Ceramic multilayered substrate and manufacturing method for same

A multi-layer substrate, ceramic substrate technology, applied in the direction of multi-layer circuit manufacturing, ceramic layered products, printed circuit manufacturing, etc., can solve the problem of difficult to prevent sudden local exudation or splashing, etc., to achieve high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] [Structure of Ceramic Multilayer Substrate]

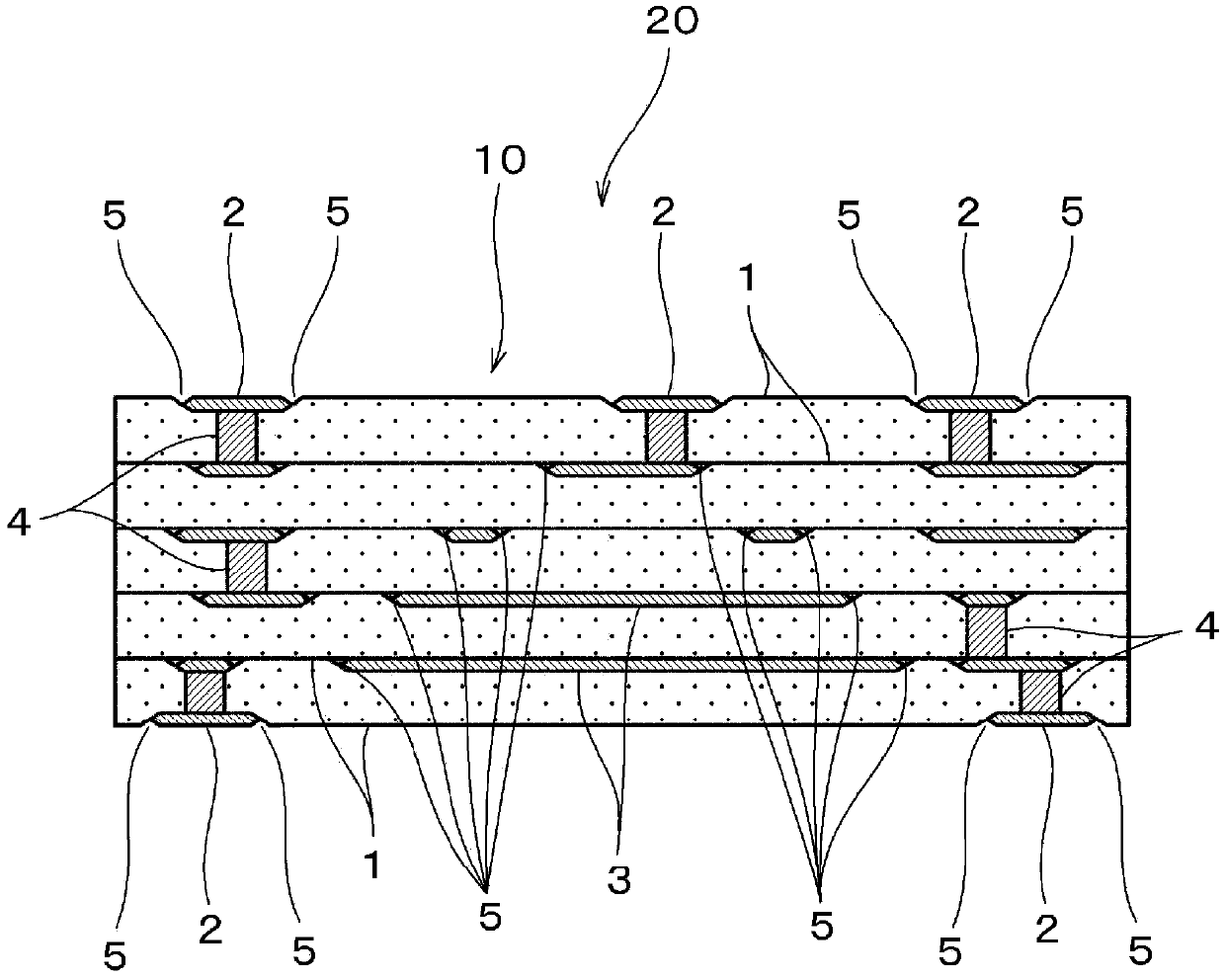

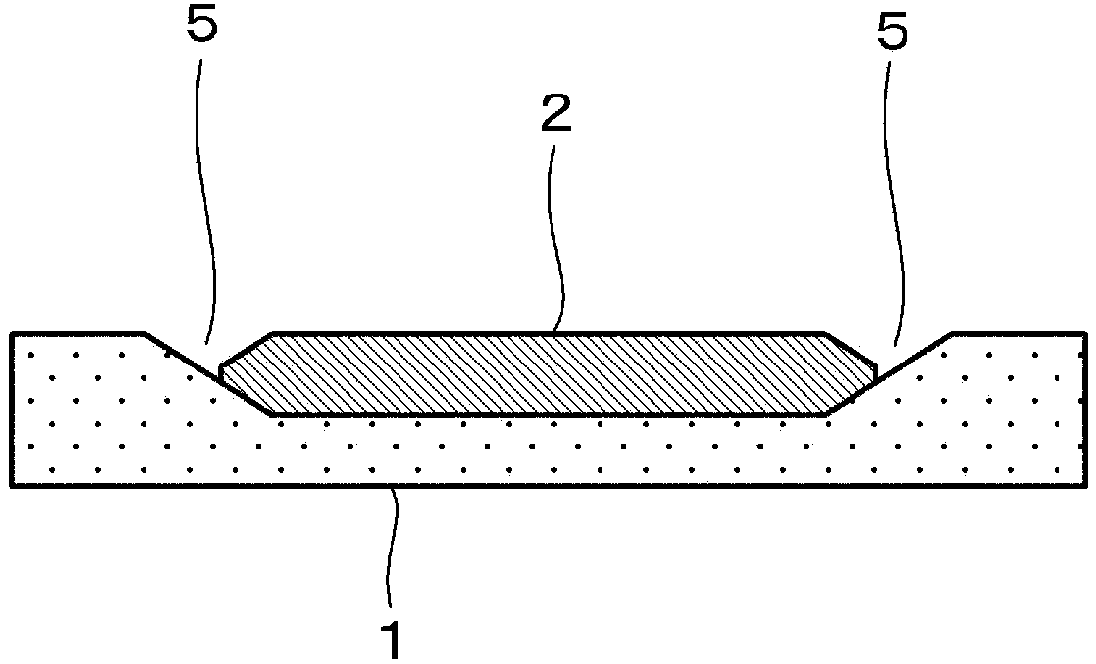

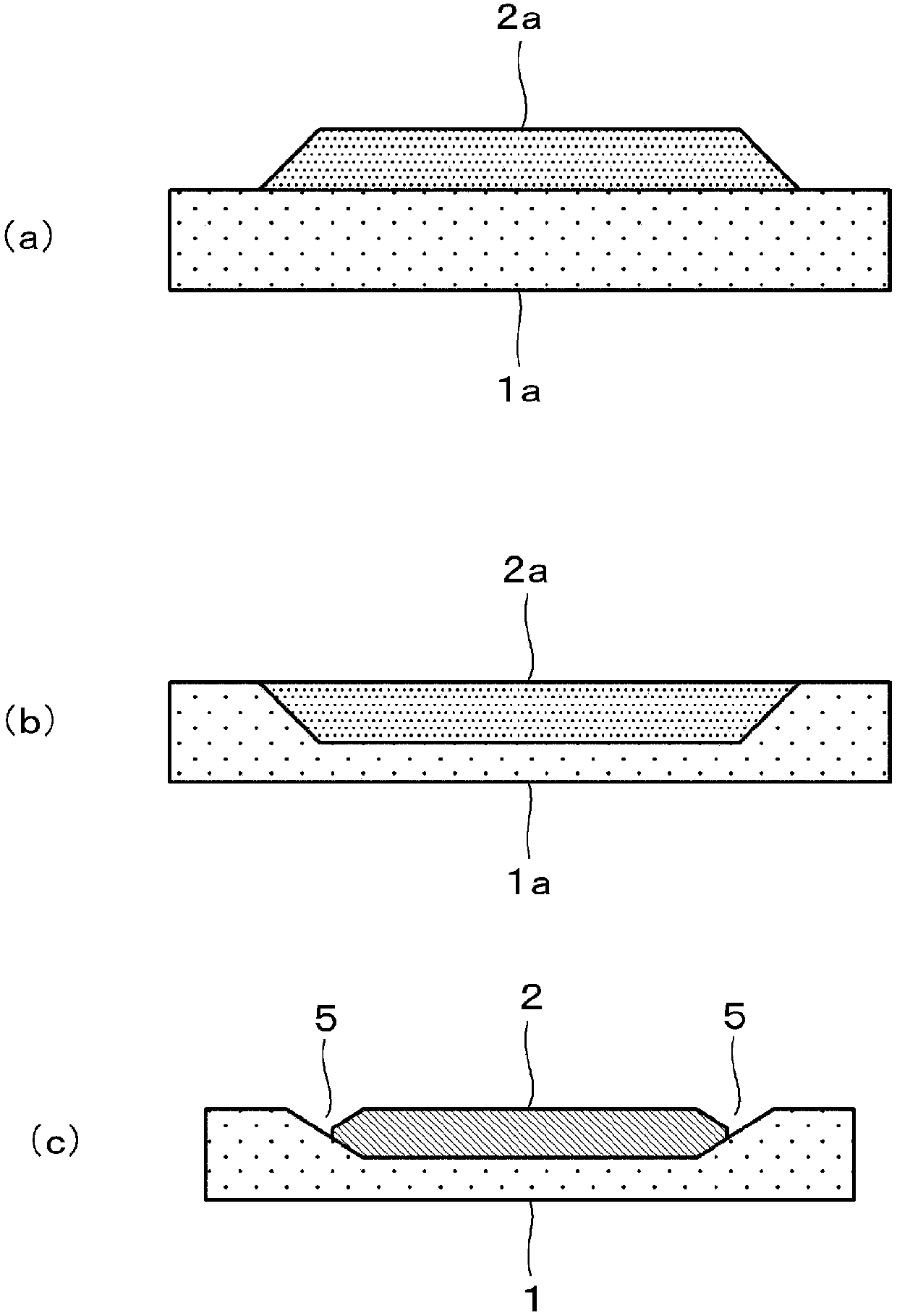

[0055] figure 1 is a cross-sectional view schematically showing the overall structure of the ceramic multilayer substrate 20 according to the embodiment of the present invention, figure 2 is a cross-sectional view showing its main parts.

[0056] The ceramic multilayer substrate 20 according to the first embodiment is a ceramic multilayer substrate mounted on a mounting substrate, and includes a ceramic substrate 10 having a structure formed by laminating a plurality of ceramic layers (base ceramic layers) 1 . The surface electrode 2 is arranged on the ceramic layer 1 constituting the outermost layer of the ceramic substrate; and the internal electrode 3 is arranged on a predetermined ceramic layer 1 . In addition, predetermined portions of the surface electrodes 2 and the internal electrodes 3 are interlayer-connected via via-hole conductors 4 .

[0057] Also, in this ceramic multilayer substrate 20, as figure 1 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap