Preparation method of imidazole functionalized amphiphilic periodic mesoporous organic silicon material

A mesoporous organosilicon and functionalization technology, which is applied in chemical instruments and methods, organic chemistry, compounds of group 4/14 elements of the periodic table, etc., can solve the problem of less morphology and achieve simple steps and good morphology , high regularity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

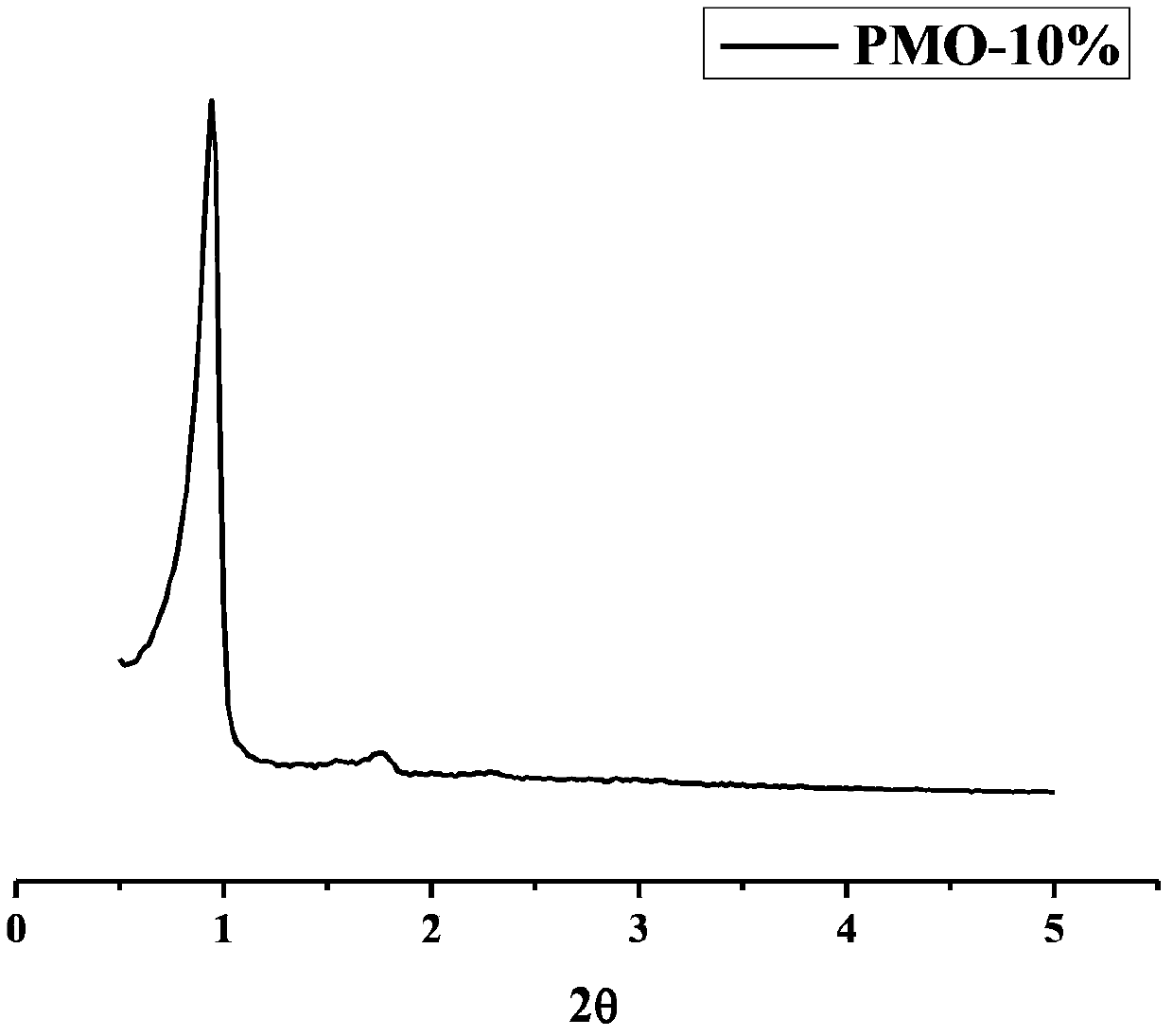

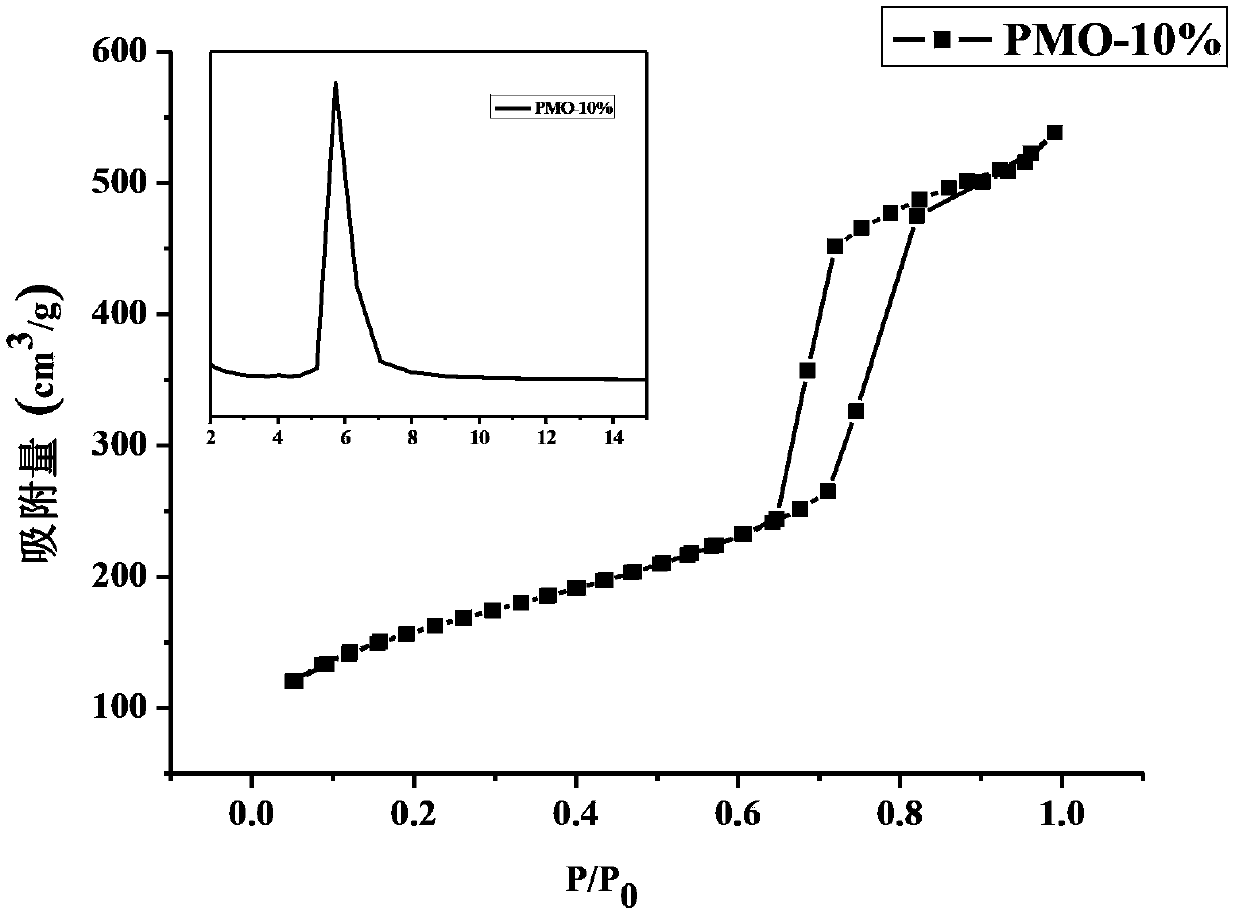

[0032] Example 1: Material containing 10% functionalized imidazole silicon source and BTEE copolymerization

[0033] (1) Weigh 2.5g of 1-vinylimidazole into a 100mL round bottom flask, use 50mL of toluene as solvent, stir at 1000rmp at 0°C until completely dissolved; dissolve 3.5g of 1,3-propane sultone in 15mL of toluene , slowly added dropwise to the round bottom flask of step (1) at 0°C, and the dropwise addition was completed in 10 minutes. After 30 minutes at 0°C, the temperature was raised to 40°C at a rate of 8°C / min, and the reaction was maintained at 1000rmp for 5 days, and the pressure was reduced. After filtration, it was washed with anhydrous ether (20mL×3) to obtain a highly deliquescent white solid, which was dried under vacuum at 50°C for 12h. The product quality is 5.28g, and the yield is 63.4%. The white solid obtained is dissolved in a 25mL round-bottomed flask with 2mL of water, and the mass concentration of 98% concentrated sulfuric acid is slowly added dro...

Embodiment 2

[0039] Example 2: Material containing 20% functionalized imidazole silicon source and BTEE copolymerized

[0040] Step (1) of this embodiment is the same as that of Embodiment 1.

[0041] (2) This step is basically the same as step (2) of Example 1, except that the dark red liquid obtained in the added step (1) is 1.257g, triethoxysilane is 0.57mL, and Kmarstedt catalyst is 0.15mL . The mass of the obtained brown viscous liquid was 1.835 g.

[0042] (3) This step is basically the same as step (3) of Example 1, except that the weight of the brown viscous liquid obtained in the added step (2) is 1.835g, and the amount of BTEE is 3mL; the quality of the obtained product is 6.096g .

[0043] (4) Same as step (4) of Example 1. The resulting product mass was 5.481 g.

[0044] from Figure 5 It can be seen in the d 100 There is a strong diffraction peak at d 110 and d 200 A weak diffraction peak at , indicates that the material has an ordered two-dimensional hexagonal meso...

Embodiment 3

[0046] Example 3: Material containing 30% functionalized imidazole silicon source and BTEE copolymerization

[0047] Step (1) of this embodiment is the same as that of Embodiment 1.

[0048] (2) This step is basically the same as step (2) of Example 1, except that the dark red liquid obtained in the added step (1) is 1.886g, triethoxysilane is 0.86mL, and Kmarstedt catalyst is 0.25mL . The mass of the obtained brown viscous liquid was 2.697g.

[0049] (3) This step is basically the same as step (3) of Example 1, except that the weight of the brown viscous liquid obtained in the added step (2) is 2.697g, the amount of BTEE is 2.6mL, and the time for dropping is 10min; The resulting product mass was 6.337 g.

[0050] (4) Same as step (4) of Example 1. The resulting product mass was 5.883 g.

[0051] from Figure 8 It can be seen in the d 100 There is a strong diffraction peak at d 110 and d 200 A weak diffraction peak at , indicates that the material has an ordered two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com