Plant drink and preparation method thereof

A technology for plant beverages and raw materials, applied in the field of beverage processing, can solve the problems of reduced nutritional and health care value, limited consumer groups, unsuitable drinking for diabetics, etc., and achieves the effects of simple preparation process, pure and transparent color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

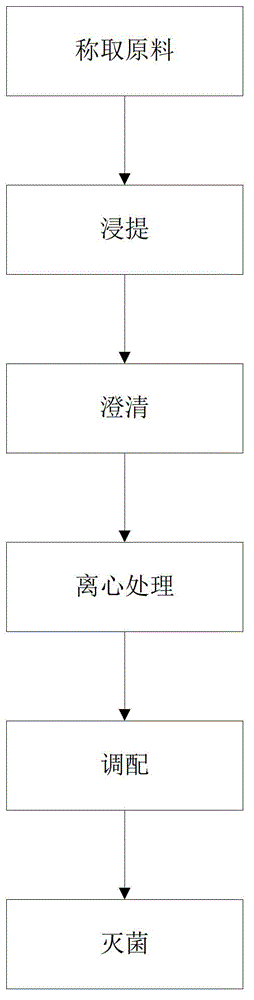

[0034] figure 1 A schematic flow diagram showing the preparation method of the plant beverage of the present invention. Such as figure 1 As shown, the raw materials required for preparing the plant beverage are first weighed: honeysuckle and chrysanthemum, and the weight ratio of the two is: 60-75% of honeysuckle and 25-40% of chrysanthemum. Preferably, the weight ratio of the two is 70% of honeysuckle and 30% of chrysanthemum. Before weighing the raw materials, the honeysuckle and chrysanthemums can be dried. In one embodiment of the present invention, the honeysuckle and chrysanthemum are dried at 40° C. to constant weight.

[0035] After the raw materials are prepared, the raw materials in the weight ratio are added into water for leaching, and the weight of the water is 15-25 times of the weight of the honeysuckle, preferably 20 times. After leaching at 70-90° C. for 1-3 hours, filter to obtain an extract. Preferably, the extraction temperature is 80° C., and the extr...

Embodiment 1

[0048] Weigh 60kg of honeysuckle and 40kg of chrysanthemum, add the two into 900kg of water, and extract 3 times at 90°C for 3 hours each time. After leaching, filter, and combine the three filtrates to obtain the extract. Chitosan was added to the extract, and it was allowed to stand at room temperature for 2 hours to obtain a clear solution, wherein 0.8 kg of chitosan was added per ton of the extract. The clarified liquid was centrifuged for 15 min at a centrifuge speed of 2500 r / min, and then suction filtered to obtain a fine filtrate. Then add its 2 times the weight of water in the fine filtrate to dilute. Then add sodium carboxymethyl cellulose and concentration to be 50% xylitol solution to prepare in the fine filtrate after dilution, wherein add 50kg xylitol solution and 0.2kg carboxymethyl in the fine filtrate after every ton of described dilution Sodium cellulose. After the preparation is completed, the preparation solution is sterilized at 95° C. for 15 minutes, a...

Embodiment 2

[0050] Weigh 65kg of honeysuckle and 35kg of chrysanthemum, add the two into 1170kg of water, extract 3 times at 75°C, 1 hour each time. After leaching, filter, and combine the three filtrates to obtain the extract. Chitosan was added to the extract, and it was allowed to stand at room temperature for 4 hours to obtain a clear solution, wherein 0.9 kg of chitosan was added per ton of the extract. The clarified liquid was centrifuged for 5 min at a centrifuge speed of 3500 r / min, and then suction filtered to obtain a fine filtrate. Then add 3 times its weight of water in the fine filtrate to dilute. Then add carboxymethylcellulose sodium and concentration to the xylitol solution of 50% in the fine filtrate after dilution and prepare, wherein add 55kg xylitol solution and 0.25kg carboxymethyl in the fine filtrate after every ton of described dilution Sodium cellulose. After the preparation is completed, the preparation solution is sterilized at 100° C. for 15 minutes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com