Spinning slurry discharge circulation pipeline system

A technology for sizing and spinning, applied in the field of spinning sizing and sizing circulation pipeline system, can solve the problems of consuming manpower, material resources, affecting physical health, reducing work efficiency, etc., achieving high driving speed, reducing driving labor intensity, and improving work The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

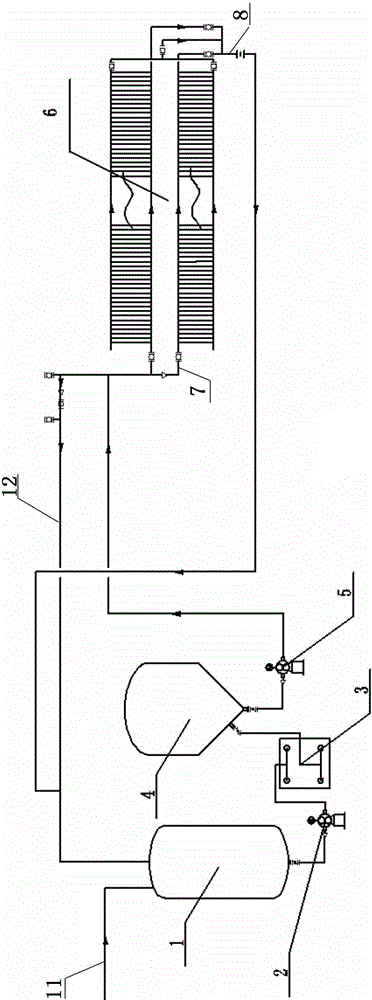

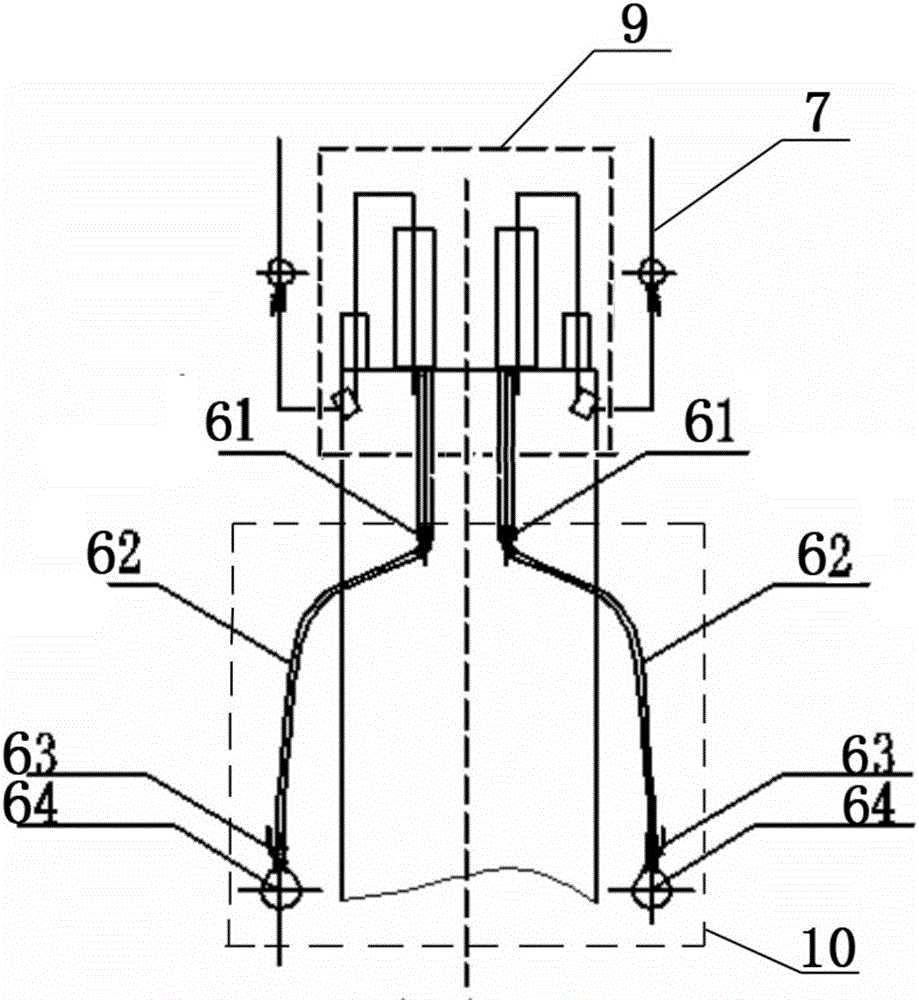

[0016] The following combination figure 1 and figure 2 The mold structure shown illustrates the specific implementation process of the present invention.

[0017] figure 1 In the spinning slurry discharge circulation pipeline system, the slurry made from the dissolving tank is communicated with the upper part of the slurry filter feed tank 1 through the pipeline 11, and the lower part of the slurry filter feed tank 1 passes through the pipeline and the filter delivery pump 2 It communicates with the inlet of the plate and frame filter 3. The degassing tank 4 is a sealed body composed of an upper cylinder and a lower cone. The outlet of the plate and frame filter 3 is connected to the side wall of the lower cone of the degassing tank 4 through a pipeline, and the bottom of the lower cone is connected to the spinning slurry pump 5 through a pipeline. It is communicated with the inlet pipeline of the pulping mechanism 6 of the spinning machine, and the outlet of the pulping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com