Lining plate for protecting self-evaporator from wear and corrosion

A technology of self-evaporator and lining plate, applied in the field of new-structure lining plate, can solve the problems of aggravating the stress corrosion cracking tendency of girth welds, intensifying the corrosion of the slurry self-evaporating cylinder, reducing the pressure bearing capacity of the equipment, etc. Stress corrosion susceptibility, easy assembly and welding, and the effect of preventing evaporation and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

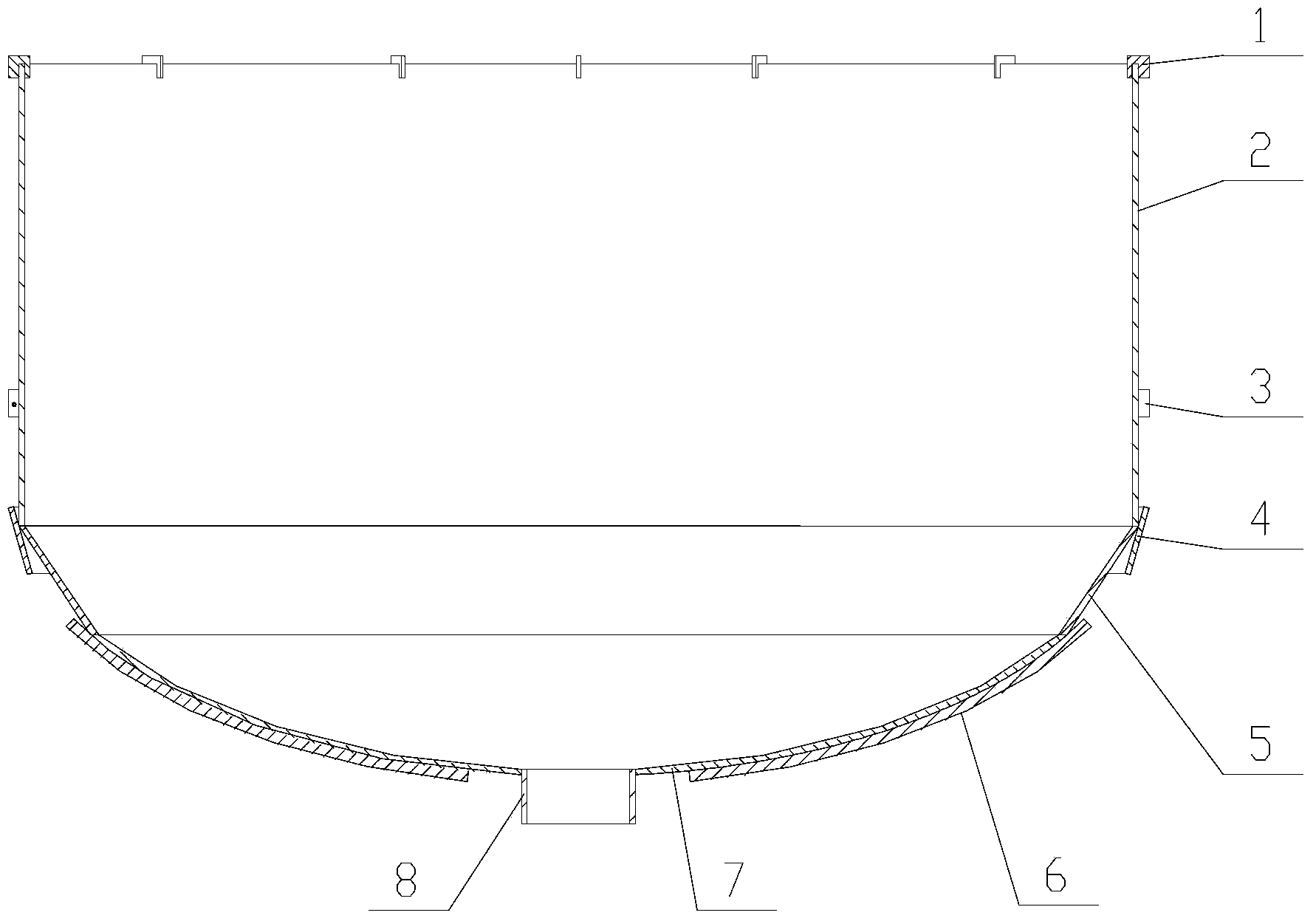

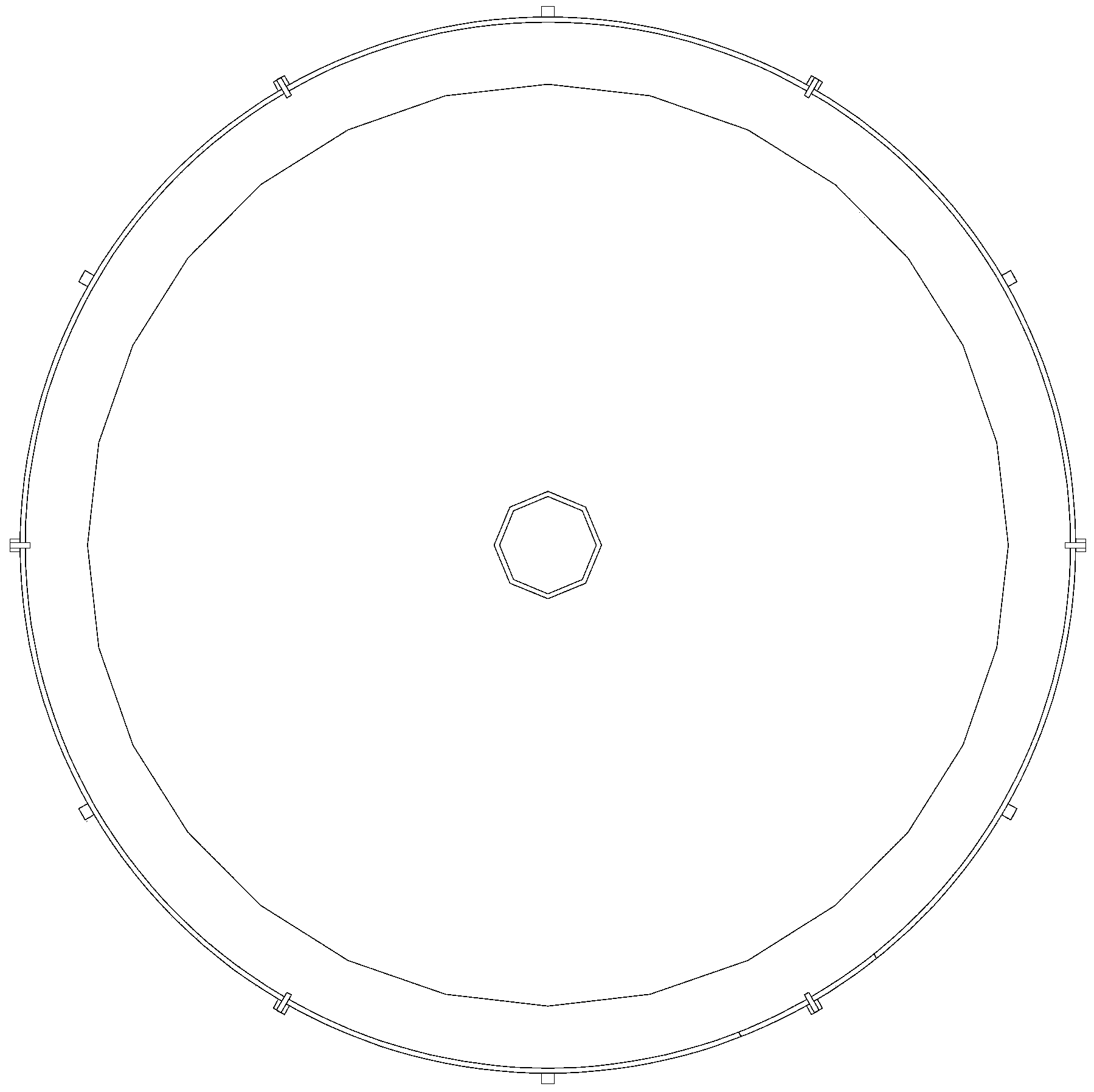

[0009] Such as figure 1 , 2 As shown, the lower end of the cylinder body 2 is welded with the cone section barrel joint 5, the lower end of the cone section barrel section 5 is welded with an elliptical sealing plate 7, and the center of the oval sealing plate 7 is welded with a discharge steel pipe 8; the outer wall of the cylinder body 2 Weld the supporting backing plate 3 on the top, weld the corner backing plate 4 at the outer weld of the cylinder body 2 and the cone segment barrel section 5, and weld the raising backing plate 6 on the outer side wall of the oval sealing plate 7 .

[0010] A U-shaped slot card 1 is fixed on the upper port wall of the cylinder body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com