Self-drilling RCA (recycling composite anchor) rod and construction method thereof

A bolt construction and self-drilling technology, which is applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems such as the difficult realization of bolt rotation and other movement modes, the low bearing capacity of bolts, and the difficulty of popularization, etc., to achieve installation And recycling construction is fast and convenient, improving the pull-out bearing capacity, and the effect of environmental protection is outstanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

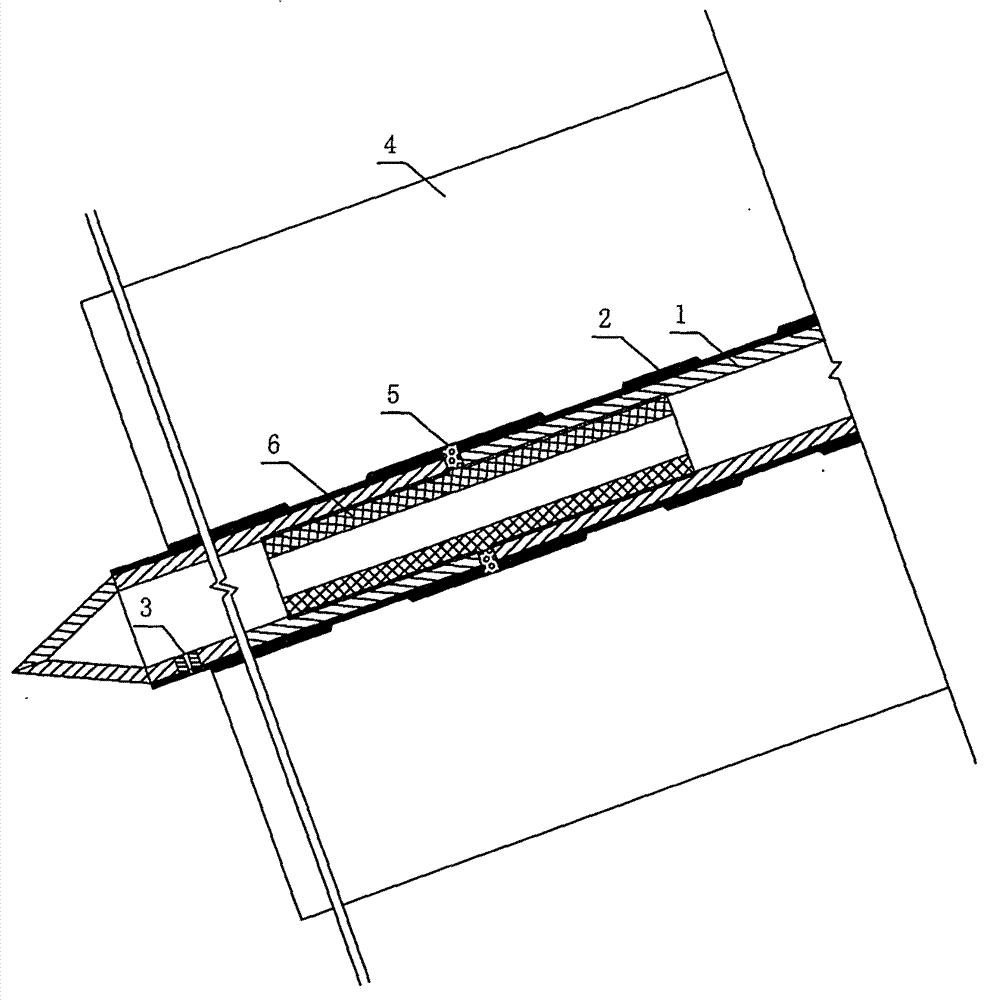

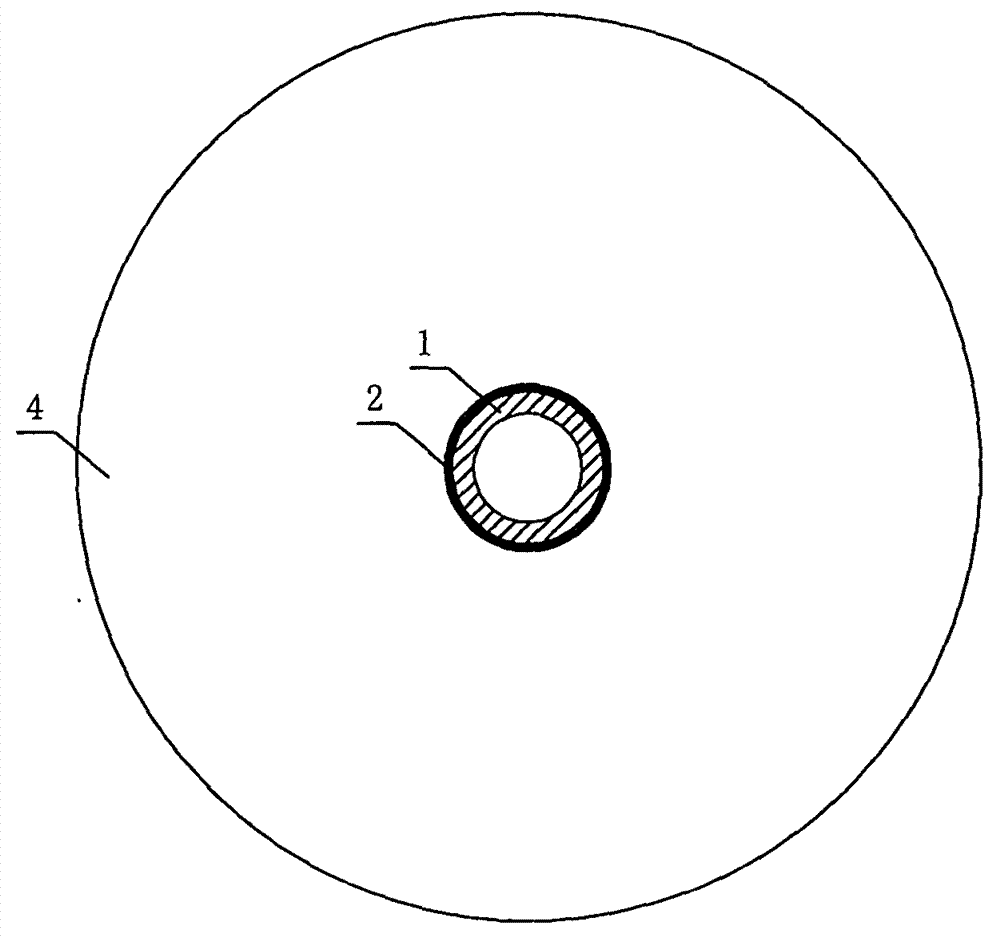

[0022] As the present invention such as figure 1 and figure 2 The main purpose of the illustrated embodiment is to introduce the structure, working principle and installation and recovery construction method of the self-drilling RCA retrievable bolt. Such as figure 1 and figure 2As shown, the self-drilling RCA retrievable rock bolt of the present invention includes four parts: a hollow drill pipe (1), a hot-melt power transmission belt (2), a high-pressure nozzle (3), and a high-pressure jet grouting pile anchor (4). Among them, the high-pressure jet grouting pile anchor (4) is the part that is connected with the soil to provide the uplift bearing capacity, and the hollow drill pipe (1) is connected with the high-pressure jet grouting pile anchor (4) through the heat-melting force transmission belt (2). ) is firmly connected to the structure that transfers the pullout bearing capacity of the anchor rod, and the hot-melt force transfer belt (2) is a structure wrapped aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com