Scale depositing basket

A fouling and sieve tray technology, applied in the field of fouling baskets, can solve the problems affecting the uniform distribution of the liquid phase in the catalyst bed, the length of the liquid phase flow path is different, and the formation of shell layers, etc., and achieves low weight and permeability. Good, to achieve the effect of catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

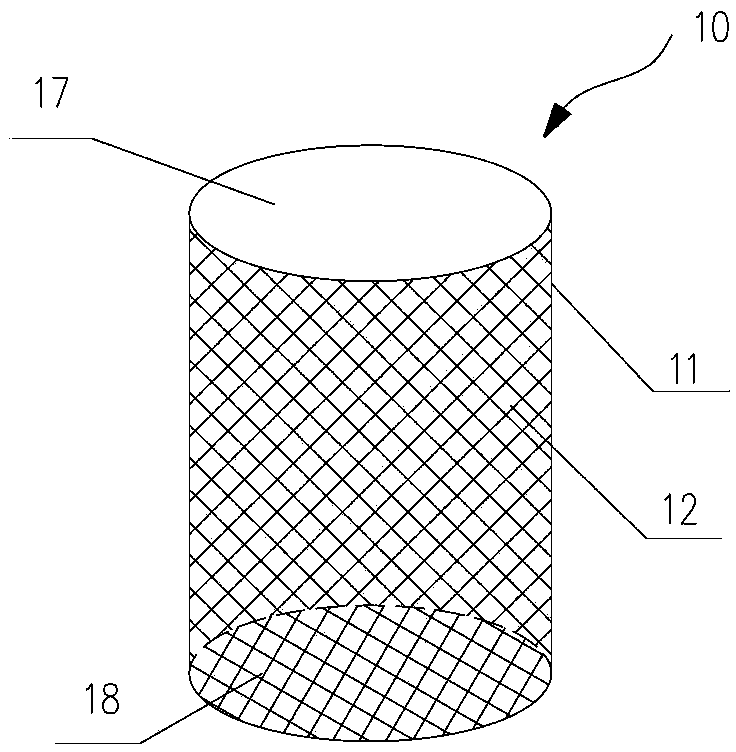

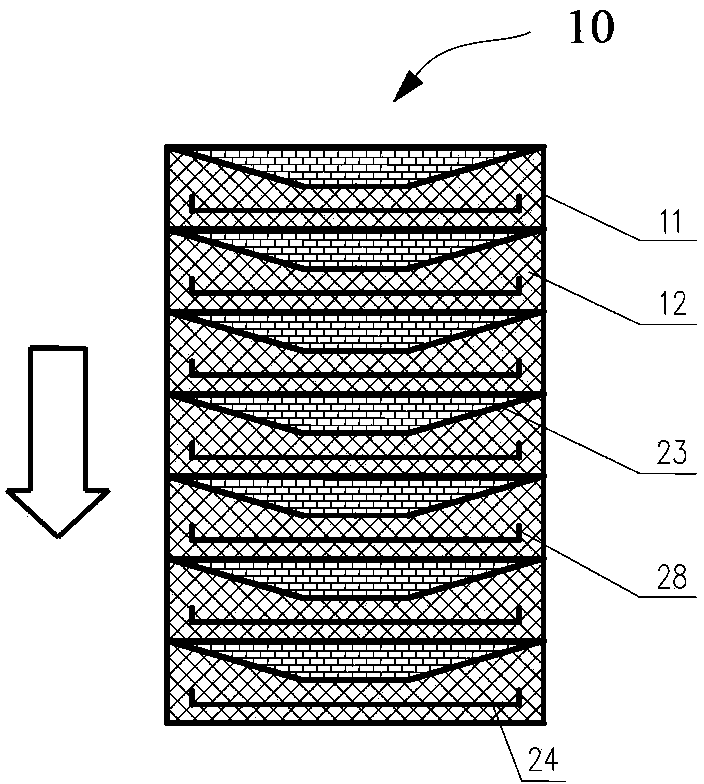

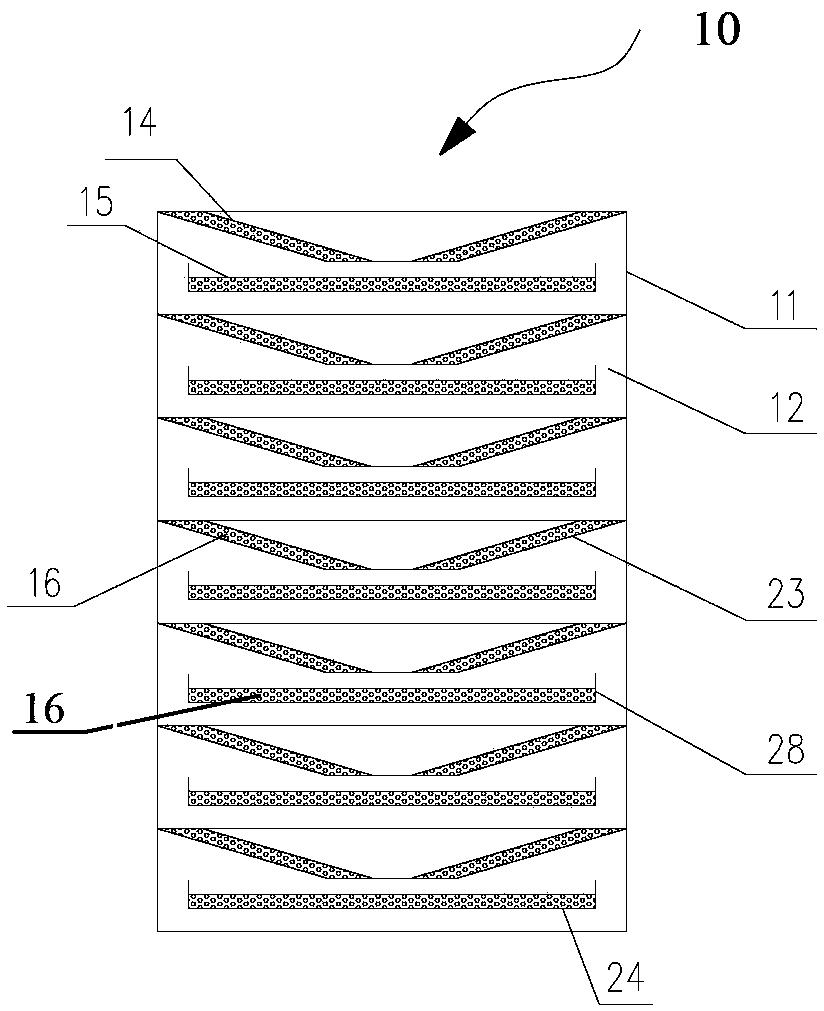

[0030] The fouling basket of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] figure 1 A schematic external view of a dirt basket 10 according to the invention is shown. It is a cylindrical structure, including a frame 11 and an outer screen 12 installed on the downstream end face 18 and the entire side of the frame 11 , while no outer screen 12 is installed on the upstream end face 17 of the frame 11 . The specification of the outer screen can be, for example, 40-60 mesh.

[0032] The dirt basket 10 according to the invention also comprises a plurality of sieve tray groups arranged in layers within the frame 11 . Wherein, each sieve tray group includes a body-shaped sieve tray and a surface-shaped sieve tray, and holes 25 are arranged on the body-shaped sieve tray along its longitudinal central axis. The screen of the sieve tray is chosen to have a denser mesh than the outer screen 12 . In one embodiment, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com