Detection method and system for elevator load

A detection method and detection system technology, which is applied in the electronic field, can solve problems such as high requirements for installation space, high use environment, full-loaded elevators, and large control boards, and achieve small signal transmission distances, high safety, and accurate signal acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

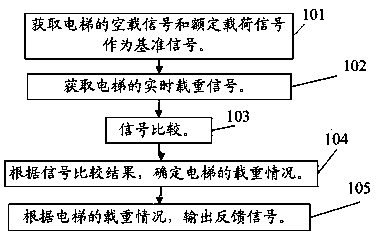

[0031] figure 1 It is a schematic flowchart of an elevator load detection method provided in this embodiment.

[0032] see figure 1 As shown, the elevator load detection method provided in this embodiment mainly includes the following process steps.

[0033] Step 101: Obtain the no-load signal and the rated load signal of the elevator as reference signals.

[0034] The reference signal is the basis for judging the load condition of the elevator, which can be pre-stored or externally input, or obtained by self-adjustment.

[0035] In this embodiment, it is obtained by self-debugging. The no-load signal is the elevator real-time load signal obtained under the elevator no-load condition; the rated load signal is the elevator real-time load signal obtained under the elevator rated load condition.

[0036] Step 102: Obtain the real-time load signal of the elevator.

[0037] The described acquisition of the real-time load signal of the elevator specifically includes:

[0038] D...

Embodiment 2

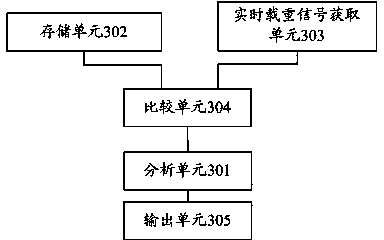

[0053] figure 2 It is a schematic structural diagram of an elevator load detection system provided by Embodiment 2 of the present invention.

[0054] see figure 2 As shown, the elevator load detection system mainly includes: an analysis unit 301 , a storage unit 302 , a real-time load signal acquisition unit 303 , a comparison unit 304 , and an output unit 305 . The connection relationship between each unit is as follows:

[0055] The storage unit 302 and the real-time load signal acquisition unit 303 are electrically connected to the comparison unit 304 , the comparison unit 304 is electrically connected to the analysis unit 301 , and the analysis unit 301 is electrically connected to the output unit 305 .

[0056] The analysis unit 301 is configured to determine the load condition of the elevator according to the comparison result of each of the reference signals of the elevator and the real-time load signal.

[0057] The storage unit 302 is configured to store the refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com