Itch-preventing hemp core wrap yarn and processing method thereof

A processing method and technology of covered yarn, which is applied in the field of covered spinning, can solve the problems of not being able to change the fiber structure and performance, not being able to significantly reduce the bending stiffness of fabric surface hairiness, not alleviating or even eliminating the itching of linen fabrics, etc., to achieve The effect of avoiding itching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

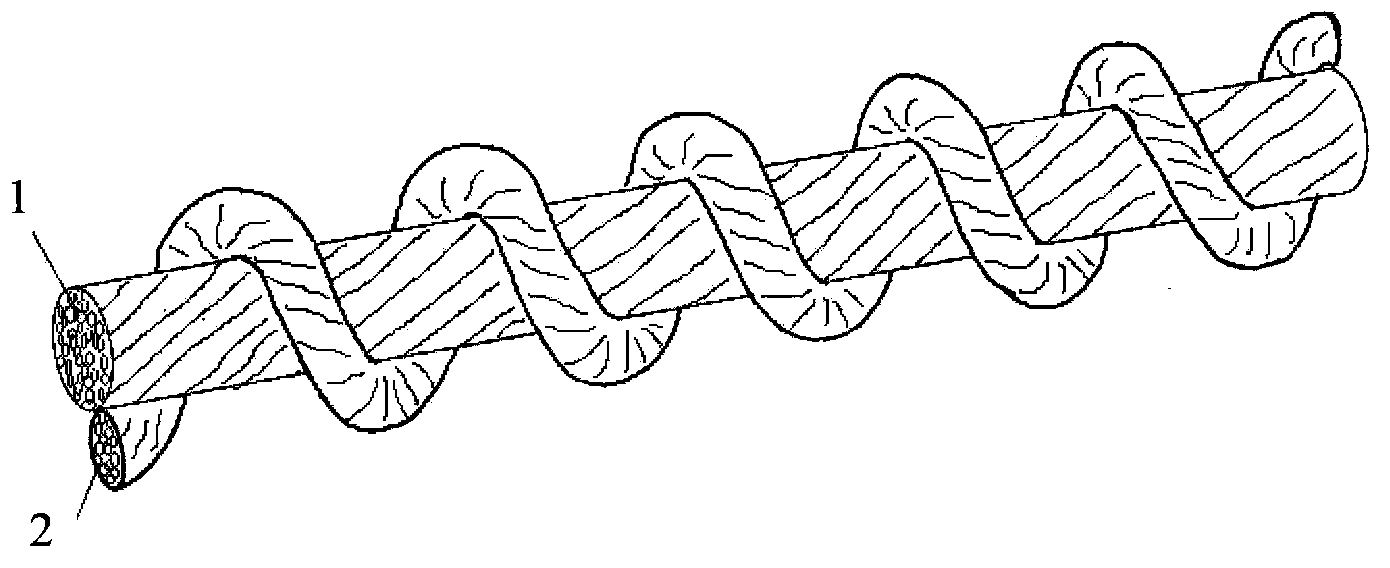

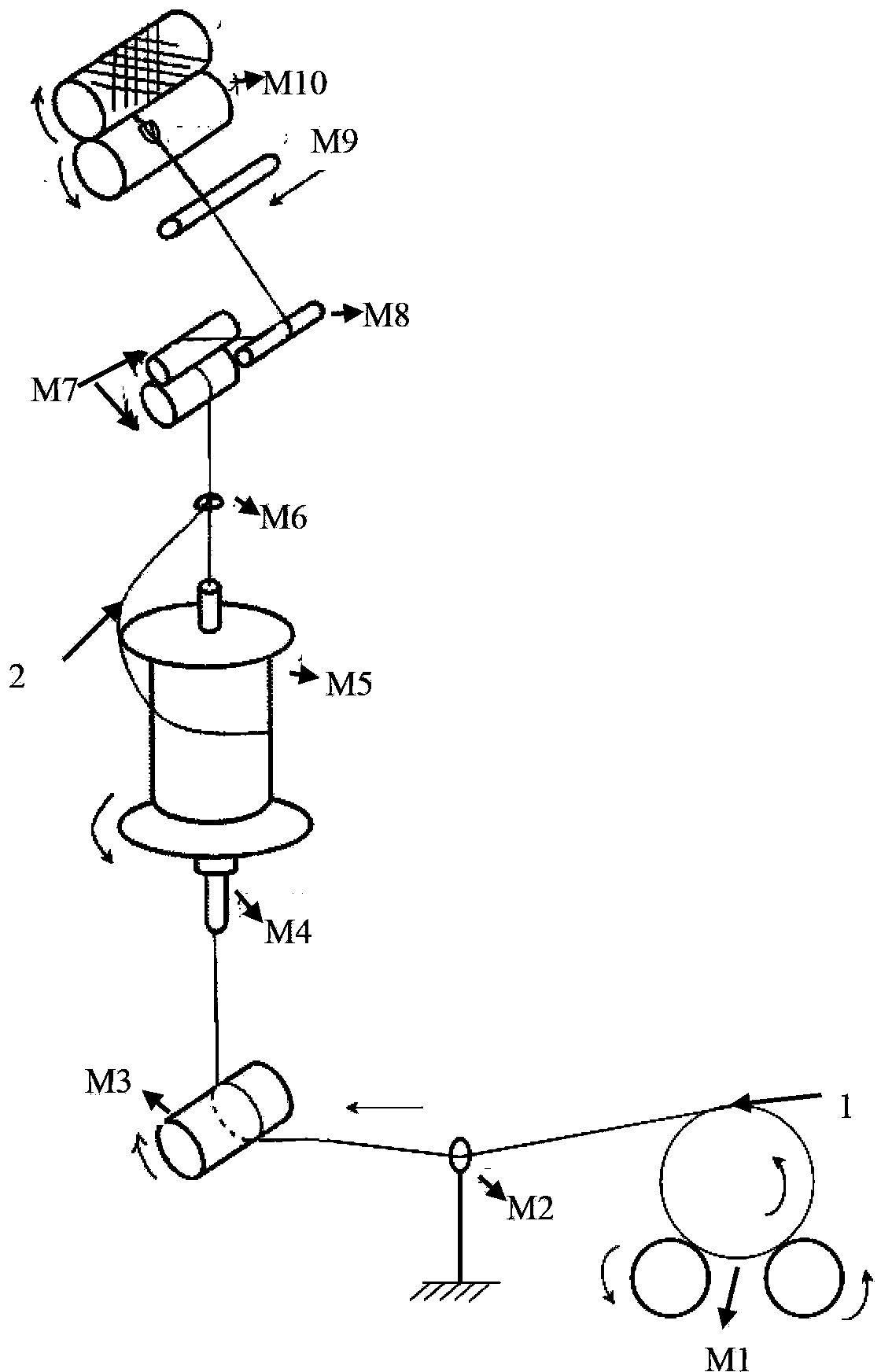

[0029]The ramie yarn is used as the yarn core, and the wrapped yarn is cotton yarn. On the hollow spindle covered spinning machine, the covered yarn is spun by single wrapping process. The ramie yarn density is 36 pounds, and the cotton yarn is 60 pounds. The production process parameters are: spindle speed 12000r / min, wrapping twist 1000 twists / m.

[0030] Due to the use of wrap spinning, the cotton yarn is wrapped around the ramie yarn to form a wrapped structural yarn with cotton as the outer layer and ramie yarn as the core. Due to the binding and isolation of the wrap spinning yarn, the hairiness of the hemp yarn (ramie fiber end) can be significantly reduced. ) the probability of contact with the skin, thus eliminating the itching of the fabric. Due to the high bending stiffness of ramie fiber, a larger wrapping twist is adopted to ensure that the possibility of contacting the ramie fiber end with the skin is minimized.

[0031] The yarn has both the moisture absorption...

Embodiment 2

[0033] The linen yarn is used as the core yarn, and the nylon DTY filament is used as the outer wrapping yarn. On the hollow spindle covering spinning machine, the covering yarn is spun by a single wrapping process. The specification is 70D / 24F, and the production process parameters are: spindle speed 11800r / min, wrapping twist 800 twists / m.

[0034] Due to the use of wrap spinning, nylon multifilament is wrapped around the linen yarn to form a wrapping structure yarn with nylon outer layer and flax yarn as the core. Fiber end) the probability of contact with the skin, thus eliminating the itching of the fabric. Since the flexural stiffness of flax fiber is lower than that of ramie, a moderate wrapping twist can ensure better tactile comfort of the fabric.

[0035] The outer covering nylon yarn has good wear resistance and elasticity, and the core yarn linen yarn endows the yarn with good moisture absorption and release properties, which is suitable for processing shirts and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com