Sealing apparatus for end faces of rotary drum

An end-face sealing and drum technology, which is used in engine sealing, dehydration/drying/concentrated sludge treatment, engine components, etc. The effect of increasing friction, preventing side leakage and preventing the deviation of the filter belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

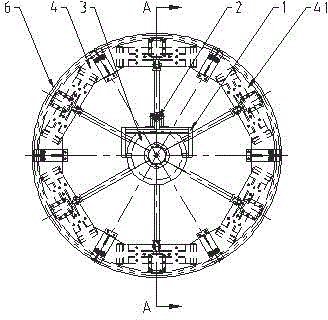

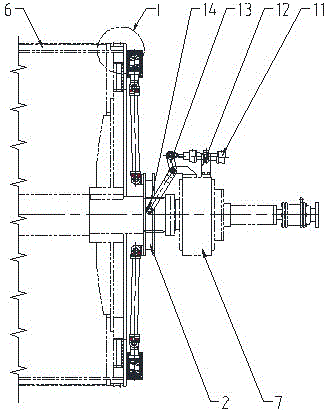

[0020] as attached Figure 1-4 As shown, the present invention is a drum end face sealing device, which is composed of a pull rod mechanism 1 , a sliding sleeve 2 , a pressure rod mechanism 3 , a sealing end plate 4 and a labyrinth seal 5 . Among them, the central drum 6, the supporting bearing seat 7, the pressure roller 8 and the filter belt 9 are the upstream and downstream process-related equipment.

[0021] The pull rod mechanism 1 is fixed on the support bearing seats 7 on both sides of the central drum 6 and drives the entire sealing device to move; the sliding sleeve 2 is installed on the central rotating shaft of the central drum 6; the pressure rod mechanism 3 and the seal The end plates 4 are installed on both sides of the central drum 6 and unfolded to form a ring-shaped sealing surface during operation; the labyrinth seal 5 is formed by processing and assembling both ends of the central drum 6 and pressure roller 8 .

[0022] The pull rod mechanism 1 includes a d...

Embodiment 2

[0028] The basic structure and method of use are the same as in Example 1 in this example.

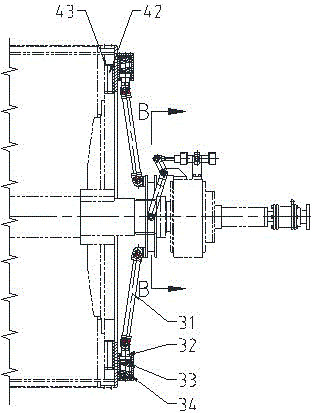

[0029] like figure 2 As shown, the drive cylinder 11 is retracted, the Y-shaped tie rod 13 and the support bearing seat 7 move the bifurcated end of the Y-shaped tie rod 13 to the left through the principle of leverage, and the two guide wheels 14 push the sliding sleeve 2 to move axially to the left. The guide wheel 14 and the connecting rod 31 are connected by a hinge, and the connecting rod 31 transmits the action to the slide plate 42 through the spring 33 in the spring slide plug 32 and the spring sliding sleeve 34, so that the slide plate 42 radially protrudes, and there are 6 slide plates 42 , the sealing plate 41 on the slide plate 42 forms a complete seal on the end face of the central drum 6 .

[0030] like Figure 4 As shown, in the present invention, the central drum surface labyrinth 51 and the pressure roller surface labyrinth 52 on the edge of the central drum 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com