Color laser phototypesetting sheet

A technology of color laser and color filter layer, which is applied in the direction of optics, optical components, photosensitive material base/auxiliary layer, etc., can solve the problem of difficult to ensure that the phototypesetting image and the color plate image are closely connected, difficult, and accurate. Bit and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

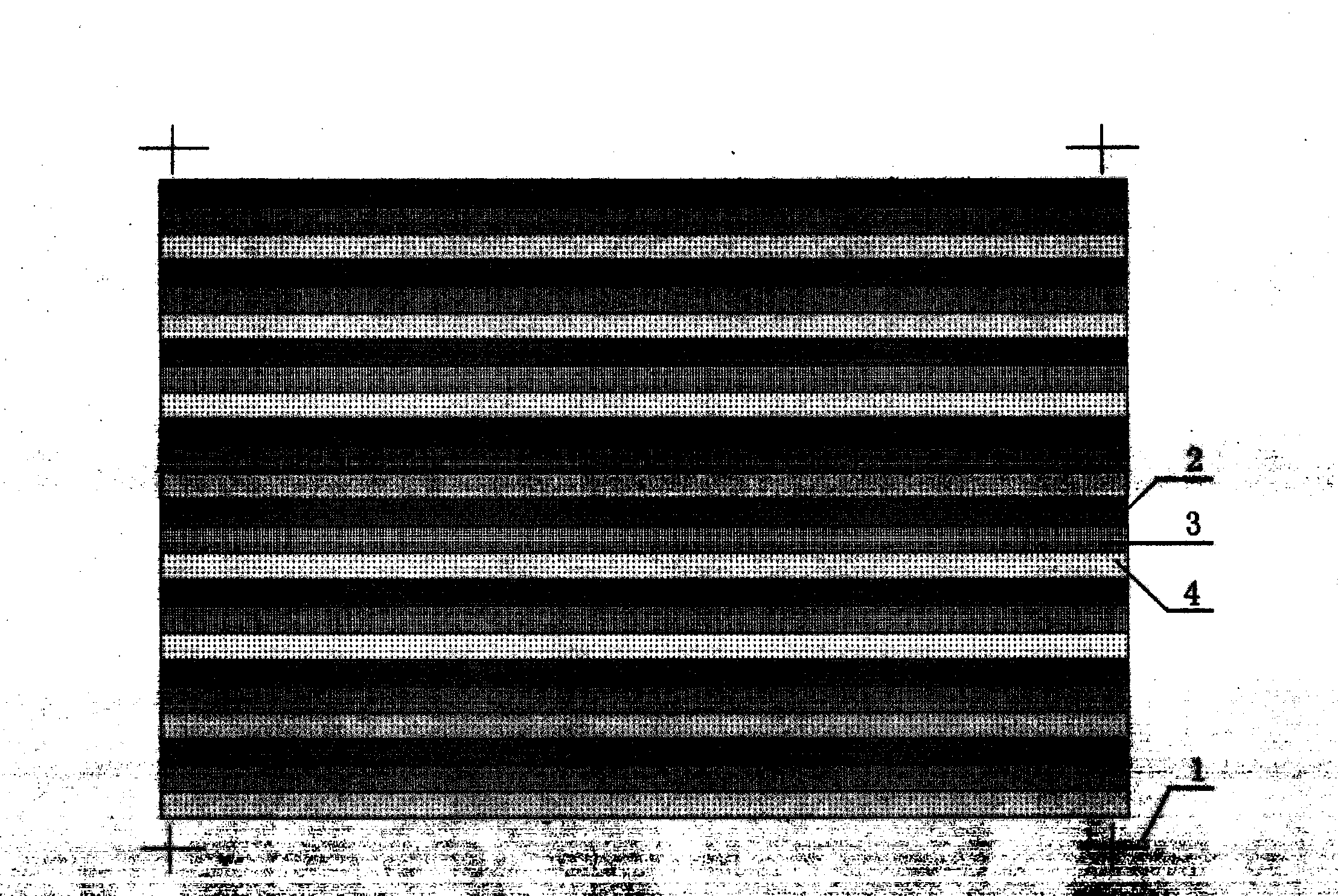

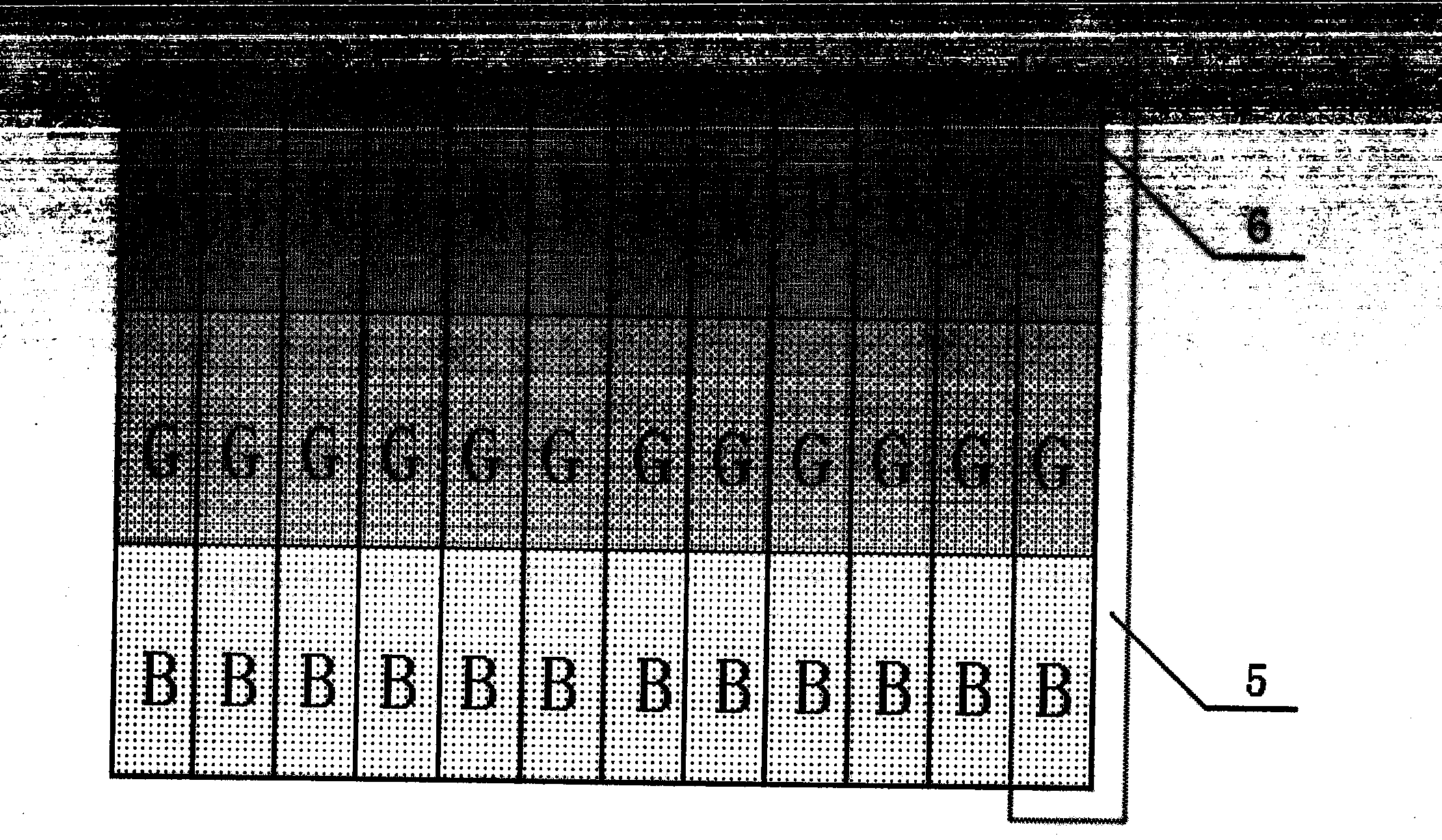

[0018] Implementation case 1: Prepare a laser film sheet for mask and mount it on transparent glass. The mask pattern is a slit grating of 800mm*800mm, surrounded by a light-shielding belt with a width of 50mm, and the width of the light-transmitting strip of the slit grating is w , the width of the shading strip is 2w, where w is the designed width of the filter strip of the color filter layer. The mask glass is closely attached to the full-transparent color photosensitive lamp sheet and exposed with a red LED light; then the mask glass is moved a distance w in the vertical direction of the grating line, and exposed with a green LED light; again, the mask glass is exposed in the vertical direction of the grating line Move w distance up and expose with blue LED light. After processing, obtain a color filter layer mask negative film composed of periodic cyan, magenta, and yellow filter strips, mount it on transparent glass, and block it with a black light-shielding tape with a ...

Embodiment example 2

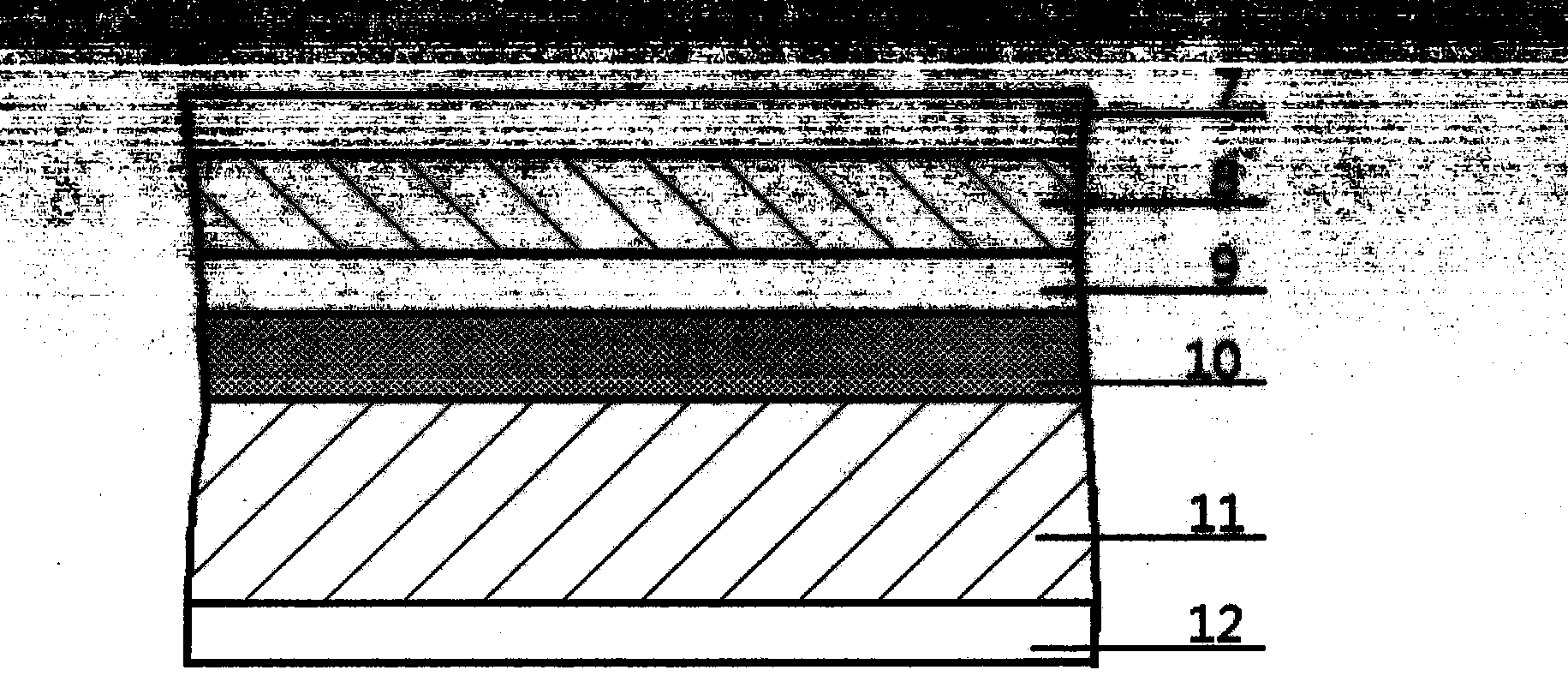

[0019] Implementation Case 2: Engraving three gravure rolls with lasers. The patterns on the rolls are periodic solid lines with a line width of w and a line interval of 2w. The lines form a complete circle around the rolls. Between the solid lines on the three rolls The dislocation distance between them is w, and the color filter layer is printed on the film base with R, G, and B spot color inks with excellent color rendering properties, and then coated with a bonding layer, a photosensitive emulsion layer, and a protective layer, light-shielding and sealed, and packaged into Finished color laser phototypesetting.

[0020] In the present invention, it is feasible to add more coatings between the film base and the photosensitive emulsion layer to improve performance; the arrangement order of the RGB filter strips on the color filter layer is interchanged, and the direction of the lines is parallel to the film base reel , vertical, and at a certain inclination angle are also fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com