Continuous die using flanging knife flanging and sheet metal flanging processing method

A processing method and technology of sheet metal parts, applied in the field of flanging processing of sheet metal parts, can solve problems such as insufficient product quality, long processing process, and bulky volume, and achieve simplified structure and use methods, high product quality, and technological process simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

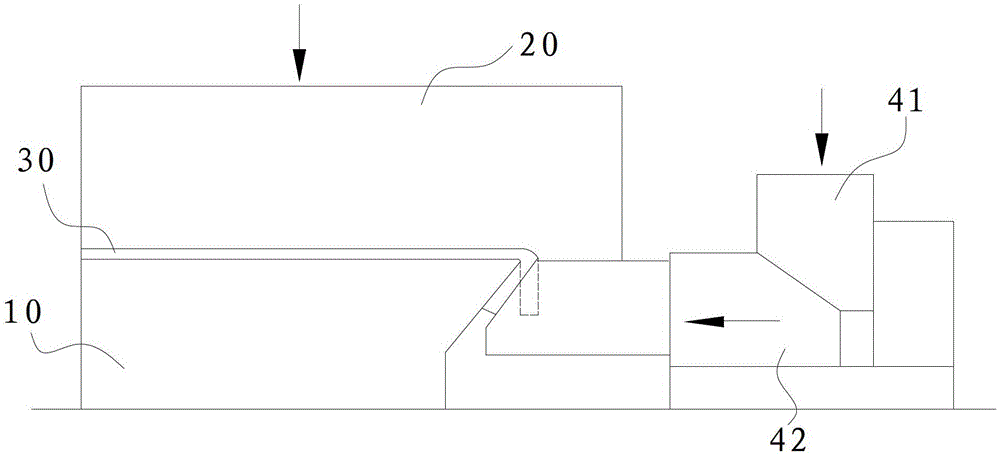

Image

Examples

Embodiment 1

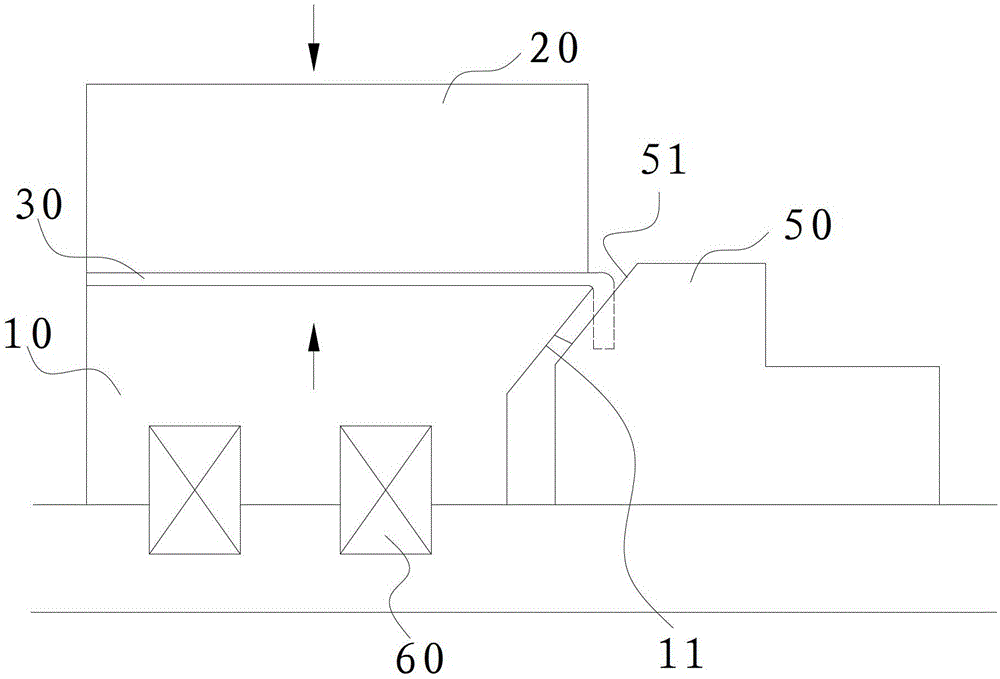

[0031] Such as figure 2 As shown, the preferred embodiment provides a continuous mold using a flanging knife to flanging, the continuous mold is provided with a flanging station, the flanging station is provided with a lower mold 10 and a mold that is compatible with the lower mold 10 The upper die 20, the flanging knife 50 fixedly arranged beside the lower die 10, and the spring arranged under the lower die 10.

[0032] The flanging station is divided into two sub-stations, and a flanging knife 50 is set on each sub-station. The angle of the processing surface 51 on the first divisional station flanging knife 50 is 60 ° (60 ° angle with the preformed shape), and the processing surface 51 angle on the second divisional position flanging knife 50 is 0 ° (with the preformed shape). parallel to the shape).

[0033] Correspondingly, the angle of the lower mold processing surface 11 of the first sub-station is 60°, and the angle of the lower mold processing surface 11 of the sec...

Embodiment 2

[0041] This preferred embodiment provides a continuous mold for flanging using a flanging knife, the basic structure of which is the same as that of the first preferred embodiment.

[0042] The difference is that: when the upper mold is lifted, the lifting of the lower mold is not limited to the spring, and any reset device that can realize the reset function can be used. The number of sub-stations included in the flanging process is not limited to two, and is determined according to the specific shape and processing conditions of the workpiece. Correspondingly, the angle of the processing surface of the flanging knife used in each sub-station increases sequentially to finally meet the set flanging angle requirements.

[0043] The processing flow of this preferred embodiment is also the same as that of the first substrate of the preferred embodiment. The difference is that decomposing the flanging process into multiple steps or one-step flanging depends on the specific produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com