High-efficiency electric stirring device

An electric stirring and high-efficiency technology, which is applied to mixers with rotary stirring devices, mixer accessories, mixers, etc., can solve problems such as waste of motor resources, and achieve the effects of low cost, easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

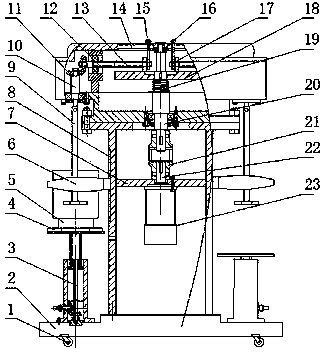

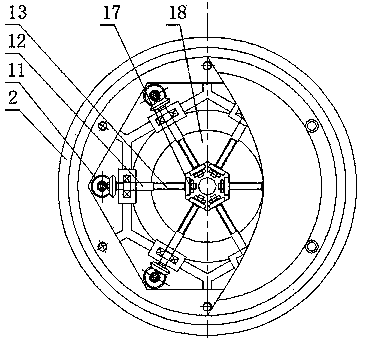

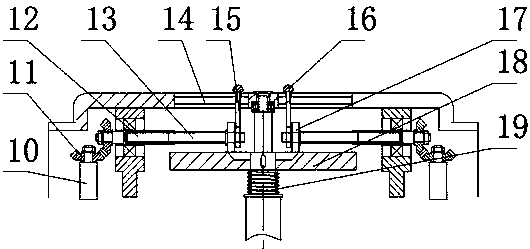

[0014] like figure 1 As shown, the base (2) needs to support the whole device, and the strength requirement is high, and the material is 45 steel with high strength. The cables are drawn out and connected with various external functional devices. The lower surface of the base (2) is equipped with six pulleys (1) that can move freely and can be fixed, so that the whole device can rotate or move the position. The lifting platform (3) is fixed on the base (2) by screws, and each lifting platform ( 3) The distance between them is 60°, corresponding to the position of the stirring paddle (9). Place heat insulation pad (4) and heating ring (5) in turn on the upper surface of the lifting platform, open a through hole on the motor fixing frame (7), lead out the cable of the heating ring (5), and open a clip on the outer wall of the motor fixing frame (7) Holder track (8), so that the container holder (6) moves up and down through the holder track (8), and the container holder (6) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com