AMOLED direct electric signal mixing feedback circuit and driving method thereof

A technology of mixed feedback and driving methods, applied in instruments, static indicators, etc., can solve the problems of slow speed, inaccurate OLED current, complex pixel circuit, etc., to reduce complexity, ensure accuracy, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

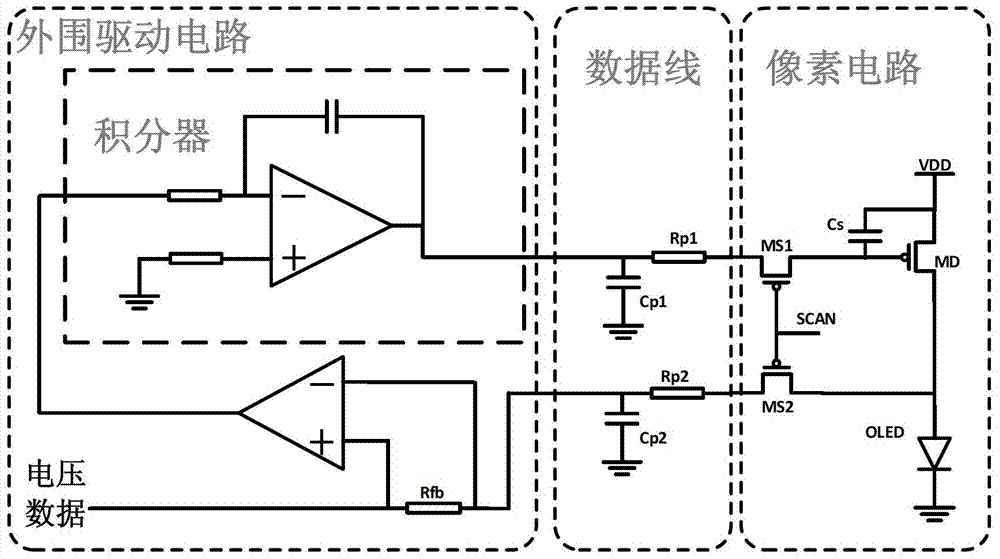

[0032] The present invention does not consider the imperfection of the voltage-controlled current source (VCCS) in the pixel circuit, directly calibrates the voltage at one end of the OLED, and corrects the input voltage of the voltage-controlled current source (VCCS) by the feedback system to make the output current meet the requirements.

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

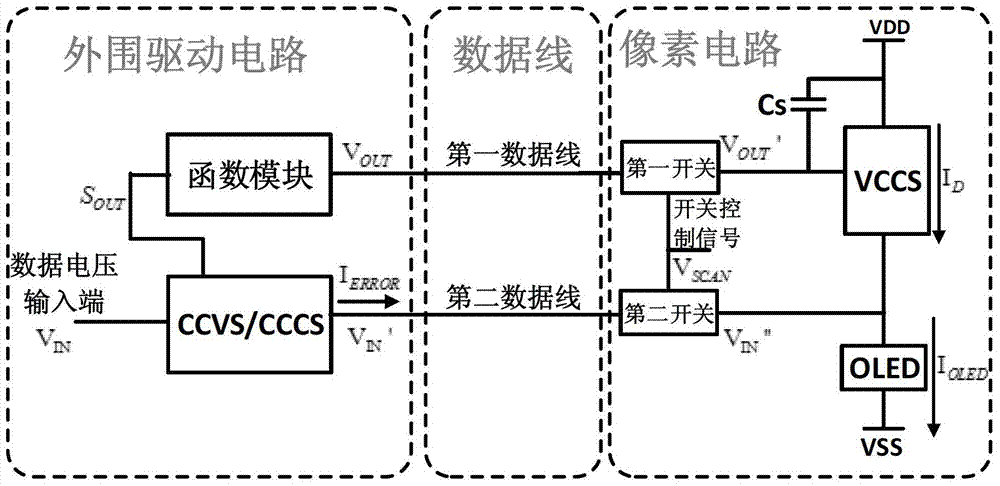

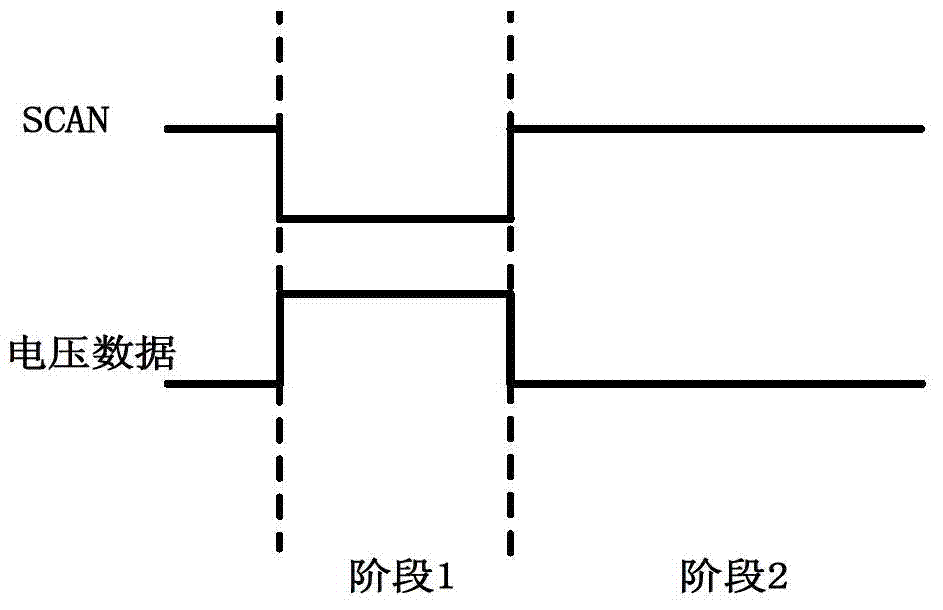

[0034] see figure 1The structure diagram of the present invention shows that the AMOLED direct electrical signal mixing feedback circuit includes a pixel circuit, a peripheral driving circuit and a data line. The pixel circuit refers to the circuit included in each pixel of the AMOLED, and its main function is to provide a stable current for the organic light-emitting diode (OLED) in the pixel circuit; the peripheral drive circuit refers to the circuit in the pixel circuit The main function of the external circuit is to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com