Physical simulation test system for true triaxial rockburst of deep-buried tunnel

A technology of physical simulation and test system, applied in the field of true triaxial rockburst physical simulation test system, can solve the problem of low loading capacity, affecting the accuracy and reliability of experimental results, and unable to provide a large enough load to simulate deep-buried rock mass highlands Stress state and other issues, to achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see Attachment

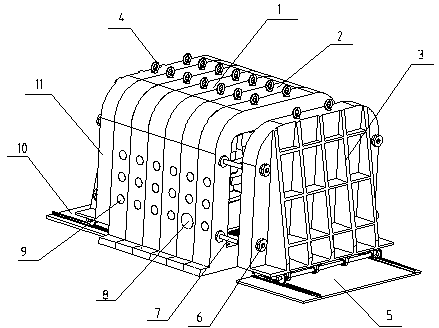

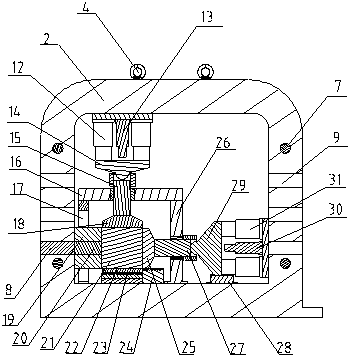

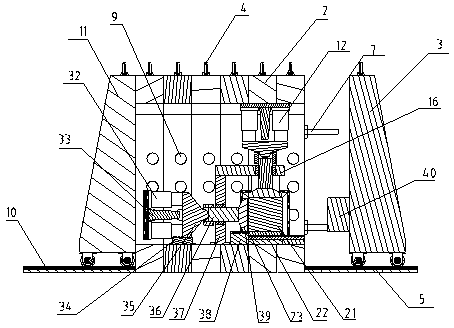

[0034]A true triaxial rockburst physical simulation test system for deeply buried tunnels. The true triaxial rockburst physical simulation test system consists of a reaction frame 1, a vertical loading system 12, a horizontal front and rear loading system 32, and a horizontal left and right loading system. The system 31 is composed of a true three-axis loading system. The vertical loading system 12, the horizontal front and rear loading system 32 and the horizontal left and right loading system 31 all adopt the Chinese patent application publication number CN102636386A, the publication date is 2012.8.15, and the invention name is "Large Tonnage Uniform-Centralized Loading System" loading system. The reaction frame 1 is formed by connecting and combining two or more steel beam frames 2, front door 3, and rear door 11 through pull rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com