System and method for on-line control of molten steel temperature in LF refining

A technology of molten steel temperature and refining process, which is applied in the system field of online control of molten steel temperature in LF refining process, and can solve problems such as few temperature models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

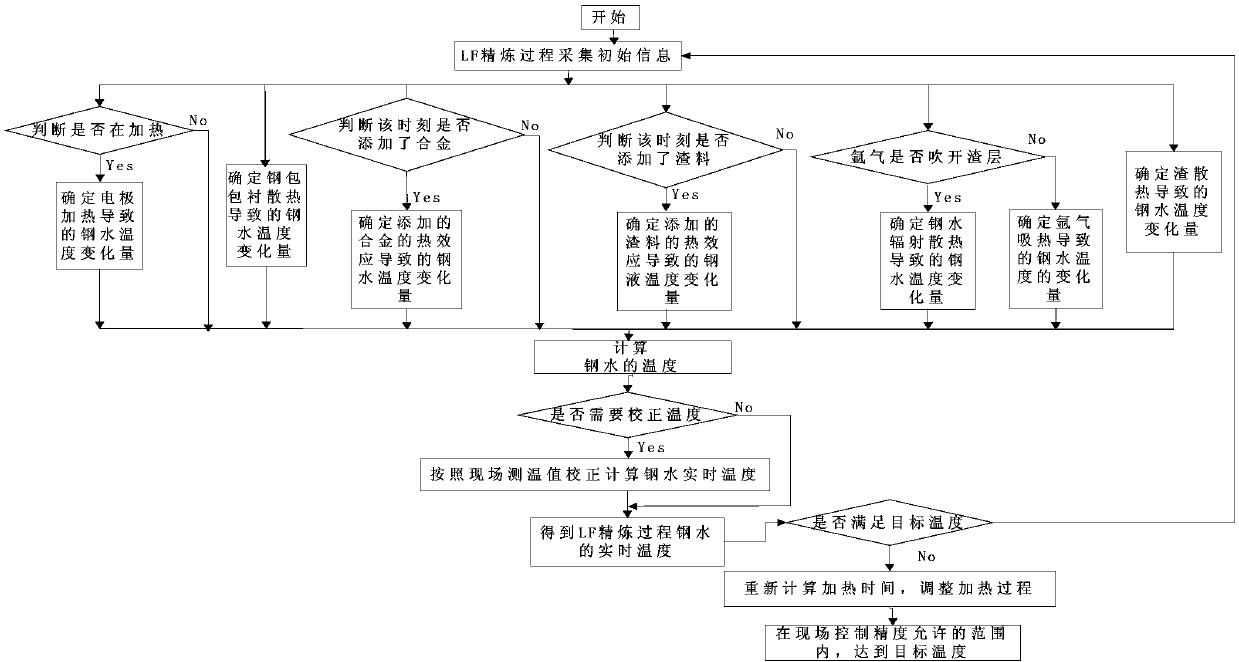

[0069] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

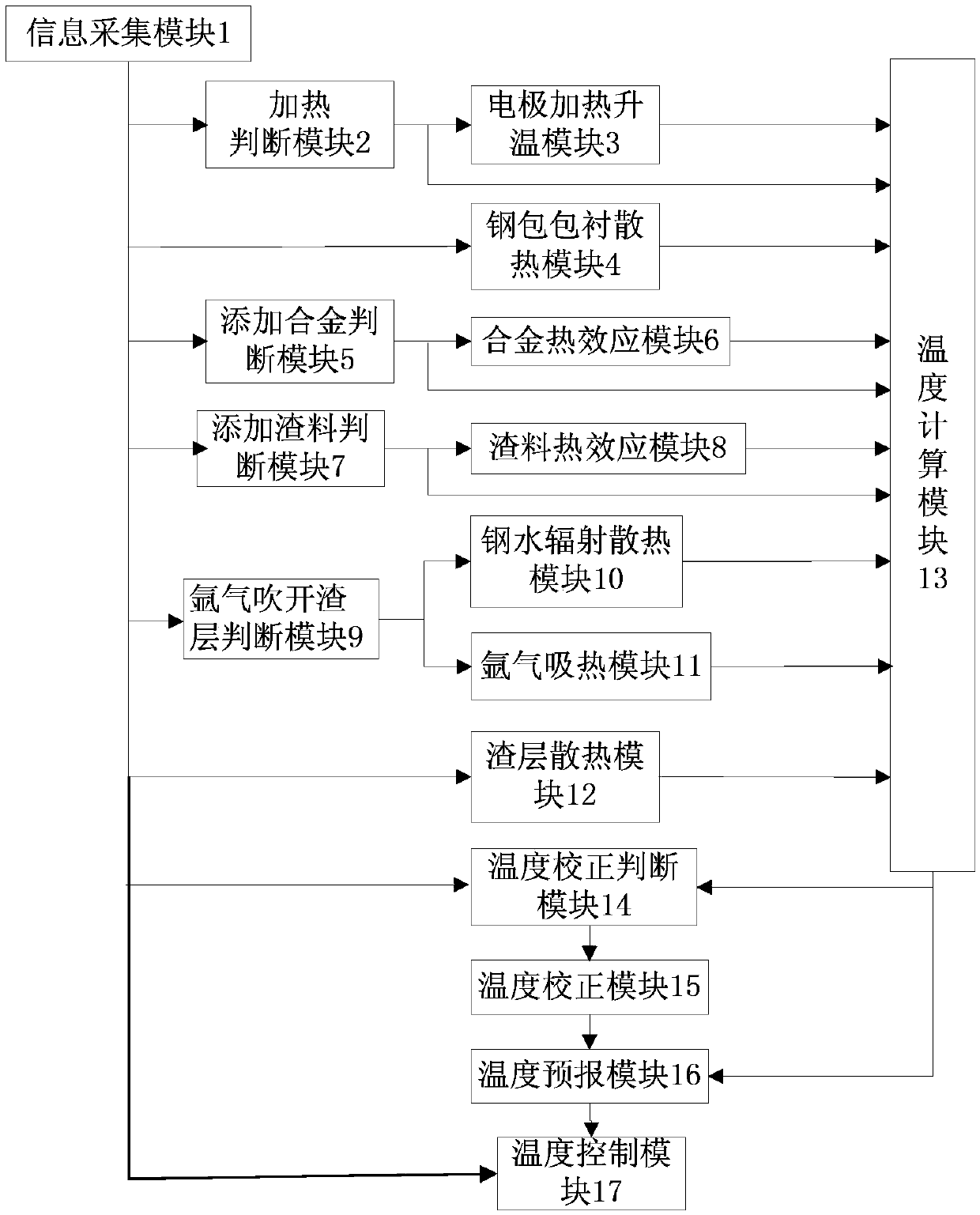

[0070] Such as figure 1 As shown, the system for online control of molten steel temperature in the LF refining process of this embodiment includes:

[0071] Information collection module 1: used to collect the corresponding steel type, furnace number, molten steel weight, slag layer thickness, slag layer surface area, on-site alloy addition amount, alloy entering furnace temperature, on-site slag addition amount, slag Furnace input temperature of material, critical argon amount, real-time bottom blowing argon amount, electrode current value, electrode voltage value, electrode heating gear, electrode heating efficiency, refining start time, refining time, ambient temperature, blowing argon gas The initial temperature of the molten steel, the exposed area of the molten steel by blowing off the slag layer, the heating time set according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com