Slab crystallizer taper design method

A design method and crystallizer technology, applied in the field of steelmaking-continuous casting, can solve problems such as insurmountable slab shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

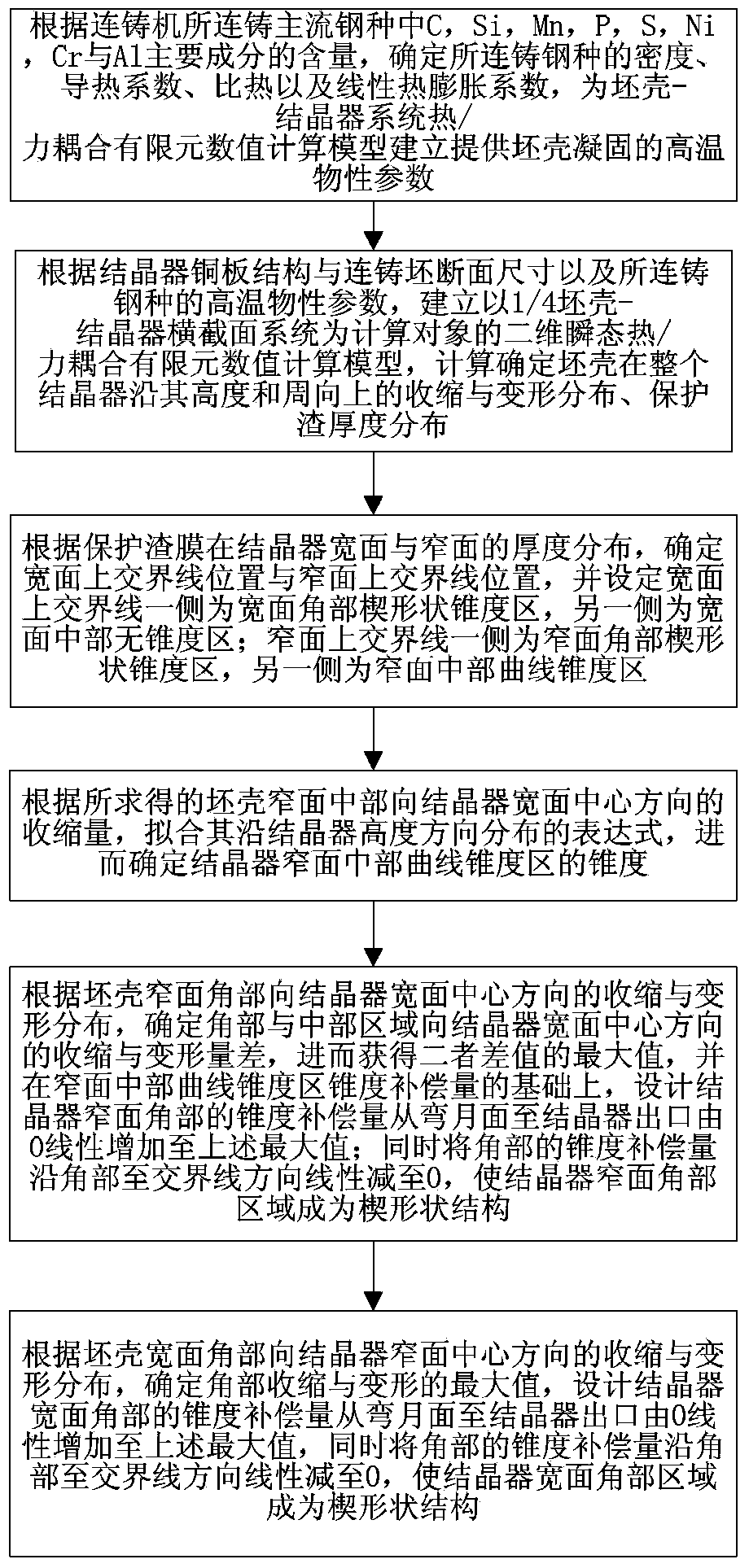

Method used

Image

Examples

Embodiment Construction

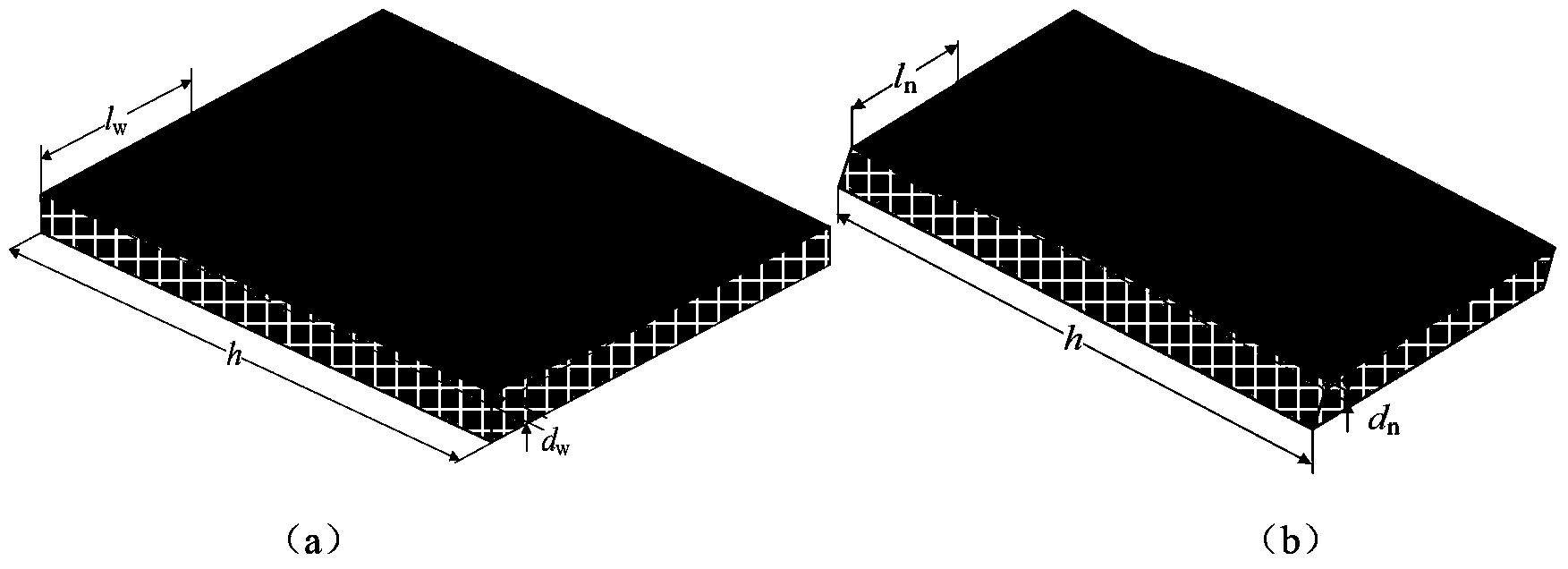

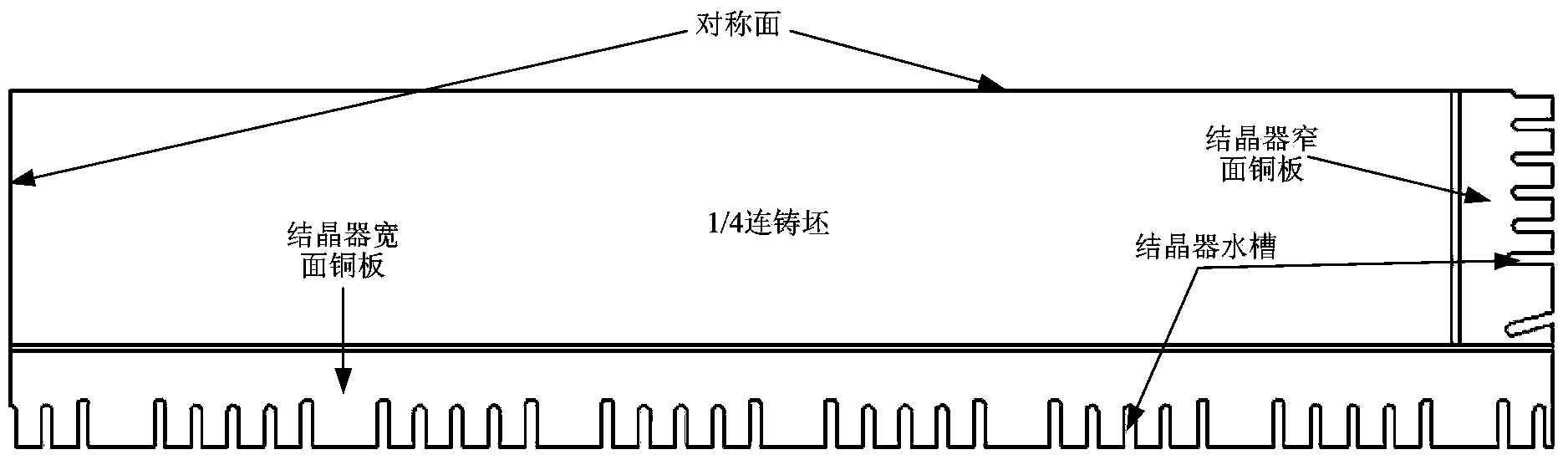

[0068] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0069]The solidification of the billet shell in the crystallizer produces shrinkage and deformation. Affected by the inconsistency of the shrinkage in the height direction of the crystallizer, the billet shell is often insufficiently compensated at the upper part of the mold and excessively compensated at the lower part of the crystallizer. The upper part of the crystallizer is prone to cracks, while the copper plate in the lower part of the crystallizer is severely worn. In addition, since the shrinkage and deformation of the billet shell in the mold are mainly concentrated in the area near the corner of the billet shell, the area near the corner of the billet shell is often caused to significantly reduce the heat transfer rate due to the concentrated distribution of mold slag and air gaps in this area, resulting in The "hot spot" of the billet shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com