indicator in the present embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com