Resistant malt dextrin and preparation method thereof

A technology of resistant maltodextrin and baking dextrin, applied in the directions of food preparation, application, food science, etc., can solve the problem of less resistant maltodextrin products, and achieve the effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

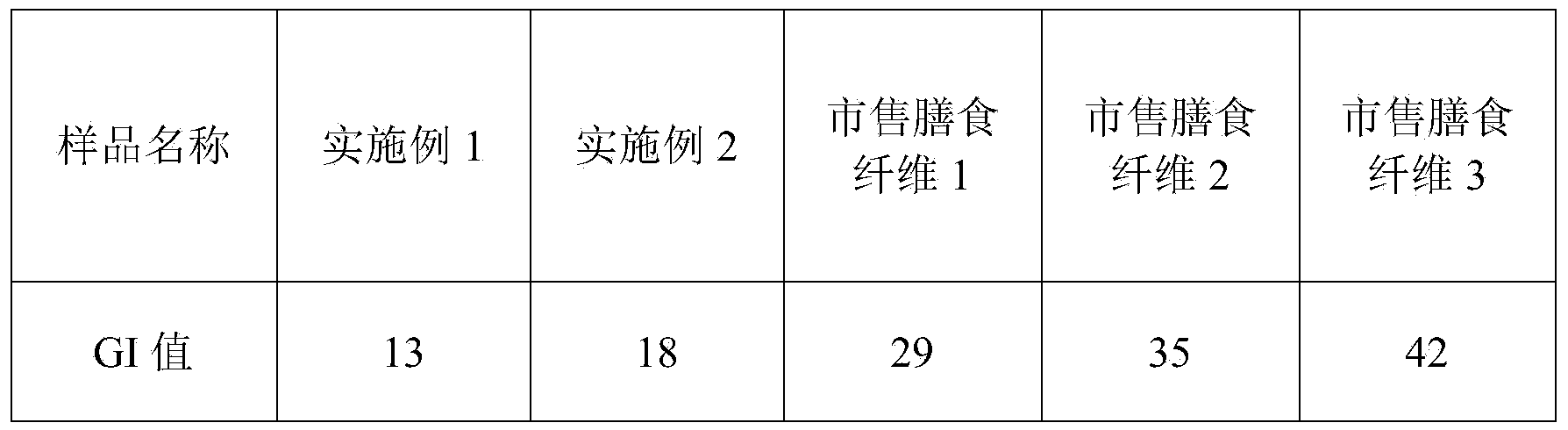

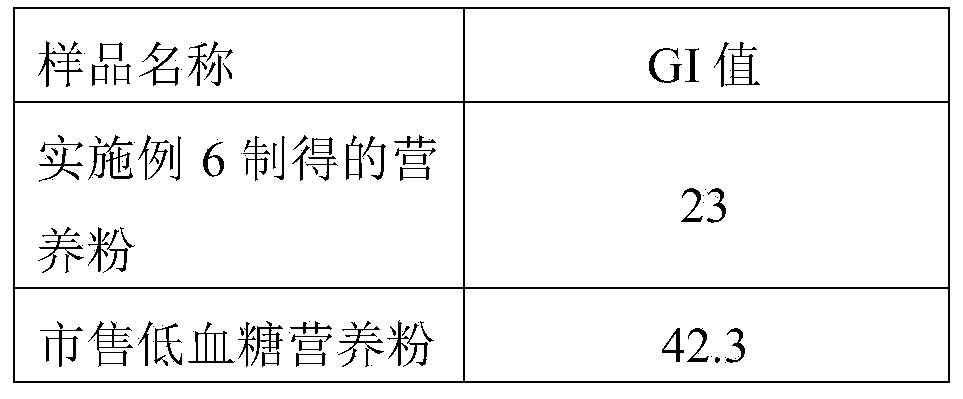

Embodiment 1

[0031] Bake the cornstarch at 110°C for 7 hours, control the DE value to 2, make a 2% solution of roasted dextrin, and add calcium carbonate to the solution, control the stirring speed to 80r / min, so that the pH of the solution is 7. Control the temperature at 60°C, then add 6% α-amylase, hydrolyze for 15 minutes, when the DE value is 20, heat the solution to 100°C, and heat inactivate for 10 minutes. The α-1,6 glycosidic bond content of the obtained hydrolysis intermediate product is 23%, the α-1,2 glycosidic bond content is 1%, the α-1,3 glycosidic bond content is 3%, and the α-1,4 glycosidic bond content is 73%.

[0032] After filtering the solution, add starch branching enzyme to the filtrate, adjust the pH value to 5.0, the temperature is 60°C, the stirring speed is 50r / min, the amount of enzyme added is 5% of the weight of the roasted dextrin before preparing the solution, and the hydrolysis is 0.5% After h, the solution was heated to 100°C and heat inactivated for 10 m...

Embodiment 2

[0035] Bake the cornstarch at 110°C for 7 hours, control the DE value to 2, make a 2% solution of roasted dextrin, and add calcium carbonate to the solution, control the stirring speed to 50r / min, so that the pH of the solution is 7.0, control the temperature at 60°C, then add 0.5% α-amylase, hydrolyze for 30 minutes, when the DE value is 10, heat the solution to 100°C, and heat inactivate for 10 minutes. The α-1,6 glycosidic bond content of the obtained hydrolysis intermediate product is 15%, the α-1,2 glycosidic bond content is 5%, the α-1,3 glycosidic bond content is 8%, and the α-1,4 glycosidic bond content is 72%.

[0036] After filtering the solution, add starch branching enzyme to the filtrate, adjust the pH value to 7.0, the temperature is 40°C, the stirring speed is 80r / min, the amount of enzyme added is 0.5% of the weight of the roasted dextrin before preparing the solution, and hydrolyzed for 3 hours Afterwards, heat the solution to 100°C and heat inactivate for 10...

Embodiment 3

[0039] Bake the potato starch at 130°C for 5 hours, control the DE value to 8, make a 20% solution of roasted dextrin, and add calcium carbonate to the solution, control the stirring speed to 80r / min, so that the pH value of the solution is 8.0, control the temperature at 80°C, then add 3% α-amylase, hydrolyze for 30min, when the DE value is 20, heat the solution to 100°C, heat inactivation for 10min. The obtained hydrolysis intermediate product has 20% α-1,6 glycosidic bond content, 5% α-1,2 glycosidic bond content, 5% α-1,3 glycosidic bond content, and α-1,4 glycosidic bond content of 70%.

[0040] After filtering the solution, add starch branching enzyme to the filtrate, adjust the pH value to 7.0, the temperature is 60°C, the stirring speed is 80r / min, the amount of enzyme added is 3% of the weight of the roasted dextrin before preparing the solution, and hydrolyzed for 3 hours Afterwards, heat the solution to 100°C and heat inactivate for 10 minutes. The finally obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com