Tobacco cutter outage rate calculation system based on real-time database

A computing system and data storage system technology, which is applied in the field of automatic collection and downtime rate calculation, can solve the problems of not being able to truly reflect the production and operation of equipment, the downtime rate is not objective, and the accuracy rate is not high, so as to achieve high accuracy rate and low workload. The effect of a small, reliable data base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

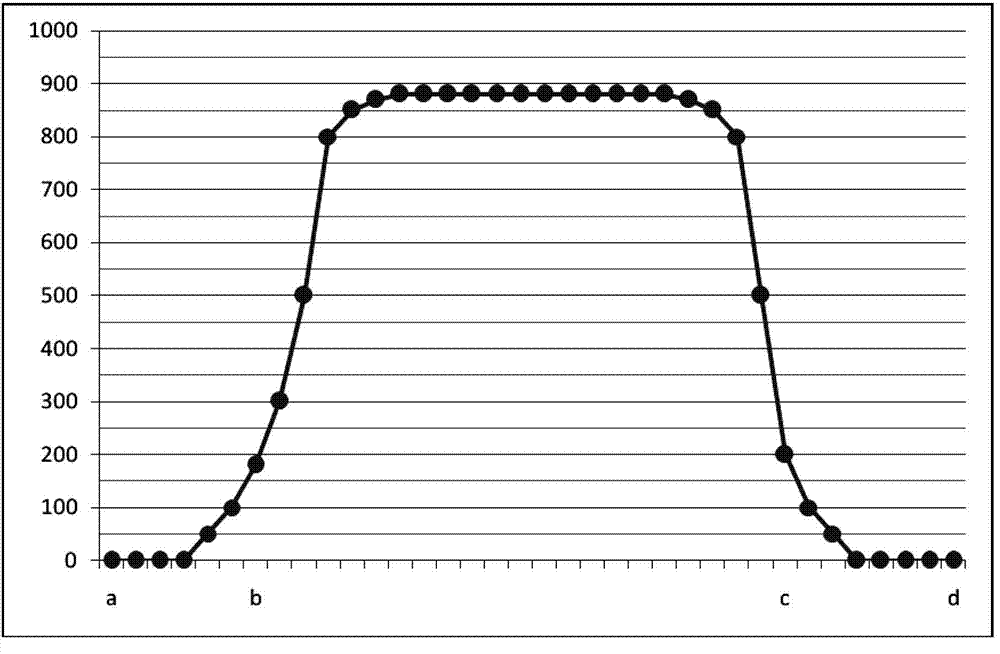

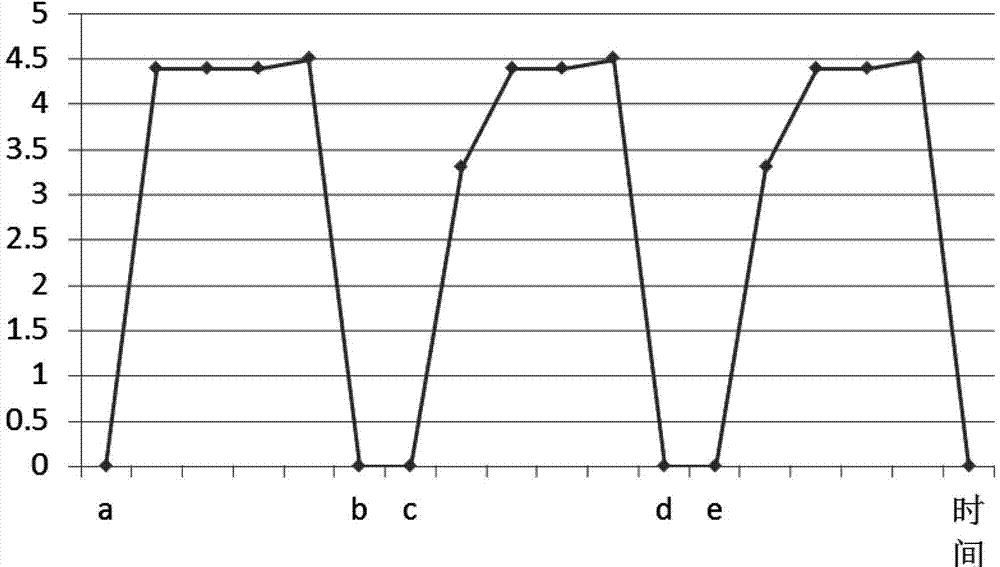

[0021] A silk-making equipment shutdown rate calculation system based on a real-time database. The system includes a data acquisition system, a data storage system, and a data analysis and calculation system. The present invention is equipped with a belt conveyor in each process section of the silk-making workshop and is installed at the entrance With the electronic belt scale, the data acquisition system collects the instantaneous flow rate of the electronic belt scale, and stores the instantaneous flow into the data storage system. The data storage system uses a real-time database. The data analysis and calculation system retrieves the data from the real-time database and stops the machine in the following ways Rate calculation:

[0022] 1. Equipment running time

[0023] Equipment running time = end time of incoming material-start time of incoming material;

[0024] Silk production is organized in the form of work orders. The start time and end time of each work order are recorde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com