Rotary disc type sensing element with multiple magnets and unevenly distributed magnetic fluxes

A technology with uniform distribution and sensing elements, which is applied in power metering, vehicle components, torque metering, etc., can solve problems such as distortion and difference of power-assist demand models, and inconsistency between power-assist output and power-assist demand, and achieve low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

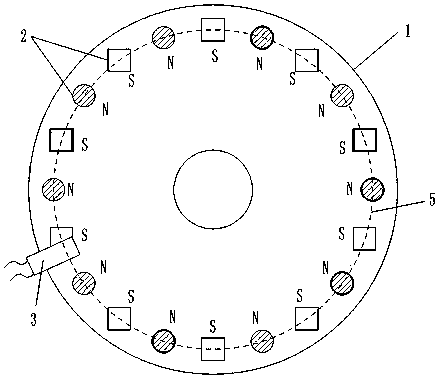

[0062] Embodiment 1. Rotary disk sensor element with non-uniform distribution of magnetic flux by multiple magnetic blocks

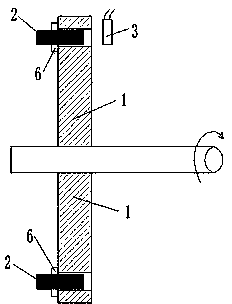

[0063] Such as figure 1 , 3 , 4, 5, 20 permanent magnet blocks 2 are fixedly arranged on the rotating disk 1 with a diameter of 10.0 cm by injection molding of a high-strength plastic.

[0064] All permanent magnet blocks 2 are evenly distributed in a circular trajectory, and each permanent magnet block 2 is fixed on a circular trajectory line 5 with a diameter of 9.0 cm, that is, the distance from each permanent magnet block 2 to the center of the circle where the circular trajectory line 5 is located is the same , The distance between adjacent permanent magnet blocks 2 is the same. The magnetic flux of the permanent magnet block 2 is 146---279 (B·H)max / KJ·m -3 Different selection values within the range, and the magnetic flux of adjacent permanent magnet block 2 is not equal. There are two permanent magnet blocks 2 and the holes on the rotating ...

Embodiment 2

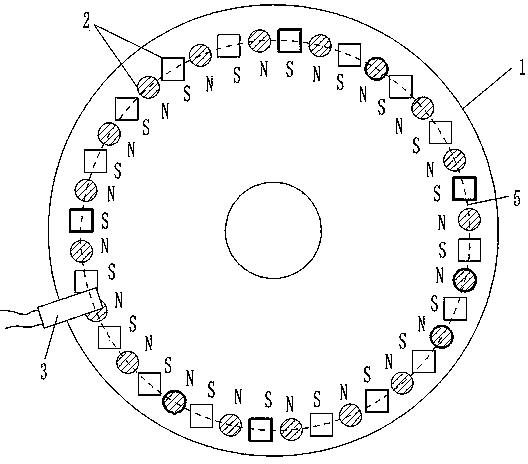

[0075] Embodiment 2. Rotary disk sensor element with uneven distribution of magnetic flux with high-density multi-magnetic blocks

[0076] Such as figure 2 , 3 , 4, 5, one surface of a high-strength aluminum rotating disk 1 with a diameter of 10.0 cm is provided with 40 permanent magnet blocks 2 with a diameter of 0.4-0.6 cm. The magnetic flux of the permanent magnet block 2 is 146---279 (B·H)max / KJ·m -3 Different selection values within the range, and the magnetic flux of the adjacent permanent magnet block 2 is not equal, Hall 3 keeps a distance of 0.2 cm from each permanent magnet block 2 in the rotating state, so that each permanent magnet block 2 that is rotating Hall 3, Hall 3 can generate a corresponding rectangular wave electrical signal output. The structures of other rotating disk 1, permanent magnet block 2, and Hall 3 are the same as those in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com