Method for casting piston ring by use of iron type sand coating cylinder

A sand-coated iron mold and piston casting technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of large blank machining allowance and heavy cleaning workload of castings, and achieve good overall surface quality and clean work. Small amount, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it according to the description. The protection scope of the present invention is not limited to the specific embodiments of the present invention.

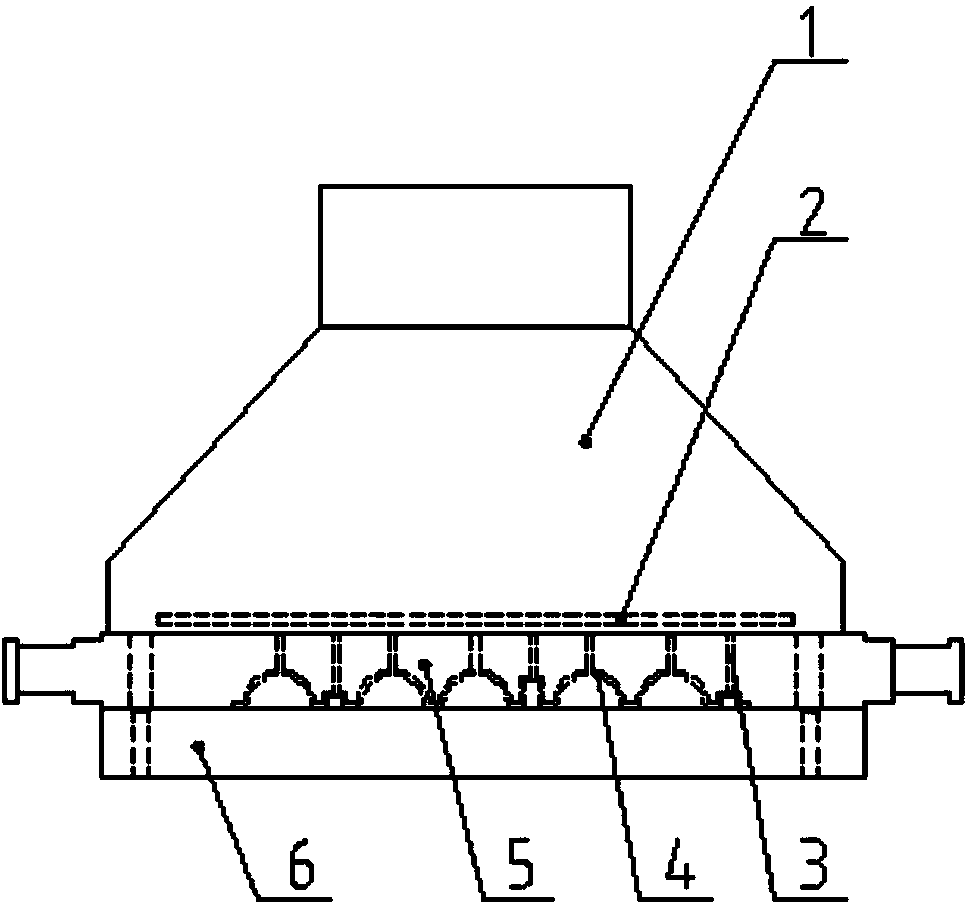

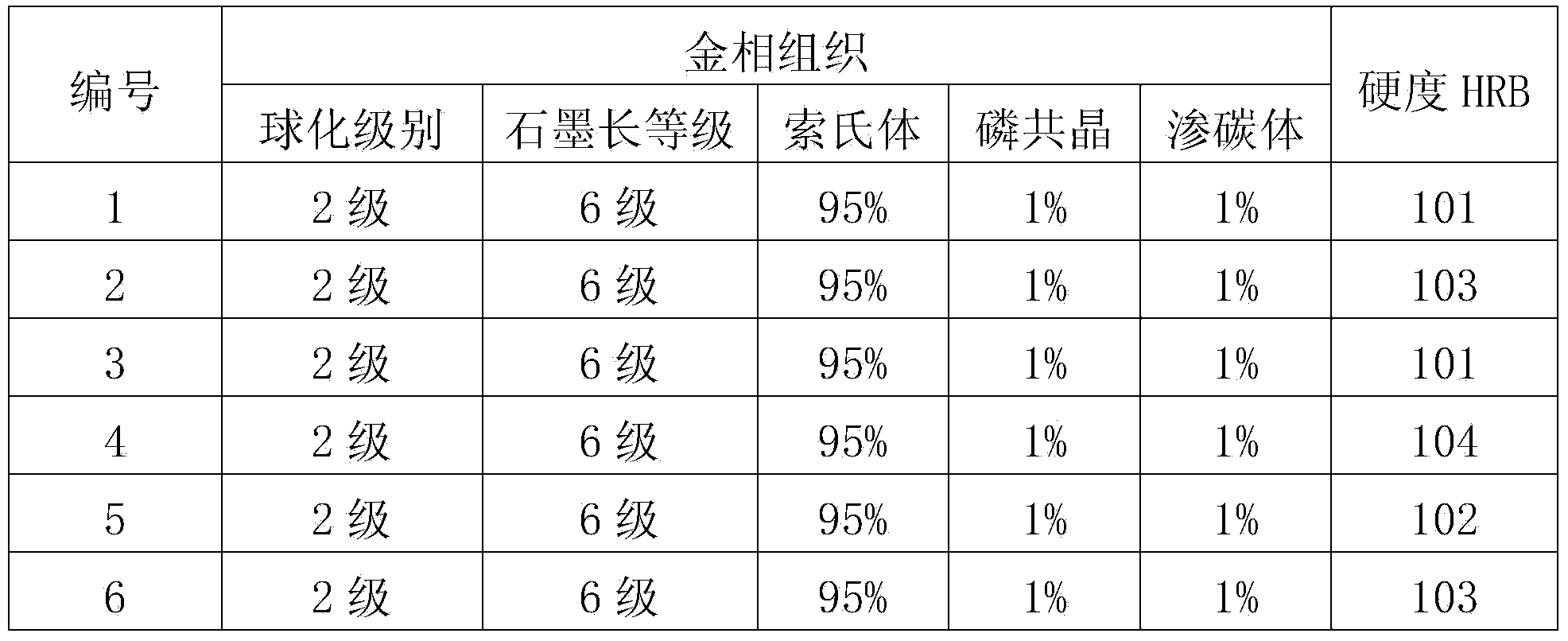

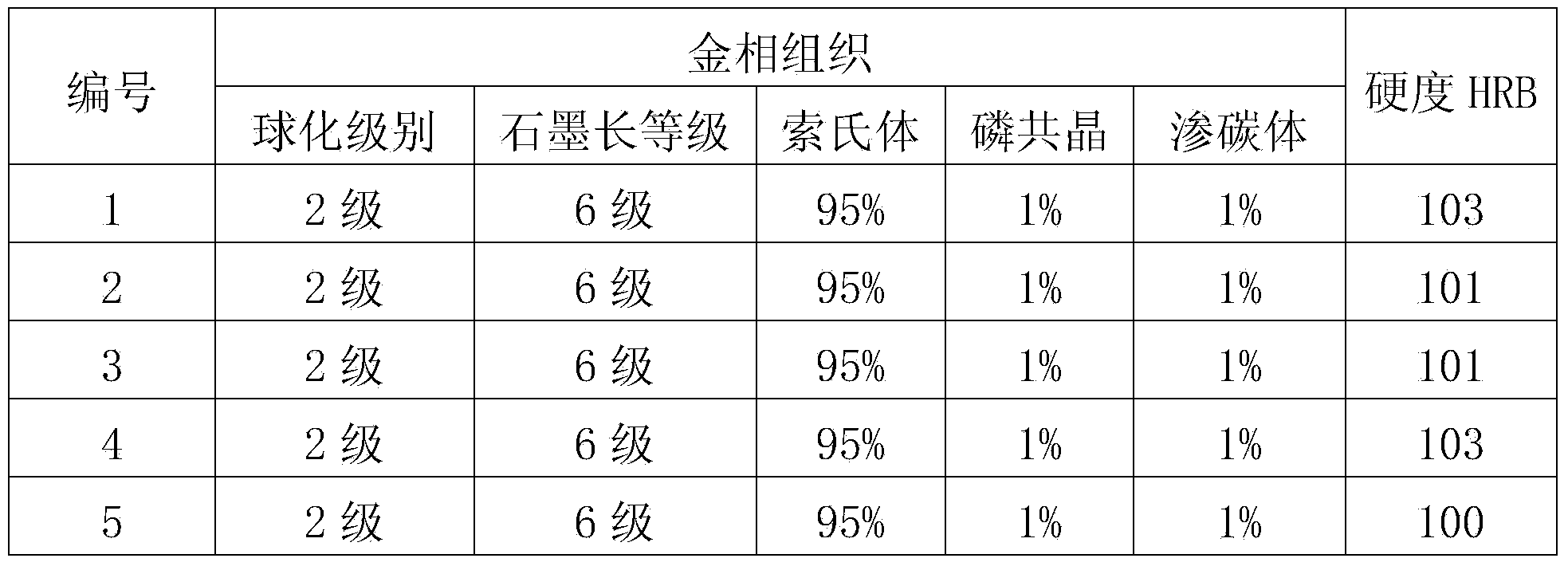

[0022] The invention discloses a method for casting a piston ring with an iron-type sand-covered cylindrical body. The technological steps include: mold manufacturing, molding, core setting, box closing, pouring, box opening, casting cleaning and machining. Produce piston rings with a specification of Φ105mm according to the above process steps, and conduct corresponding inspections on castings and finished piston rings.

[0023] 1. Mold manufacturing

[0024] The mold plate 6 is manufactured according to the cylinder blank of the piston ring, the plate 6 is divided into upper and lower plates, the upper and lower plates are symmetrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com