Electrode foils, current collectors, electrodes, and storage devices using these

A technology for current collectors and capacitor components, applied in the field of electrode foils, can solve the problems of tight electrical conductivity, insufficient chemical stability, difficult charging and discharging, and increased contact resistance, etc., to improve electrical conductivity and chemical stability. , good antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

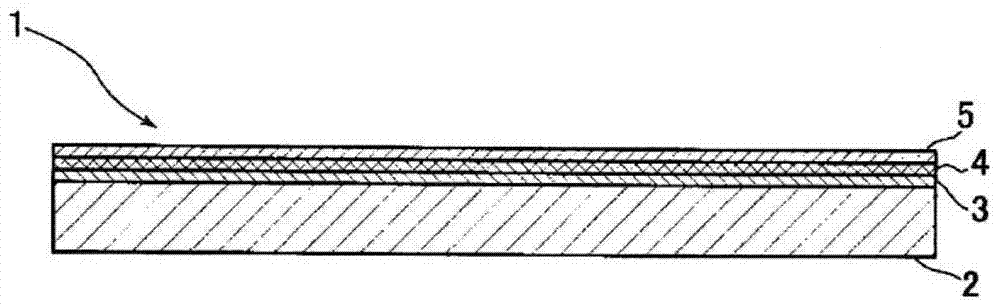

[0101] The following description: On the non-roughened aluminum foil, a first conductive layer composed of Ti or Al, a mixed layer composed of Ti or Al and carbon, and a second conductive layer composed of carbon are formed. Layered cathode foil, and a solid electrolytic capacitor fabricated using the cathode foil, are an embodiment of the present invention. However, as already explained, the aluminum foil used as the substrate and the Ti or Al used to form the first conductive layer can be replaced by other materials, or as explained by the performance test data, even if the surface of the substrate is not roughened Therefore, the cathode foil of the present invention also has good characteristics.

[0102] (cathode foil of the present invention)

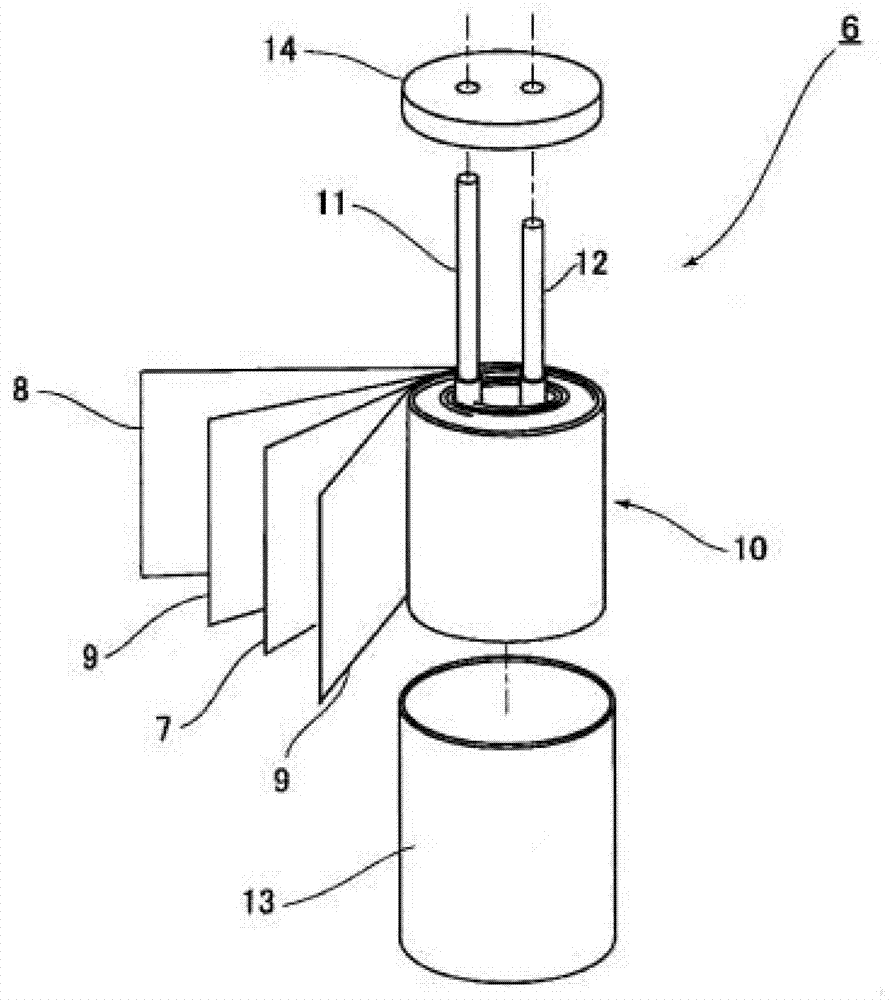

[0103] figure 1 It is a cross-sectional view showing the layer structure of the cathode foil 1 according to the above-mentioned one embodiment. The cathode foil 1 is: a smooth aluminum foil 2 that has not been roughened by etchi...

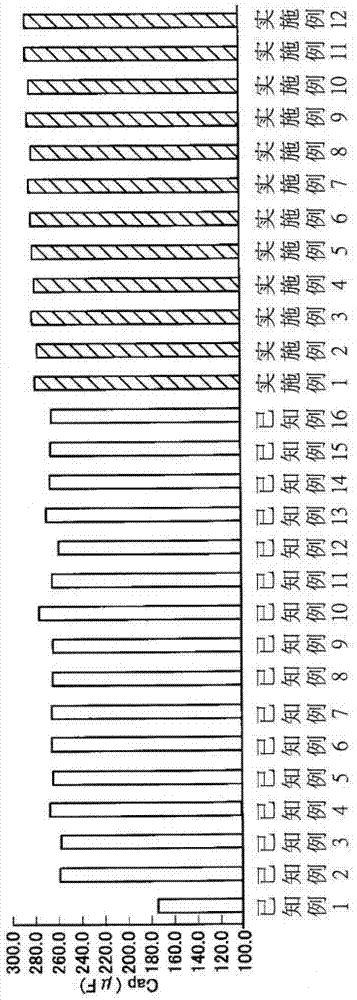

Embodiment 1

[0159] The smooth aluminum foil was etched to form a cathode foil having a Ti coating of 0.2 μm, a Ti and carbon mixed layer a of 0.1 μm, and a carbon coating of 0.2 μm.

Embodiment 2

[0161] The smooth aluminum foil was etched to form a cathode foil having a Ti coating of 0.008 μm, a Ti and carbon mixed layer a of 0.004 μm, and a carbon coating of 0.008 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap