Coke oven heat-state pumping grouting construction method

A construction method and coke oven technology, which are applied to the heating of coke ovens, coke ovens, and coke oven parts, etc., can solve the problems of large physical energy consumption of workers, restricting construction progress, low work efficiency, etc., so as to shorten the construction period and reduce solidification. The effect of speed and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

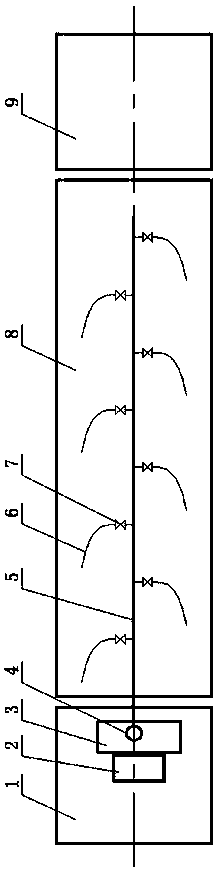

[0020] See attached figure 1 , The coke oven thermal pumping grouting construction method disclosed in the present invention is constructed according to the following steps.

[0021] a. The intermediate platform 1 and the end platform 9 are respectively arranged on both sides of the coke oven, the mud mixer 2 is arranged on the intermediate platform 1 on one side of the coke oven, and a mud storage box 3 is arranged in front of the mud mixer 2. The mud storage box is generally A rectangle whose size is made on-site according to usage. A vertical mud pump 4 is housed in the mud storage box 3, and the present embodiment adopts a PNL vertical mud pump.

[0022] b. Set up a support frame with a height of 500-600mm on the coke oven roof 8, the scaffolding on the construction site is enough, fix the main mud pipeline 5 on the support frame, and fix the main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com