Refrigeration device

A refrigeration device and refrigerant technology, which is applied in refrigerators, refrigeration and liquefaction, base materials, etc., can solve the problems of viscosity drop and affect the reliability of compressors, and achieve improved oil return, good solubility, improved reliability and The effect of system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

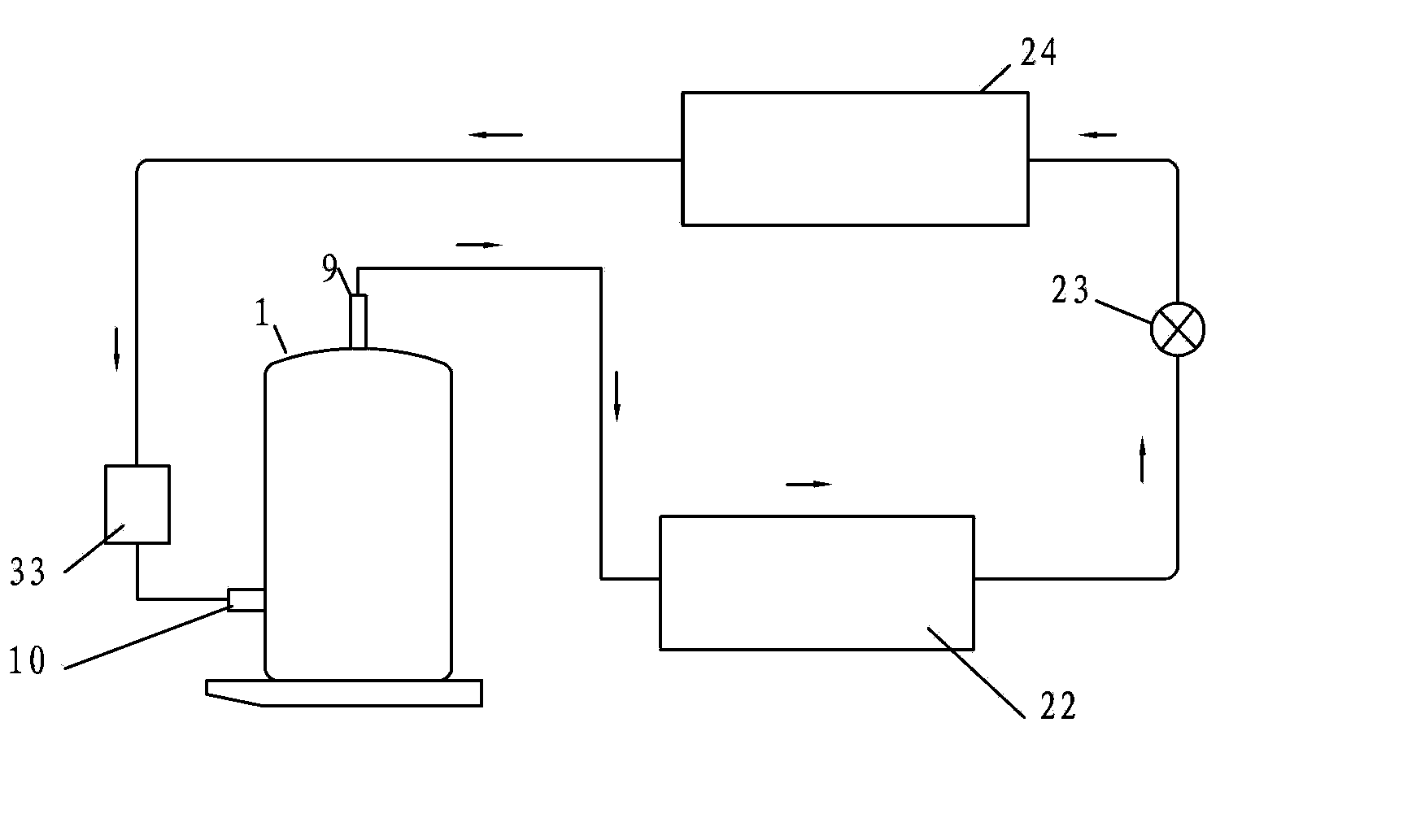

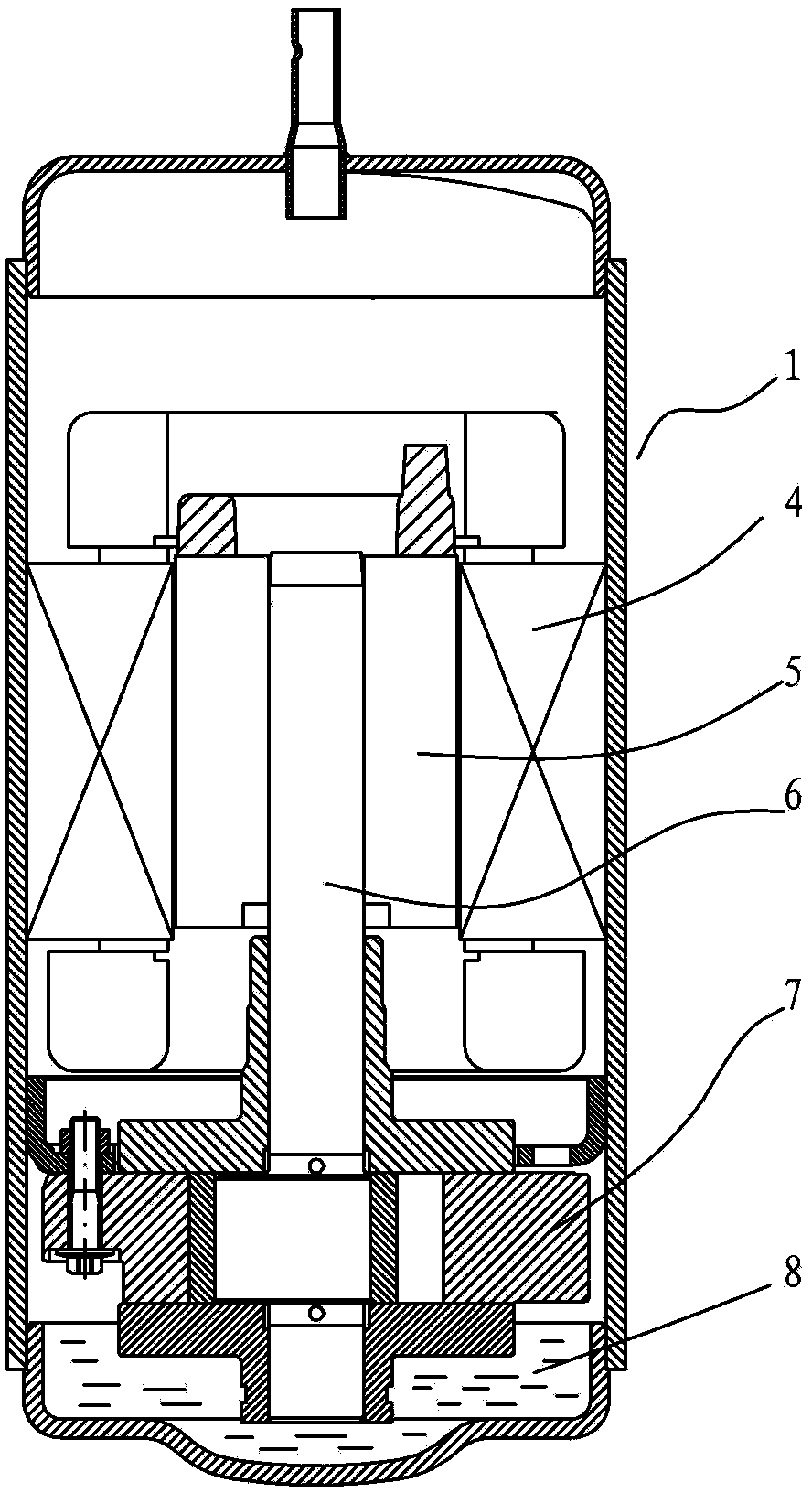

[0021] see Figure 1-Figure 2 , the refrigerating device includes a refrigerating cycle at least composed of a compressor 1, a condenser 22, an expansion mechanism 23 and an evaporator 24, the refrigerating cycle is filled with R32 refrigerant and refrigerating machine oil, and the refrigerating machine oil is composed of the first multi-component Alcohol ester and the second polyol ester are mixed, the first polyol ester satisfies general formula 1, the second polyol ester satisfies general formula 2,

[0022] General formula one;

[0023] General formula two;

[0024] Wherein, R1, R2, R3 and R4 are respectively alkyl groups with 1 to 9 carbon atoms, and R1', R2', R3' and R4' are respectively alkyl groups with 8 to 16 carbon atoms.

[0025] The two-layer separation temperature of the first polyol ester and the R32 refrigerant is below -10°C, and the two-layer separation temperature of the second polyol ester and the R32 refrigerant is above -10°C.

[0026] The first po...

Embodiment 2

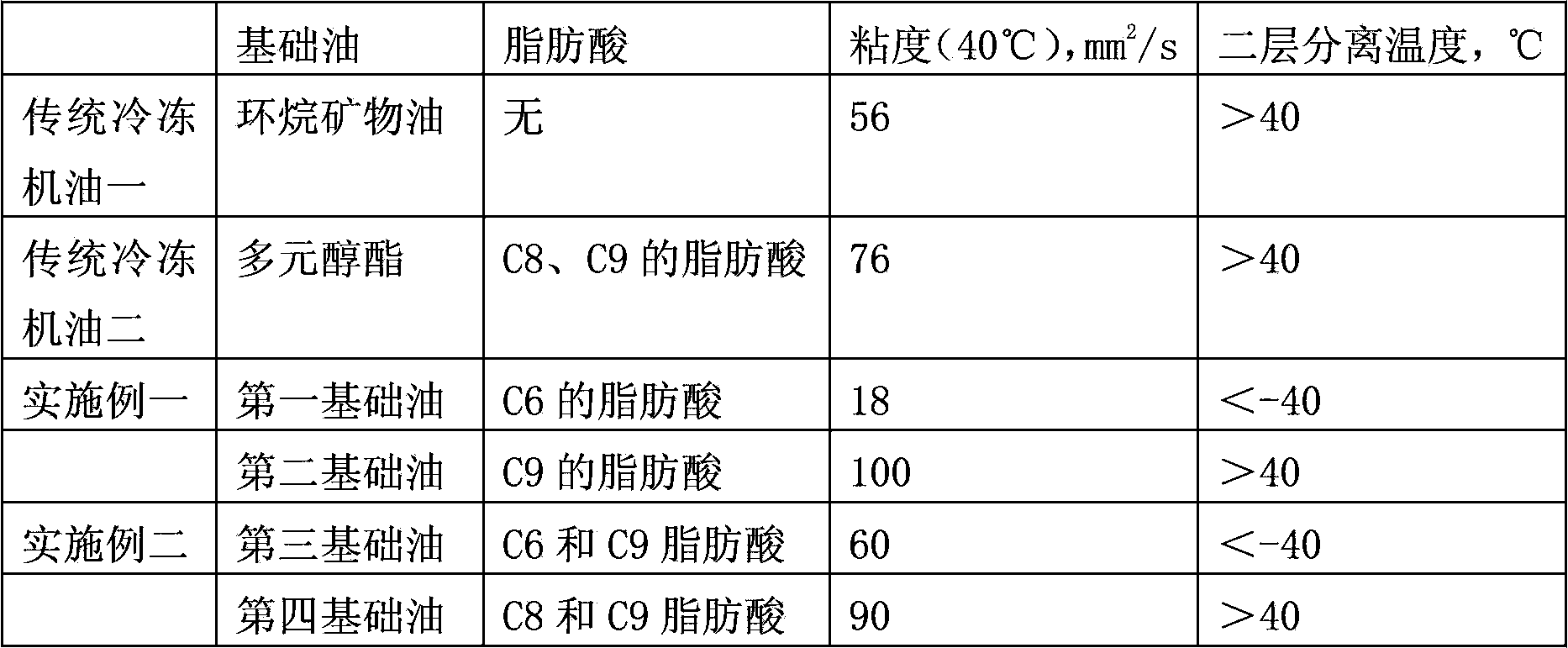

[0033] When the refrigerating machine oil is formed by mixing the third base oil and the fourth base oil, the third base oil adopts the first polyol ester, and R1~R4 in the third base oil are alkanes containing 6 and 9 carbon atoms. base, wherein the molar volume ratio of C6 and C9 is more than 50%; the fourth base oil adopts the second polyol ester, and the R1'~R4' in the fourth base oil are those containing 8 and 9 carbon atoms Alkyl, wherein the molar volume ratio of C8 and C9 is below 50%. The characteristics of the refrigerating machine oil obtained after mixing are shown in Table 1. The viscosity of the refrigerating machine oil at 40°C is 68mm 2 / s, the viscosity in Example 1 is significantly improved, but the two-layer separation temperature is worse than that in Example 1, and the two-layer separation temperature reaches 10°C.

[0034] See Embodiment 1 for the rest of the undescribed parts, and will not repeat.

[0035] Table 2

[0036]

[0037] Table 2 shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com