Manufacturing method of golf iron rod head

A golf and club head technology, applied in the field of golf iron club head manufacturing, can solve the problems of time-consuming and labor-intensive manufacturing process, low production capacity, difficult to control quality, etc., and achieve the effect of reducing cost, reducing processing and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

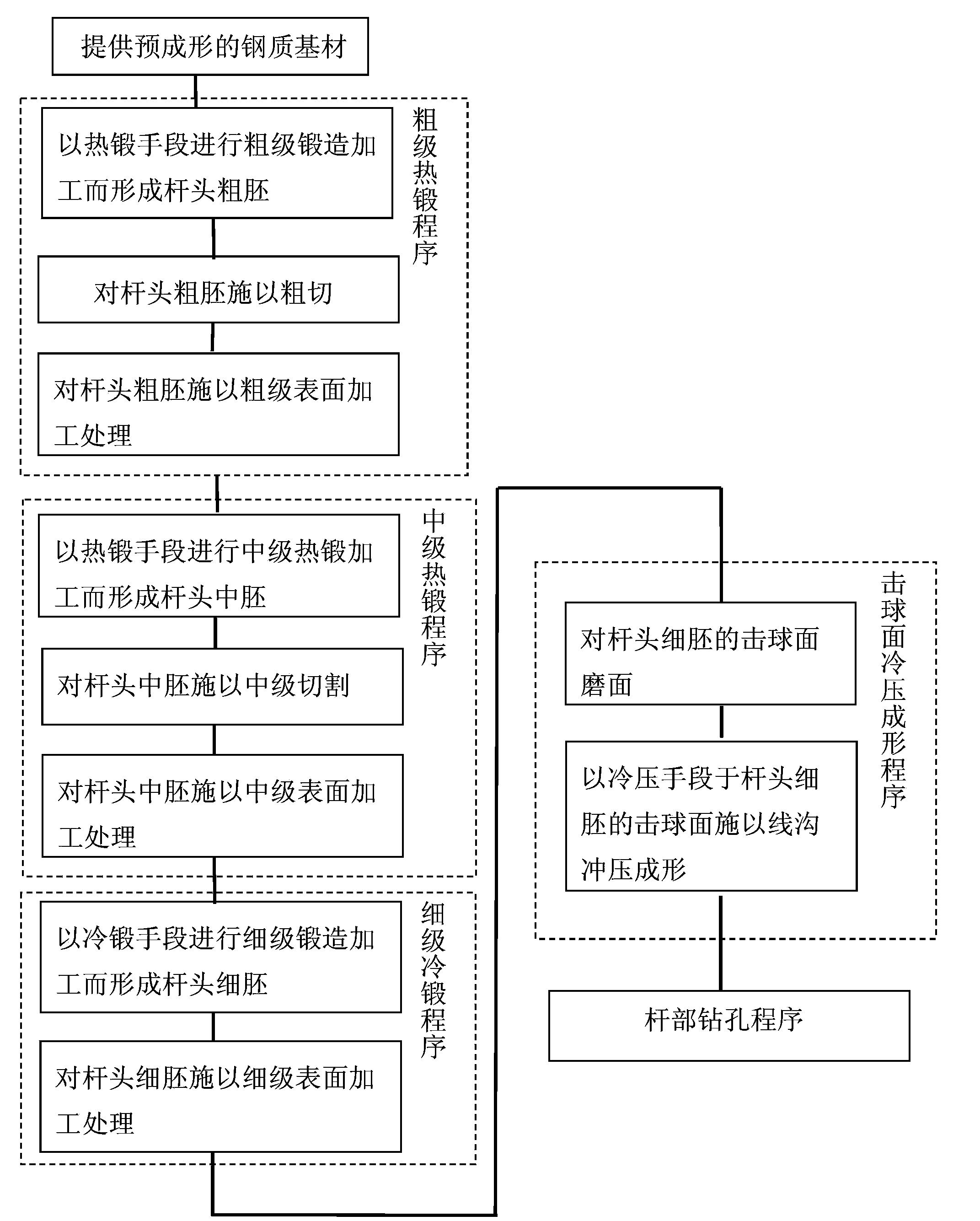

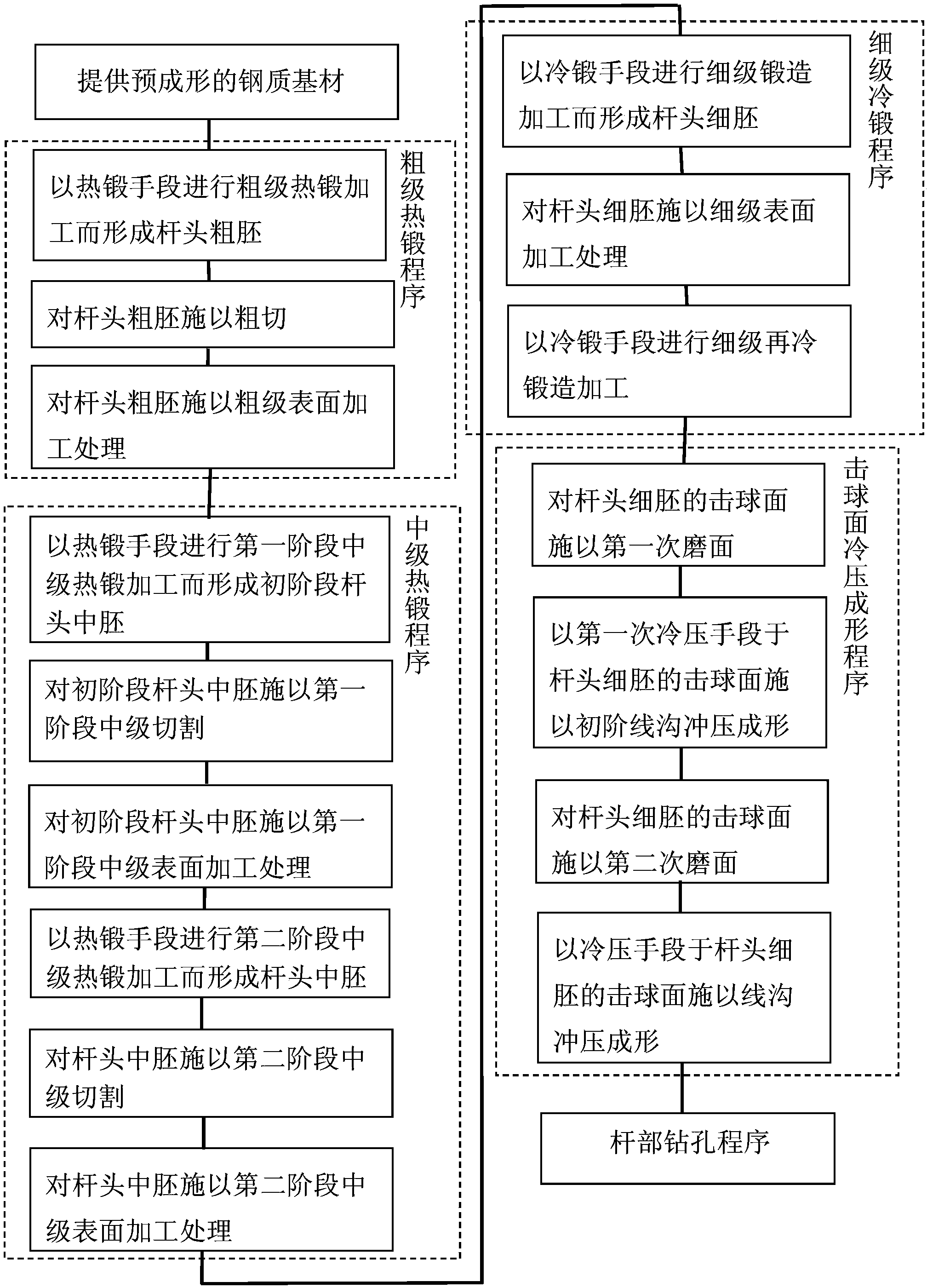

[0060] like figure 1 and figure 2 As shown, various preferred embodiments of the method of manufacturing an iron golf club head according to the present invention are disclosed. The method of manufacturing an iron club head includes: providing a preformed steel base material, and The material is sequentially subjected to a rough hot forging procedure, an intermediate hot forging procedure, a fine grade cold forging procedure, a cold pressing forming procedure of the hitting face and a drilling procedure of the rod portion to form the iron club head.

[0061] The preformed steel base material provided can be cut into a steel base material of a predetermined size from a steel bar, and then the steel base material after cutting is subjected to bending processing, wherein about 110 tons of steel base material is applied by a machine tool (T) Power bends the cut steel substrate into a predetermined shape, and the force exerted by the aforementioned machine tool is adjusted accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com