Piston for an internal combustion engine

A technology for internal combustion engines and pistons, applied in the field of internal combustion engine pistons, to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

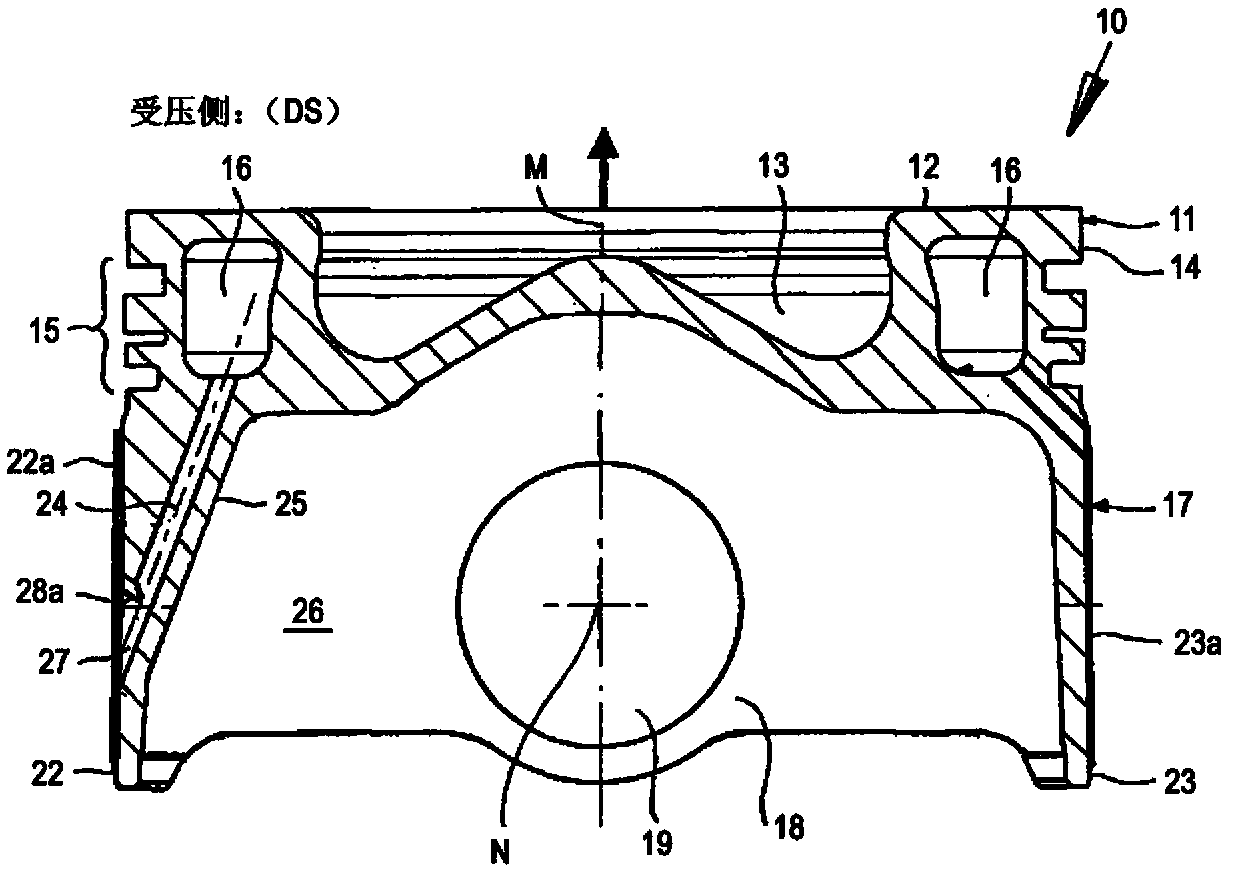

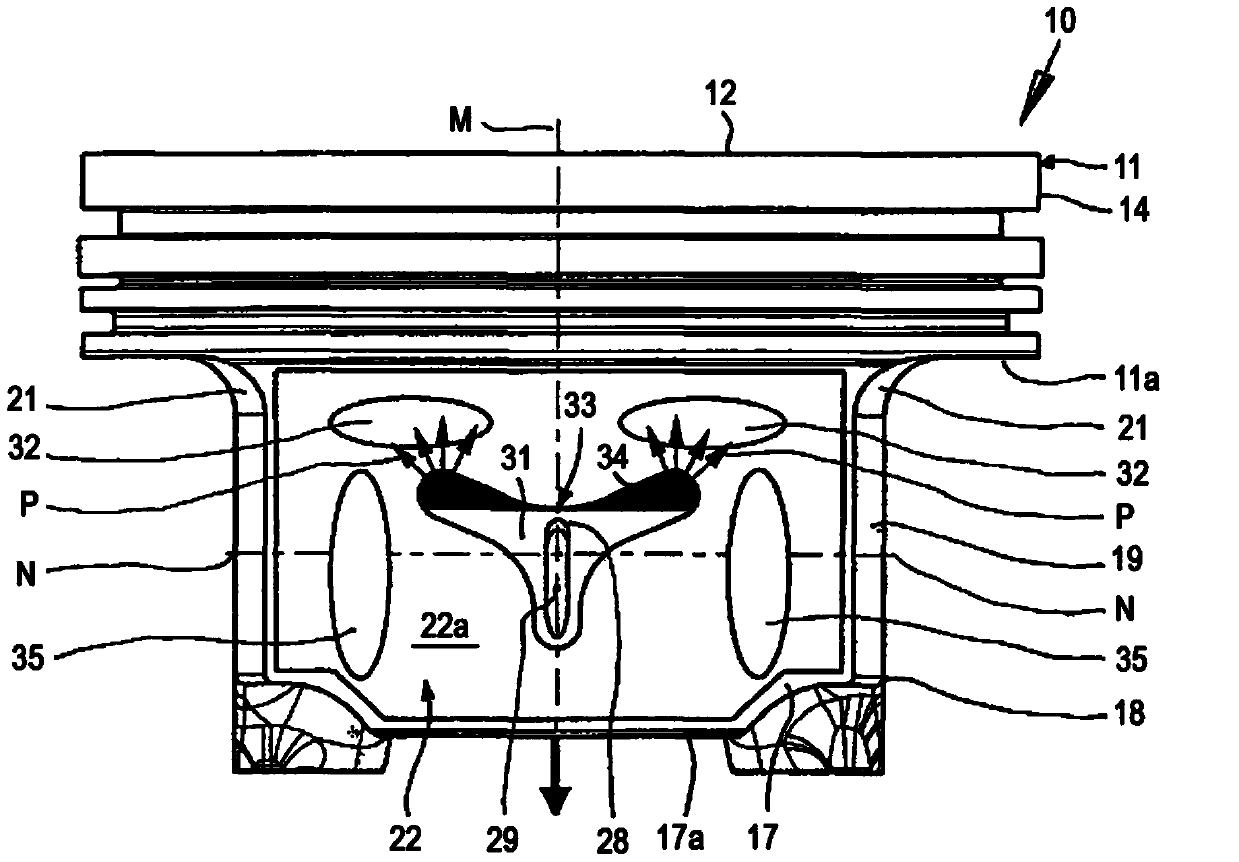

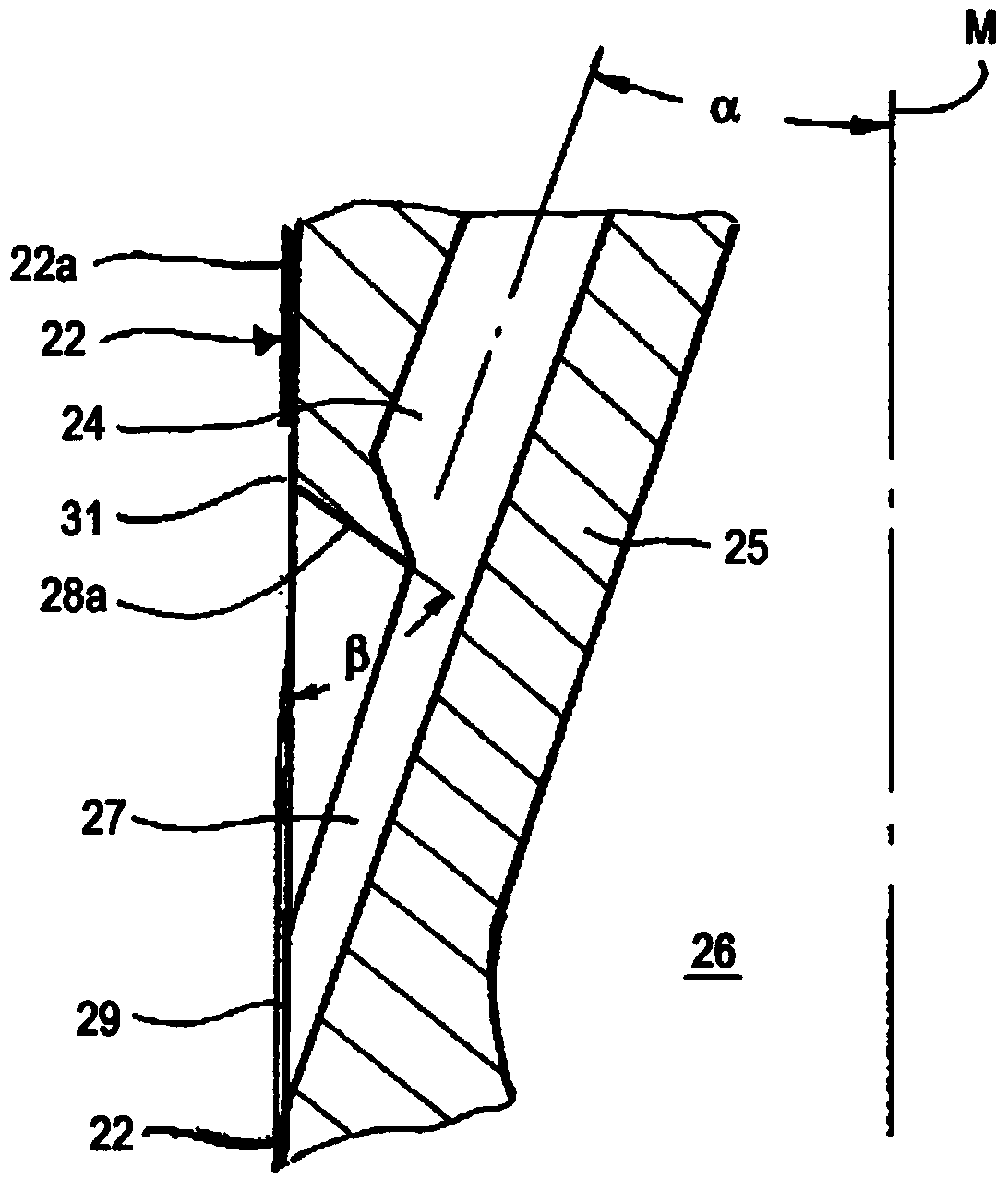

[0028] Figures 1 to 3 A first embodiment of a piston 10 according to the invention is shown. Piston 10 may be a one-piece piston or a piston consisting of several parts. Piston 10 can be made of steel and / or light metal material. Figures 1 to 3 A one-piece box piston 10 is shown as an example. The piston 10 has a piston head 11 with a piston crown 12 , a surrounding crown land 14 and a piston ring section 15 for receiving piston rings (not shown), the piston crown having a crown recess 13 . A circumferential cooling channel 16 is provided at the level of the piston ring part 15 . Furthermore, the piston 10 has a piston skirt 17 with a pin hub 18 and a hub bore 19 for receiving a piston pin (not shown). The pin boss 18 is connected to the underside 11 a of the piston head 11 via a pin boss connection 21 . The pin hubs 17 are connected to each other via working faces 22 , 23 . In this case the working surface 22 corresponds to the pressure side DS of the piston 10 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com