Plant essential oil formaldehyde remover and preparation method thereof

A formaldehyde remover and plant essential oil technology, applied in the field of bioengineering, can solve the problem that formaldehyde cannot be fundamentally removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

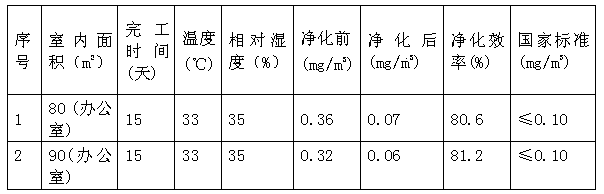

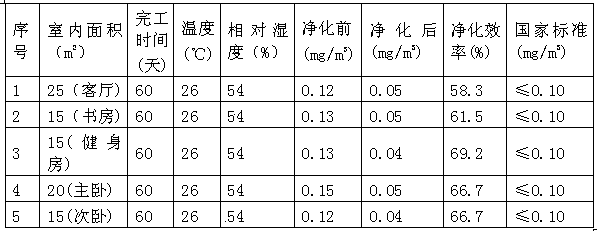

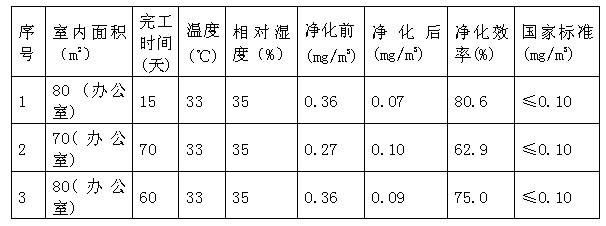

Examples

Embodiment 1

[0016] A plant essential oil formaldehyde remover, made of the following raw materials in parts by weight: 2 parts of mugwort leaf oil, 4 parts of spearmint oil, 4 parts of peppermint oil, 2 parts of eucalyptus oil, 2 parts of artemisia oil, 30 parts of ethanol, 5 parts of glycerin parts, 51 parts of deionized water.

[0017] The preparation method of the plant essential oil formaldehyde remover is to mix the raw materials according to the weight ratio, then put them into a reaction tank for mixed reaction, the reaction temperature is 18°C-40°C, and at the same time, uniformly stir under normal pressure for 25-60 minutes, The obtained plant essential oil formaldehyde remover.

[0018] Purchase mugwort oil, spearmint oil, peppermint oil, eucalyptus oil, and artemisia oil in accordance with national standards, among which ethanol, deionized water, and glycerin are restricted by food-grade standards.

[0019] When in use, the plant essential oil formaldehyde remover is atomized ...

Embodiment 2

[0021] The difference between this embodiment and embodiment 1 is mainly that: a plant essential oil formaldehyde remover is made of the following raw materials in parts by weight: 1.5 parts of mugwort oil, 3 parts of spearmint oil, 3 parts of peppermint oil, 1.5 parts of eucalyptus oil, 1.5 parts of Artemisia annua oil, 25 parts of ethanol, 3 parts of glycerin, 45 parts of deionized water.

Embodiment 3

[0023] The difference between the present embodiment and embodiment 1 mainly lies in: a plant essential oil formaldehyde remover, made of the following raw materials in parts by weight: 2.5 parts of mugwort oil, 5 parts of spearmint oil, 5 parts of peppermint oil, 2.5 parts of eucalyptus oil, Artemisia annua oil 2.5 parts, ethanol 35 parts, glycerin 7 parts, deionized water 58 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com